Technical Details of Optical Glass

Properties of Optical Glass

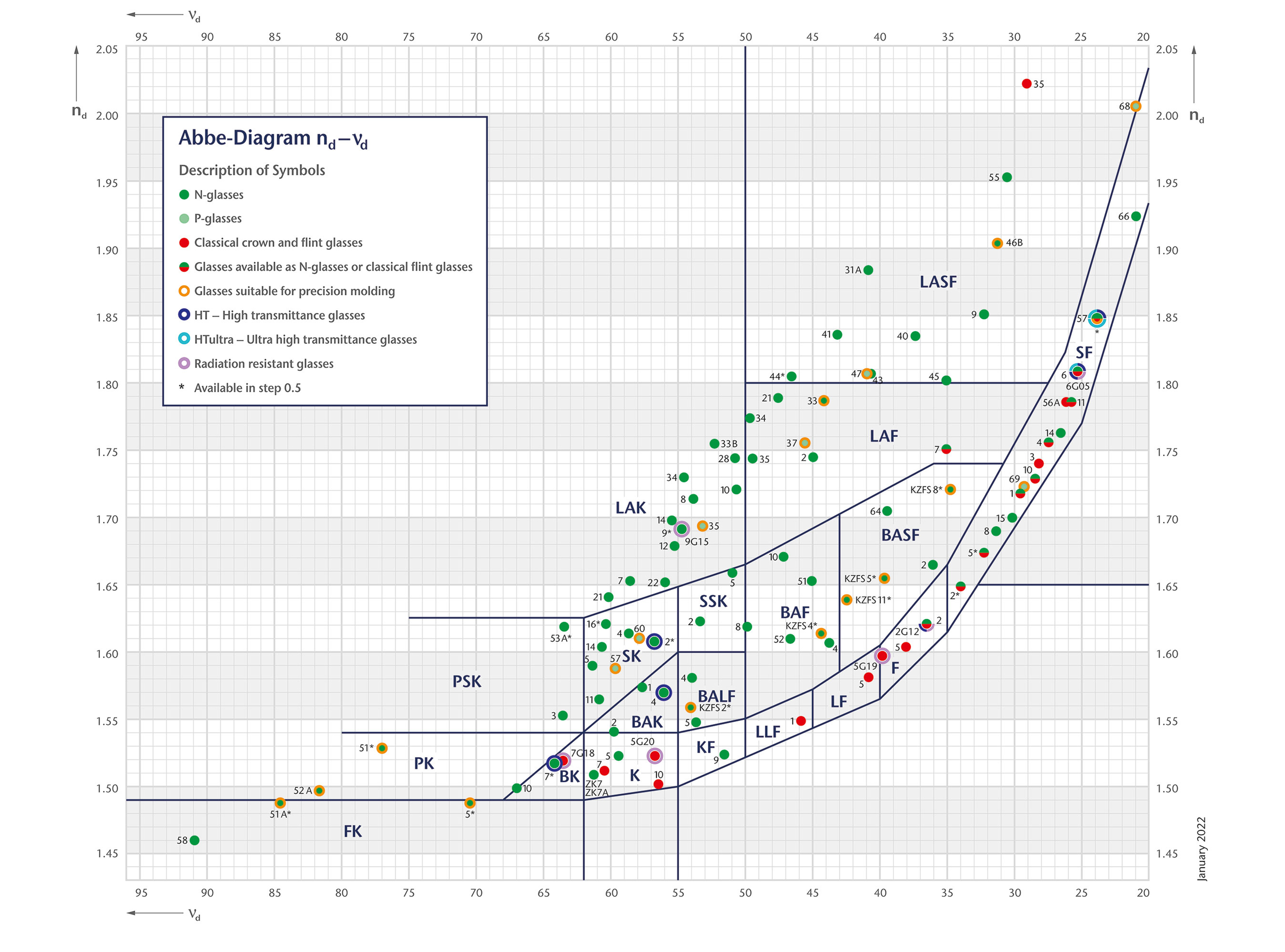

Tolerances for refractive index and Abbe number (according to ISO 12123)

| nd | νd | |

|---|---|---|

| Step 0.5* | ± 0.0001 (NP010) | ± 0.1% (AN1) |

| Step 1 | ± 0.0002 (NP020) | ± 0.2% (AN2) |

| Step 2 | ± 0.0003 (NP030) | ± 0.3% (AN3) |

| Step 3 | ± 0.0005 (NP050) | ± 0.5% (AN5) |

Forms of Supply

We master the entire value chain an offer various supply forms. For specifications and tolerances please view our ‘Optical Glass – Catalog’ in the download section.

