Microfluidic solutions

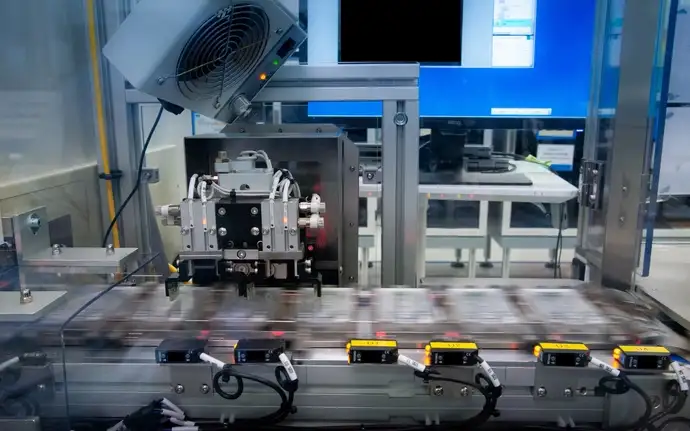

SCHOTT MINIFAB is where experience and expertise meet innovation in microfluidic solutions. With more than 20 years of experience, we are experts in designing, developing, and manufacturing microfluidic systems aimed at diagnostic and life science applications. Having dedicated years to mastering the intricacies of this space, we bring a toolbox full of proven design solutions that meet the most challenging applications. We take pride in our ability to bring our customers’ technologies to life.

Fit-for-purpose design solutions

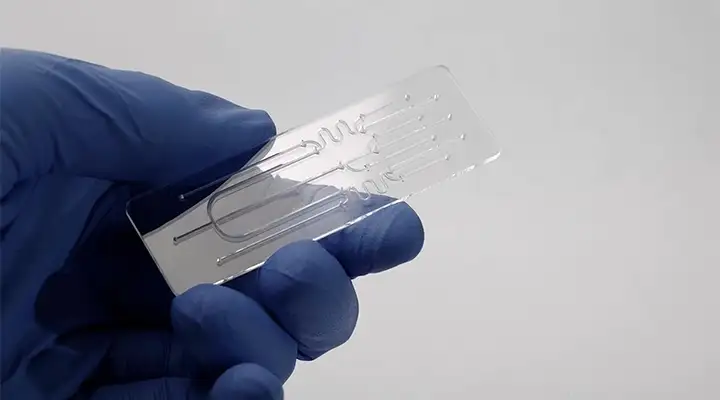

In a world where off-the-shelf products often fall short and fully customized solutions mean lengthy lead times, we present a third option that offers the best of both worlds. Benefit from our extensive expertise and purpose-built solutions, designed to accelerate your time to market without compromising on your specific needs. As a seasoned contract developer and manufacturer, we draw on a wealth of insights from thousands of projects, equipping us to offer a robust library of design solutions that seamlessly adapt to your unique program.

Our distinctive approach lies in our modular design philosophy. We provide ready-to-use design modules that serve as the building blocks for a comprehensive, cohesive product. This approach ensures rapid deployment and integration, facilitating quicker market entry and operational efficiency. Yet, the true beauty of our solutions lies in their flexibility — these modules can be tailored and combined in myriad ways to create a product that is precisely aligned with your requirements.

Additional cartridge or device features include:

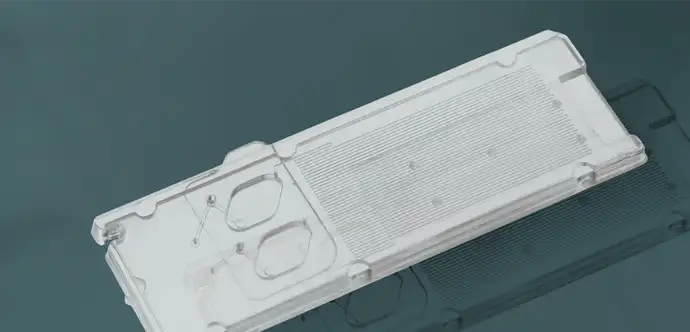

Cartridge shell

Our cartridge shell offers both form and function - protect your blisters and precise features from damage and customize the branding and look of your product at the same time

Elastomeric valve

Our elastomeric valve membranes enable complex fluidic workflows on cartridges, with options for pneumatic or mechanical actuation. Available in various materials, they integrate seamlessly via solvent bonding, laser welding, or PSA bonding, ensuring reliable sealing and precise fluid control.

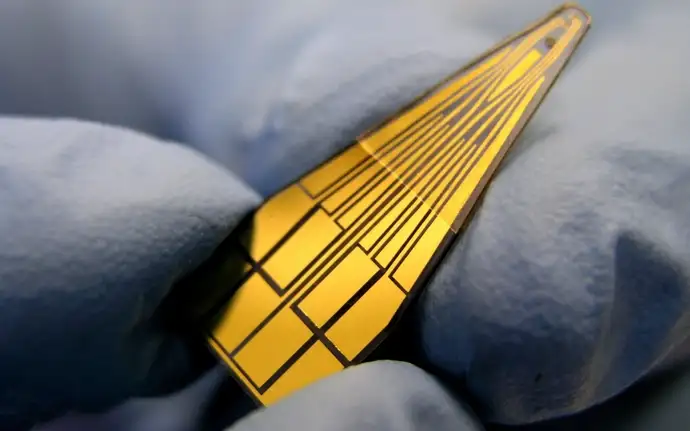

Glass components

Our glass subcomponents are made from SCHOTT NEXTERION® glass substrate, ideal for optical detection, offering high accuracy, durability, and chemical resistance. Custom designs via precision manufacturing ensure optimal performance, with coatings available for specific applications. Various integration solutions streamline incorporation into systems, ensuring compatibility and ease of use.

Dry down slip

We've developed a plug-and-play solution for integrating dry-down reagents. Our Dry Down Slips allow you to dispense, dry-down and process your reagents off-line before integrating with your cartridge with a simple in-line bonding step.

Trusted ally committed to your goals

Our ultimate goal is to ensure our customers not only meet their objectives but surpass them, delivering consumables that perform flawlessly and contribute to enhanced diagnostic and research outcomes. Partner with us, and let our expertise propel your success.

Get your free whitepaper!

Learn valuable insights into the critical phases of developing diagnostic tools and life science research, with our whitepaper, Unlocking Success: How to Navigate the Unknowns in Microfluidic Product Development.

FAQs

We offer different functionalities, materials and processes to help our customers move from design to volume production. We have unparalleled expertise in glass and polymer substrates and vast experience integrating channels, mixers, valves, pumps, sensors or reaction chambers and reagent storage to help solve complex microfluidic challenges.

Yes, we work closely with our customers to create customized microfluidic solutions that meet the highest quality for manufacturability.

Material selection should be based on analysis of the device’s intended use, the durability of the material and cost. Four of the most common materials used are silicon, glass, polymer and hydrogels. You need to use trusted materials for the construction of the microfluidic device. More importantly, you need a partner that has extensive experience on which to lean. By partnering with SCHOTT MINIFAB you will back by leader in glass manufacturing for over 140 years.

We follow a flexible and iterative development process to reduce risk throughout design and prototyping, ensuring your microfluidic consumable meets your required performance criteria for reliability and reproducibility.