Technical Details of Solidur®

SCHOTT Solidur® LEDs are made with high-quality, vacuum-tight housings that deliver complete protection for their internal LED chips, supporting long-term functionality for 'fit-and-forget' applications in harsh environments and safety-critical settings.

Extremely tough, extremely reliable

The benefits of hermetic versus conventional LEDs

The challenge

Conventional LEDs are typically encapsulated using polymer sealing materials. They do little to protect the sensitive internal electronics. But the sealing points of LED lighting modules are of critical importance for the protection of the internal semiconductor components. Even after just one cycle in steam sterilization conditions, as required for medical and dental instruments, organic polymer materials can begin to break down. The weakened seal allows the potential for moisture permeation into the module, a fault that can lead to premature failure for the LED chip inside. This is why the use of standard LEDs is often impossible or extremely limited In applications with high humidity, heat, pressure, or aggressive chemicals, with additional protective housings that need to be designed around the light source.

The solution

Hermetically sealed LEDs represent an answer to the reliability challenge found, for example, in medical and dental applications. The vacuum-tight housings of SCHOTT Solidur® LEDs are made only of inorganic materials, such as metal, glass or ceramics – none of which age or break down over time. As such, the LED packaging offers long-term hermetic protection against moisture, temperature, mechanical impact and pressure and chemicals. The permanent connection of glass and metal therefore averts any danger of internal corrosion or contamination.

Reliability specifications of hermetic Solidur® LEDs

- Autoclaving: Proven functionality for

- oils

- Steam sterilization (2 bar; 273ºF)

- Temperature stability: > 500ºF

- Gas-tightness / Hermeticity: 1 x 10-8 mbar x l/s

- Electric insulation: up to 1 kΩ

- Chemical resistance: High

- Thermal shock stability: -85ºF to 302ºF for 15 cycles

- Refractive index of glass: 1.48-1.58

- Temperature conductivity: High, enabled by ceramic or copper material

|

|

|

Customized white light and color temperature

Specifications

| Solidur® Mini LEDs | Technical Specification |

|---|---|

| Color temperature CCT | 4000 - 6000 K |

| Color rendering index Ra | > 90 |

| Forward current IF max | Up to 350 mA |

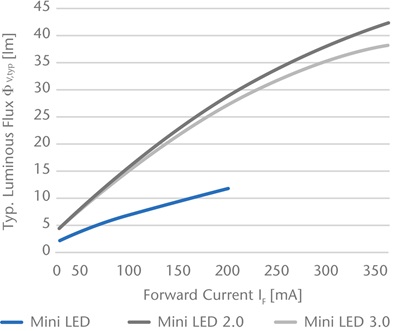

| Luminous flux φv | Up to 16 Im at 100 mA / 42 Im at 350 mA |

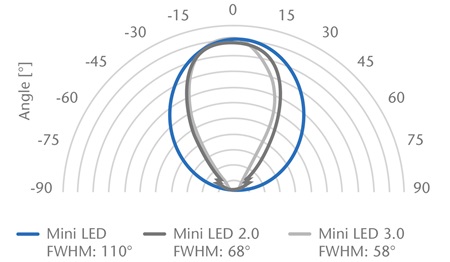

| Viewing angle (FWHM) θv | From 58° to 110° |

| Other colors/wavelengths | Available |

| Size Ø | As small as 2.0 mm |

| Height h | As small as 1.4 mm |

| Autoclavability | Successfully tested to withstand 3500 test cycles at an ambient pressure of 2 bar and a temperature of 134 °C |

| Electrical interfaces |

|

Luminous Flux at Different Forward Currents

Viewing Angles

Specifications

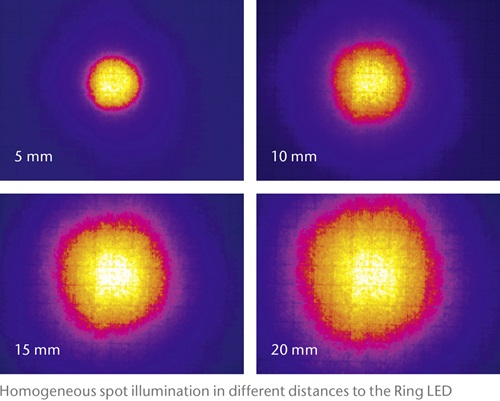

| Solidur® Ring LEDs | Standard length |

|---|---|

| Color temperature CCT |

4000 - 6000 K |

| Color rendering index Ra |

> 90 |

| Forward current IF max. |

Up to 350 mA |

| Luminous flux φv |

Up to 150 Im at 350 mA |

| Viewing angle (FWHM) θv |

Customized, typically 60° - 130° |

| Other colors/wavelengths |

Upon request |

| Size Ø |

Down to 8.4 mm |

| Height h | Smaller than 2 mm |

| Autoclavability |

Successfully tested to withstand 3500 test cycles at an ambient pressure of 2 bar and a temperature of 134 °C |