Raw Glass

- Blocks: Blocks have up to five unworked, as-cast surfaces. Usually, at least one surface has been worked. The edges are rounded. Blocks are fine annealed and thus suitable for cold working.

- Strips: Strips normally have unworked or ground surfaces and broken or cut ends. Strips are either coarse annealed or fine annealed. Coarse annealed strips are only suitable for reheat pressings

- Rods: SCHOTT offers the widest range of rods with different geometries, formats and materials.

Cut Blanks

- Plates: Plates are quadrilateral fabricated parts. All six sides are worked; the edges have protective bevels.

- Round plates: Round plates are cylindrical parts for which the diameter is larger than the thickness. Round plates are machined on all surfaces.

- Worked rods: Worked rods are cylindrical parts that are machined on all sides. The length of a rod is always greater than its diameter.

- Cut prisms: Cut prisms are prisms produced by cutting and can be ground on all sides. Equilateral and non-equilateral prisms can be produced in various forms (ridge, penta, triple prisms …) using different fabrication technologies.

Pressings

- Pressed blanks: Pressed blanks are hot formed parts with mainly round cross sections, defined radii and bevels.

- Pressed prisms: Pressed prisms are hot formed parts with angled, prismatic shapes. Other dimensions are possible upon request

We also offer high-precision optical components made of optical glass.

Optical Properties:

- Refractive index with tolerances

- Abbe value with tolerances

- Refractive index homogeneity

- Internal transmission

- Color code

Internal Properties:

- Striae

- Bubbles and inclusions

- Stress birefringence

Unless specifically requested, SCHOTT optical glass will be delivered in refractive index/Abbe number step 3/3 with a standard test report. The refractive index of all parts of a lot will not deviate by more than ±1 x 10-4 (± 2 x 10-4 for pressing) from the test report.

Quality Assurance

SCHOTT is both ISO 9001 and 14001-certified and can be your trusted partner. Our optical glass goes through a stringent quality inspection before delivery. The production of optical glass is continuously monitored at all stages in addition to an elaborate final inspection.

Delivery lots are tested for refractive index scattering, stress birefringence, striae and bubbles according to DIN ISO 10110. A test certificate in accordance with DIN EN 10204 documents the standard supply quality. Upon request, we can also supply test certificates with increased accuracy. For high homogeneous cut blanks, we confirm homogeneity through interferometry.

Properties of High Homogeneity Glass

Specifications

SCHOTT offers glasses in five levels of homogeneity. Thanks to a carefully controlled manufacturing process, glass pieces in H4 quality have a maximum peak to valley refractive index variation of 2 x10-6, while the quality level H5 achieves a value of 1 x10-6. The maximum variation of refractive index is expressed in peak to valley values in accordance with ISO 12123.

Homogeneity of optical glass

Increased requirements for refractive index homogeneity comprise five classes in accordance with the standard ISO 10110 and ISO 12123.Homogeneity classes and their maximum variation of refractive index as well as applicability can be found in the ‘Optical Glass Catalog’, available in the download section. (1.4. Refractive Index Homogeneity)

SCHOTT offers a selection of optical glasses as fine annealed cut blanks in high homogeneities from stock. An overview of available glass types, dimensions, and homogeneity levels can be found in our ‘Optical Glass Catalog’, available in the download section. (1.4.1 High Homogeneity Glass available from stock)

Properties of i-Line Glass

Forms of Supply

We offer i-Line glasses up to 300 mm in diameter and thicknesses up to 100 mm. Customized dimensions are possible upon request.

