Product Variants of Tubular Gage Glass

Standard

CHARACTERISTICS

Standard SCHOTT Tubular Gage Glasses are found in a vast range of applications, from closed tanks and restaurant equipment, to liquid level gages and hydraulic roll film equipment. Most commonly found in low pressure boiler systems, this highly cost-effective option offers reliable performance for a lifetime of use. A saw cut finish, without the need for fire polishing, can be applied to large volumes of products, adding another cost efficiency and manufacturing benefit.

YOUR ADVANTAGES

- Highly economical operation.

- Long service life.

- Ideal for low pressure boilers.

- Saw cut finish available without the need for fire polishing.

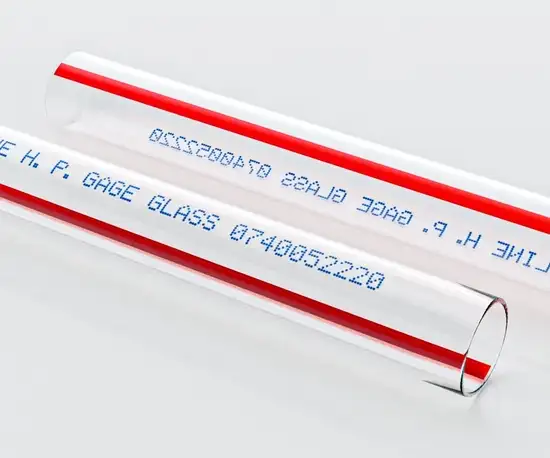

Red Line

CHARACTERISTICS

The Red Line variant offers similar benefits to SCHOTT’s other gage glasses, and can be produced in a range of lengths from 8-24 inches. It offers corrosion resistance up to higher temperatures than the Standard variant, and is a popular choice for use in tanks and reservoirs, as well as low-pressure boilers. A fire polish finish also enhances the safety attributes of the tubing, sealing any small cracks in the end wall and reducing the chance of fractures or unwanted blemishes that might affect performance.

YOUR ADVANTAGES

- Easy and convenient viewing of liquid levels from a distance.

- Wide range of diameters and lengths available.

- Improved corrosion resistance enhancing long-term reliability.

- Fire-polished finish optimizes safety and consistency.

High Pressure

CHARACTERISTICS

Able to work at pressures as high as 460 psi at temperatures up to 150 ºF without corrosion, High Pressure gage glasses specialize in achieving a clear visual indication of liquid flow through a fixed port without contamination or discoloration. With a saw cut and fire-polished end finish, this gage glass can be produced in large volumes, while also benefitting from the highly homogenous technical qualities that ensure reliable performance. With excellent thermal and chemical resistance, diameters up to 1.5 inches (OD) are also possible.

YOUR ADVANTAGES

- Superb visual clarity.

- Performance at pressures up to 460 psi without corrosion.

- Saw cut and fire polished finish.

- Outstanding thermal, chemical and hydrolytic resistance.

- Diameters available up to 1.5-inches (OD).

Heavy Wall

CHARACTERISTICS

When used to measure the flow of crude oil or high pressure gas or water, SCHOTT Heavy Wall Gage Glass has a number of clear advantages. Providing outstanding resistance to acid and alkali, as well as excellent hydrolytic resistance and thermal shock protection, Heavy Wall tubing can withstand pressures of up to 600 psi at lengths of 10-24 inches and diameters ranging from 5/8-1-inch outer diameter. This variant offers stable and reliable operation while viewing oil, water or gas flow rates, with a precise, carborundum saw cut end finish.

YOUR ADVANTAGES

- Very high chemical, thermal and hydrolytic resistance.

- Performance at pressures up to 600 psi without corrosion.

- Carborundum saw cut finish.

- Available in a range of diameters and lengths.

- Suitable for viewing substances including crude oil, water or gas.

Heavy Wall Red Line

CHARACTERISTICS

Heavy Wall gage glass delivers exceptional thermal, chemical and hydrolytic resistance, making it suitable for demanding applications, including crude oil or high pressure water or gas flow. The integration of Red Line technology produces a unique optical effect that makes the liquid levels or gas flow easier to determine at a distance. Benefitting from a precise carborundum saw cut finish, this variant is available in 5/8 and ½ inch diameters in lengths between 12-24 inches.

YOUR ADVANTAGES

- Very high chemical, thermal and hydrolytic resistance.

- Performance at pressures up to 600 psi without corrosion.

- Carborundum saw cut finish.

- Available in a range of diameters and lengths.

- Optimized view of levels and flow of substances including crude oil, water or gas.