Glass Micro Bonding by SCHOTT Primoceler

Ultra reliable hermetic sealing

Glass Micro Bonding is an innovative process that opens new doors for the wafer-scale sealing of electronics with all-glass hermetic electronic packages. The hermetic seal is formed using an extremely precise laser to fuse glass-to-glass by melting only the cross section where the glass meets – an area of just a few microns – while leaving all other surfaces untouched.

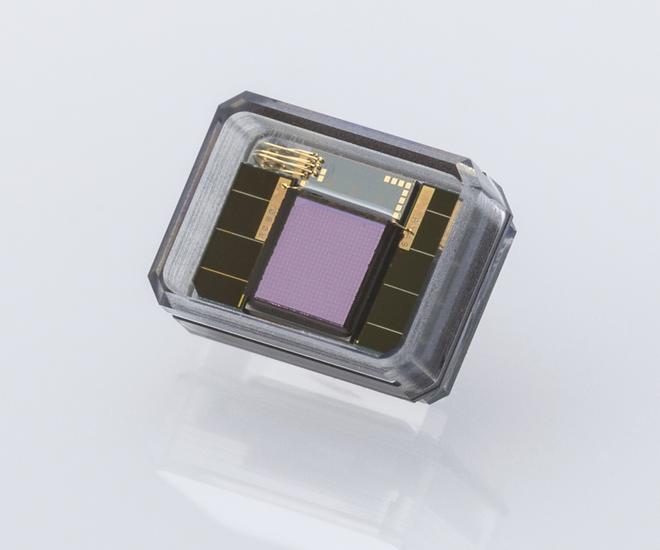

Ultra miniature wafer-level chip scale packaging

Components sealed with Glass Micro Bonding can be as small as a few cubic millimeters. The technique has flexible implementation possibilities and can be performed on a chip-scale all the way up to wafers as large as 12 inches, making it simple and cost-effective to scale up for high-volume manufacturing.

Supporting innovation with next-generation hermetic sealing

Glass Micro Bonding is a revolutionary addition to SCHOTT’s portfolio of hermetic sealing methodologies. If reliable encapsulation, biocompatibility, miniaturization, or production efficiency are on your requirements checklist, Glass Micro Bonding could be a fit for your application. SCHOTT offers a collaborative development process to help support the creation of expertly engineered finished customer components.

We are certified

SCHOTT Primoceler’s manufacturing processes are constantly optimized to allow efficient production and component traceability. Our entire staff participates in further developing the ISO 9001 quality system on a continuous basis.

To protect your privacy, external content will only be loaded with your consent. Refer to our Cookie Policy for detailed information.

Related products

Want to know more? Let's talk

Whether you need more information, samples, a quote, or advice for a project, I would be delighted to talk to you.

Contact us