Customized shapes include:

- CNC machined

- Coated

- Polished

- Sub-assembled

Refractive Index Homogeneity

The maximum variation of refractive index depends on the glass dimension.

- Ø 150 mm with a maximum variation of 0.5 · 10–6

- Ø 200 mm with a maximum variation of 1.0 · 10–6 (H5)

- Ø 250 mm with a maximum variation of 2.0 · 10–6 (H4)

We also offer high-precision optical components made of i-Line glasses.

Specifications

Homogeneity, bubbles/inclusions, and dispersion values can be found in the ‘Optical Glass – Catalogue', available in the download section.

Quality Assurance

- i-Line glass is subject to a 100% control of homogeneity, stress birefringence, striae, bubbles, and inclusions.

- Refractive index and transmittance are statistically controlled.

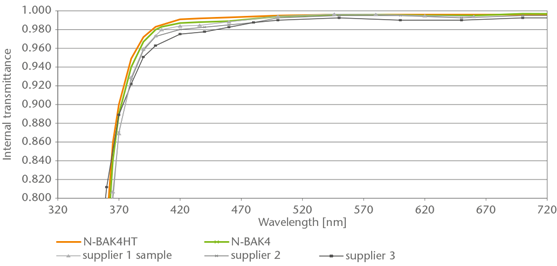

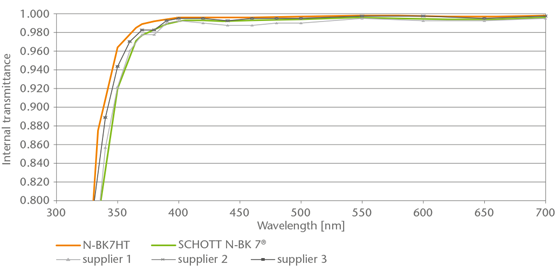

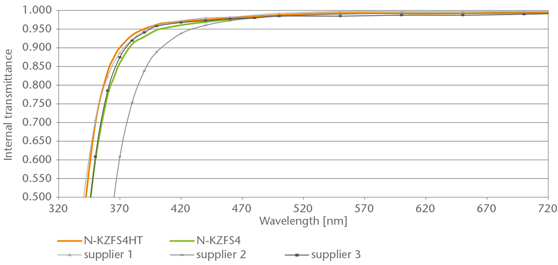

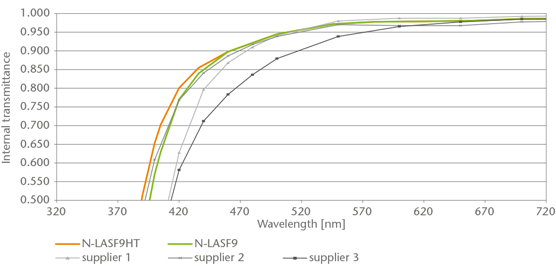

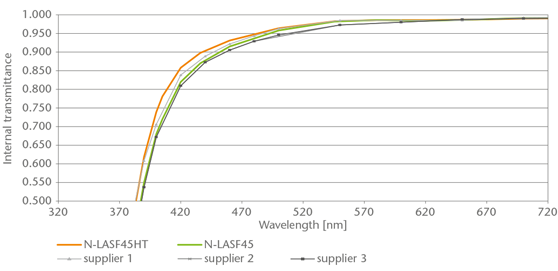

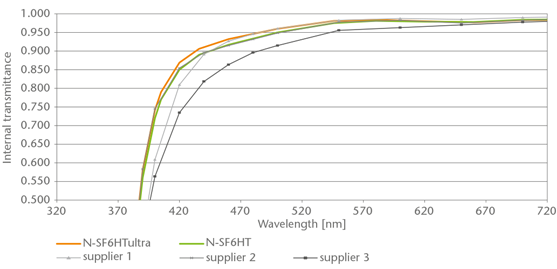

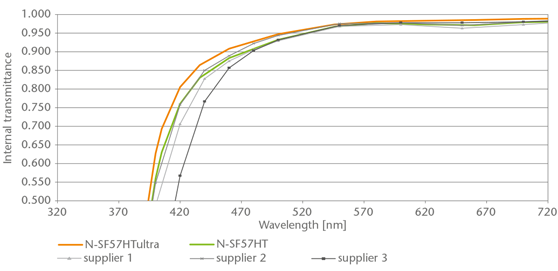

Properties of HT and HTultra Glass

* Wavelength for transmittance 0.7 and 0.05

** 10 mm thickness, 400 nm wavelength

Overview of High Transmittance***

N-BAK4HT, nd = 1.5883, vd = 55.98

N-BK7HT, nd = 1.51680, vd = 64.17

N-KZFS4HT, nd = 1.61336, vd = 44.49

N-LASF9HT, nd = 1.85025, vd = 32.17

N-LASF45HT, nd = 1.80107, vd = 34.97

N-SF6HTultra, nd = 1.80518, vd = 32.36

N-SF57HTultra, nd = 1.84666, vd = 23.78

***Whereas the internal transmittance curves of standard optical glasses in the datasheet comprise median values for the glass types HT and HTultra, glass internal transmittance curves are guaranteed minimum values for internal transmittance in the visible spectrum. Graphics are valid for 25 mm sample thickness.

Forms of Supply

HT and HTultra glasses are available in various supply forms:

Components

- Polished prisms with dimensions from 10 mm - 200 mm

- Lenses with dimensions from 10 mm - 90 mm

Pressings

- From 5 mm - 320 mm in diameter and center thickness from 2 mm - 100 mm

Raw Glass

- Strips with dimensions ≤ 50 mm

- Blocks with dimensions 190 mm x 180 mm x 140 mm

Other supply forms and dimensions are possible upon request (depending on glass type).

We also offer high-precision optical components made of optical glass.

