Meet Quotient: Transforming Blood Diagnostics

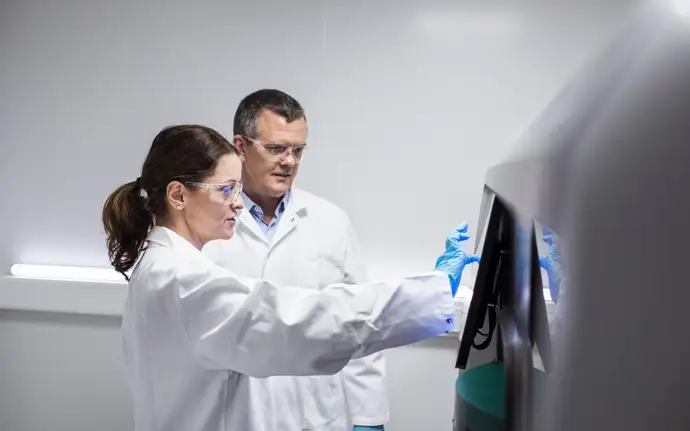

Swiss diagnostics company AliveDx has a clear mission: To create the world’s most efficient blood test.

As a SCHOTT customer, the company's COO in 2020 Ed Farrell shares with us how this goal drives him onward each and every day, and how specialty glass is helping the team to achieve this goal.

Let me share with you why I put so much energy into my work and why I find glass to be so much more than a manufacturing material.

Ten years ago, I lost a family member to cancer. After that difficult time, I thought a lot about the cost of diagnostics testing and the current approach to testing – one test at a time. I believed that with a different approach it could be possible to lower the cost and perform more tests at one to allow for early detection of different conditions.

I joined AliveDx with the aim of changing the status quo.

Our vision is to make the world’s fastest, most reliable, and cost-efficient transfusion diagnostics tool a reality. We are developing systems that can identify diseases like HIV or hepatitis B without delay, and matching blood types between donors and recipients quickly and efficiently, all without medical practitioners having to worry about costs.

A single blood sample is all that is needed to produce meaningful health and diagnostic information.

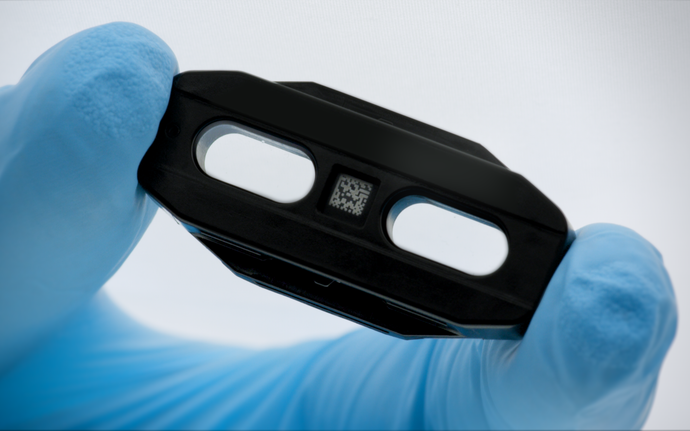

That’s where MosaiQ comes in. MosaiQ is a diagnostic platform that automates blood group typing and antibody profiling. MosaiQ analyzes the blood sample using the red blood cells and antibodies we have printed onto glass microarrays. Each of these identical microarrays is as small as a fingernail and as thin as a human hair, yet each array offers space for 132 samples.

It is possible to achieve such precision within a small space because the microarrays are based on a transparent coated glass substrate (NEXTERION®) to which blood cells and antibodies and antigens adhere. These substrates, or coated glass wafers, are provided by SCHOTT.

A shared goal

We’ve worked closely with SCHOTT for many years now. If we were to lay all the NEXTERION® glass wafers that we have processed during our relationship side by side, they would cover 20 tennis courts. And remember: A single glass on a microarray is barely the size of a fingernail!

It is through my work with SCHOTT that I have truly learned the sheer potential of glass and glass-derived products. I had previously worked with scientific glassware in diagnostics, but I had never given the glass itself any thought. Now, that has all changed.

Glass has helped make possibly one of the most innovative and efficient transfusion diagnostics platforms ever that offers the highest throughput and productivity per square meter lab space in today’s transfusion diagnostics setting. Through comprehensive analysis of blood samples, we will be able to supply better, more reliable test results. At the same time, we will provide relief from the ever-growing cost pressures labs in hospitals and blood donation centers encounter on an ongoing basis.

Four questions to...

Marcel Fischer, Head of Project Management for the product group NEXTERION® at SCHOTT

What makes AliveDx unique in your eyes?

MosaiQ by AliveDx is a disruptive technology with regard to diagnostics performance, costs, and speed. As a customer, they are thus a perfect fit for our own positioning and that of our product NEXTERION®. We, too, are an innovation driver through our processing- and coating technologies and a reliable partner for the growing diagnostics market.

Why do you think did AliveDx decide to partner with SCHOTT?

We can supply high-quality coated substrates in large volumes. That is key because reproducibility of test results is a decisive factor for a medical diagnostics company like AliveDx. We also offer extensive knowhow when it comes to coatings and applications. In addition, with the acquisition of Minifab, we are integrating new capabilities in polymer cartridges for point-of care and diagnostics, which allow us to offer the complete range of potential solutions that innovative customer like AliveDx find very helpful.

How customized are the glass substrates that SCHOTT supplies to AliveDx?

We manufacture the substrates according to our customer’s requirements. The coated wafers we supply to AliveDx for antibody profiling and blood typing are both absolutely one of a kind. We worked closely with the customer for years to develop them. The end result was that we were able to develop two innovative coatings that allow blood cells and antibodies to adhere to the wafer as needed and since produce these products successfully in a highly scalable process.

What have you personally come to learn from your work with AliveDx?

In particular, how a start-up operates and “thinks”. AliveDx is very fast and ambitious – it was inspiring for us, too. Quite simply, it is a lot of fun working with a company that is truly on a mission to achieve something great.

Photos: SCHOTT/Fabian Stürtz

June 2020