| Electrical interfaces |

|

Specifications

| Solidur® Transistor Outline LEDs | Technical Specifications |

|---|---|

| Color temperature | 3000 - 6000 K |

| Color rendering index Ra |

> 90 |

| Forward current IF typ |

Up to 700 mA |

| Luminous flux φv |

Typically 10 - 300 Im at 20 - 700 mA, depending on the design |

| Viewing angle (FWHM) θv |

Customized, typically 20 - 130 °C |

| Other colors/wavelengths |

Available as white light LED or colored LED |

| Size Ø | 3.3 to 10 mm |

| Height h | > 2 mm |

| Autoclavability | Successfully tested to withstand 3500 test cycles at an ambient pressure of 2 bar and a temperature of 134 °C |

| Electrical interfaces |

|

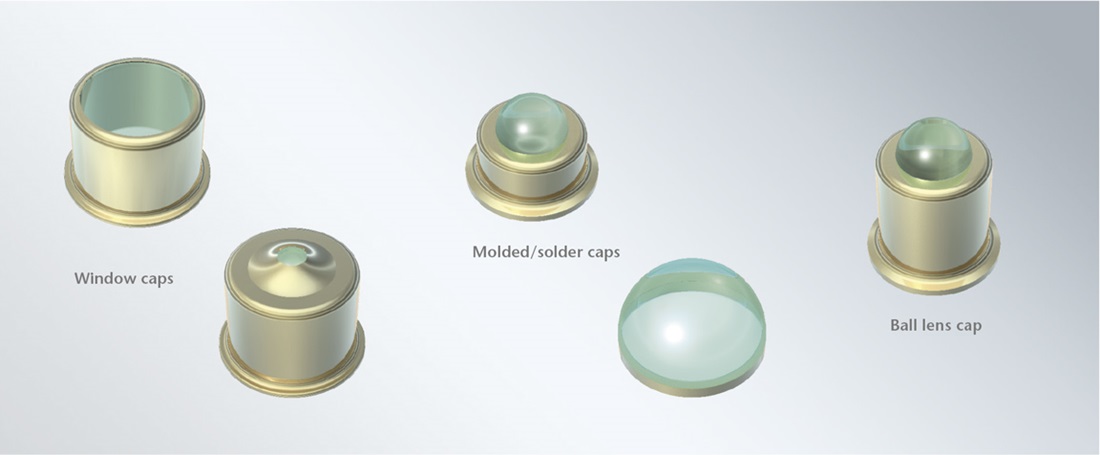

| Lenses / Caps |

|

| Options |

|

SMD LEDs

| Solidur® SMD LEDs | Technical Specifications |

|---|---|

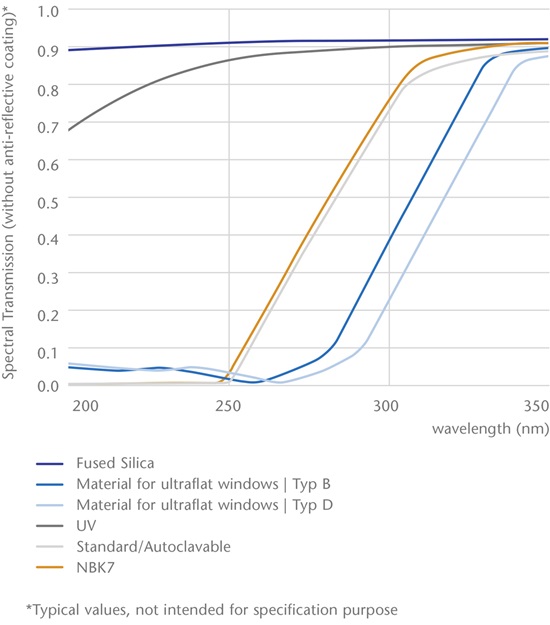

| Spectral range | UVB/C |

| Wavelength l | 265 nm, 280 nm, 310 nm |

| Forward current IF max. | Typically max. 700 mA |

| Radiation flux φv | Customized |

| Other colors/ wavelengths | Available |

| Size | Down to 3.5 x 3.5 mm2 or a diameter down to 2 mm |

| Height h | < 1.5 mm |

| Hermeticity | yes |

| Autoclavability | yes |

| Electrical interfaces |

|

| Options |

|

| Features of Solidur® SMD UV LEDs | Your Benefits |

|---|---|

| Metal-Glass or Ceramic-Glass package components | Virtually no degradation caused by UVB/C radiation |

| Matching thermal expansion of components |

|

| Encapsulation material | Increase of efficiency up to 50 % depending on design |

| Flat window and lens caps | Beam shaping according to your application |

| Wafer level production possible | Cost effective production |

| Through-hole and SMD package concept | High flexibility in assembly and electrical connection |

Tonya Durkin

Senior Sales Manager