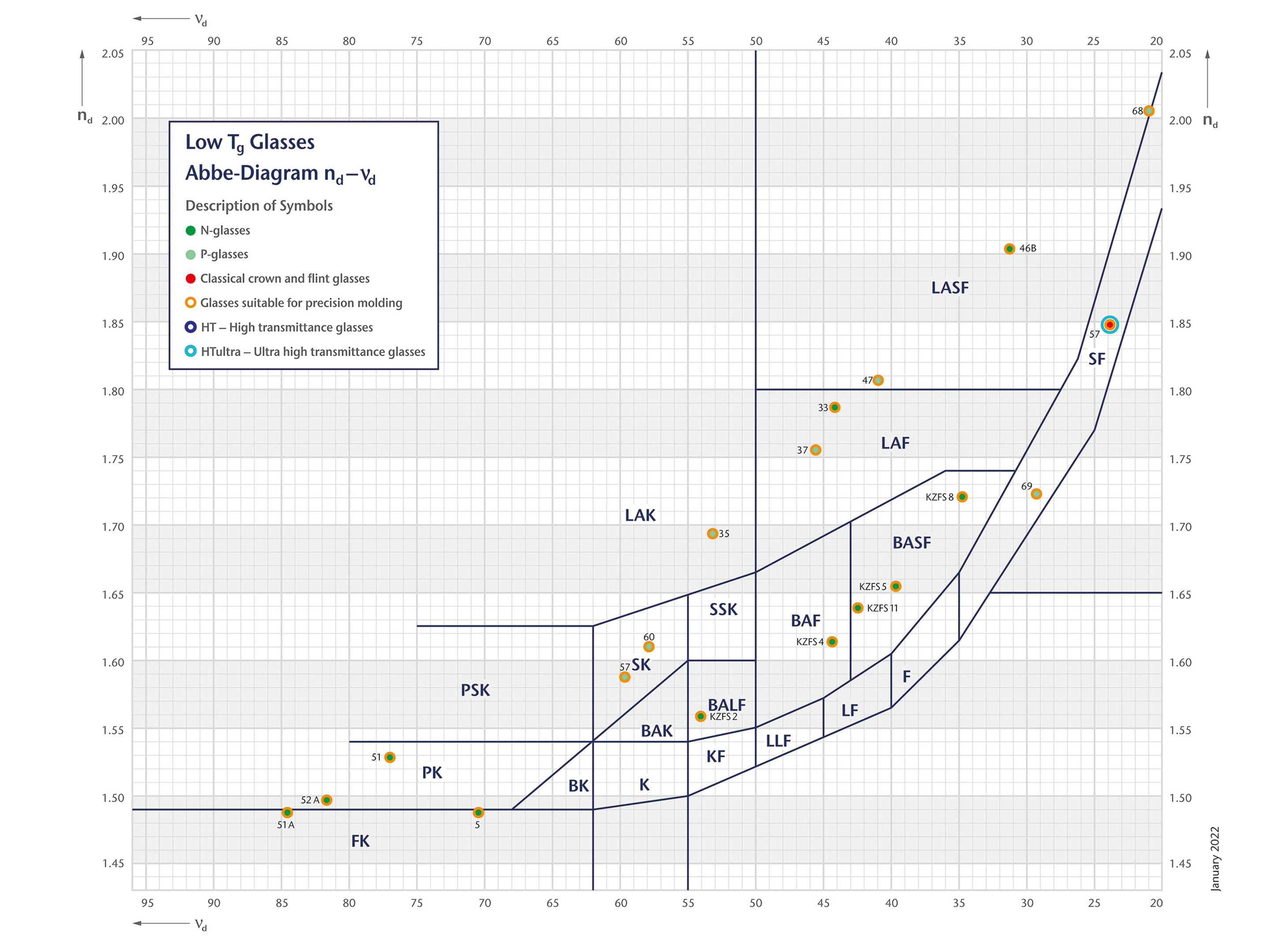

Properties of Low Tg Glass for Precision Molding

Low Tg glasses have a glass transformation temperature suitable for precision molding and a special glass composition to decrease the tendency for devitrification and to reduce the reaction with mold materials within the molding temperature range.

During precision glass molding, a polished or fire-polished preform is shaped into a final geometry, while conserving its surface quality. The typical temperature range for the molding process is between 500-700°C, enabling the extension of the operating lifetime of the mold material and a significant time reduction of the press process.

Materials

For specifications and tolerances please view our ‘Optical Materials for Precision Molding Datasheet’ in the download section.

Forms of Supply

Low Tg glass for precision molding is available in various supply forms:

Optical glass rods

- Various shapes with < 1 mm – 7.5 mm in diameter and length up to 1,000 mm

- Various surface qualities with > 7.5 mm – 12.5 mm in diameter and length up to 140 mm

Ball lenses

- Different formats with 0.8 mm - 320 mm in diameter

Other supply forms and dimensions are possible upon request.

Properties of Radiation Resistant Glasses

For use in surroundings with high ionizing radiation

SCHOTT Advanced Optics offers a variety of radiation resistant glass types with different dispersion properties:

- BK7G18

- LF5G19

- LF5G15

- K5G20

- LAK9G15

- F2G12

- SF6G05

These glass-types are suitable for use in surroundings with high radioactivity. The radiation resistance differs with each glass type, whereas it can be extremely high for some types such as the BK7G18 and LF5G19.

Please note that all radiation resistant glasses except LAK9G15 are usually available in standard bubble quality according to the optical glass catalog. The total allowable cross section of bubbles in LAK9G15 is 0.1 mm2 per 100 ccm for bubbles larger than 0.03 mm in diameter. A large amount of inclusions < 0.03 mm diameter is typical for this type of glass and cannot be avoided by production means.

Forms of Supply

Radiation resistant glasses are available in various supply forms:

- Cut blanks

- Pressings

- Rods

Customized dimensions are possible upon request.

We also offer high-precision optical components made of radiation resistant glasses

Quality Assurance

- Test certificates for refractive index and dispersion and detailed transmittance data upon request.

- Accurate measurement microscopes and stress measurement setups according to the 'de Senarmont' method for the examination of internal quality and stress birefringence.

- Interferometer with aperture up to 24 inches in diameter for optical homogeneity inspection.