Hydrogen

Hydrogen applications face very challenging conditions

Hydrogen is more prominent in its sustainability potential since it forms water rather than harmful exhaust gases after combustion. It may be one of the cleanest forms of energy on the market.However, hydrogen applications face challenging conditions. These include pressure levels up to 1,000 bar, extreme temperatures from -253 °C (liquefied hydrogen) up to 650 °C - 950 °C (Solid Oxide Electrolyzer and Fuel Cells), as well as an inherent risk of explosion. This is because hydrogen has a very low ignition energy and a significantly wider flammability range compared to other fuels like methane, propane, and petrol.

Furthermore, as this element is so light, it occupies a high volume at normal temperatures and pressures. Thus, transporting hydrogen efficiently requires prior compression or liquefaction.

New developments in the hydrogen supply chain from source to end use

Although hydrogen has been used in industrial refining processes for decades already, there are a multitude of new application possibilities, such as the generation of green hydrogen via water electrolysis, conversion into synthetic fuels, and usage in fuel cell electric vehicles.These applications will require completely new systems and technologies, as well as reliable materials and components that meet the design requirements. When deployed in fields like mobility or residential electricity supply, sensors are widely used to monitor the safety of the whole system, including the hydrogen tank. The robustness, safety, and longevity of the sensor components are vital to prevent severe accidents. Gastight sensor seals and housings can help provide the required protection.

Hydrogen value chain (illustrative)

Safety and reliability in the hydrogen value chain

Watch how SCHOTT specialty glass can improve safety and efficiency along the hydrogen value chain.Technology designed to improve safety and efficiency

As a world-leading supplier of innovative hermetic feedthroughs and components, SCHOTT helps to improve efficiency and safety along the entire hydrogen value chain – from generation over conversion, transportation and storage, up to hydrogen usage in mobility and stationary applications. SCHOTT offers hermetic components such as feedthroughs required to transmit power or valuable data and information provided by sensors, hermetic optical access for process monitoring, and sealing materials for hydrogen applications.Generation

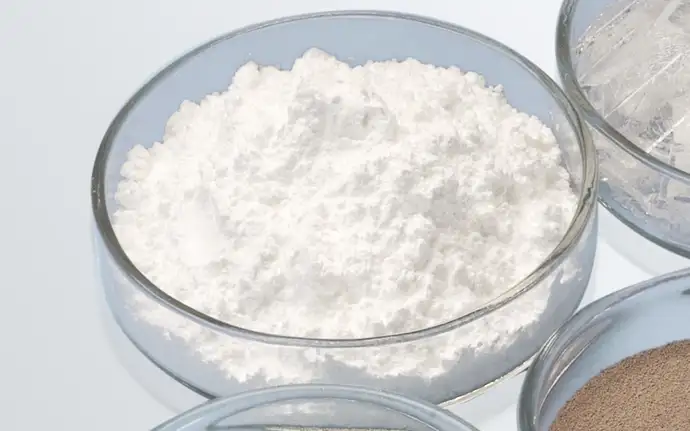

SCHOTT sealing glasses create a hermetic seal in Solid Oxide Electrolyzer Cell (SOEC) stacks. Thus, they enable the secure and stable combination of multiple cells into a high-performance cell stack at temperatures between 650 °C and 950 °C. As a sealing material, glass not only offers excellent hermeticity and very high temperature resistance, but also exceptional chemical stability and higher electrical resistance at operating temperatures. SCHOTT offers a large variety of high-purity glasses with optimal reproducibility thanks to dedicated melting and grinding facilities.

Generation and conversion

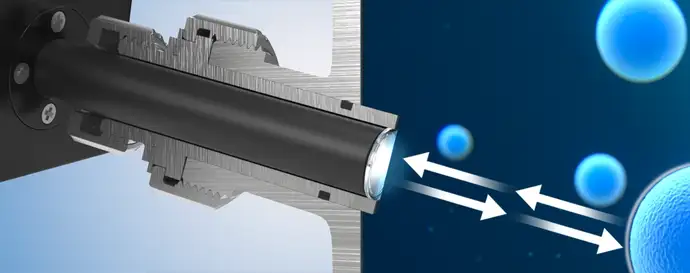

ViewPort® Process Analytical Technology (PAT) components are gastight optical sensor feedthroughs that act as receptacles for Raman or fluorescent probes. They are equipped with a hermetically sealed high-precision optical window and can be securely connected to standard ports (e.g. Ingold, PG13.5). By allowing for inline or in-situ monitoring, ViewPort® components enable increased yields and real-time process control and automation in Power-to-X (bio) reactor or pyrolysis reactor applications.

Transportation and storage

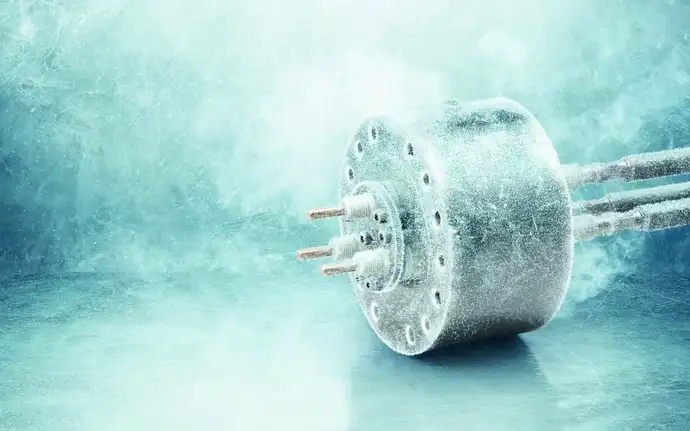

SCHOTT’s feedthroughs for liquid and compressed hydrogen applications enable a safe, explosion-proof supply of electrical power, control, and instrumentation signals to, for example, expanders, compressors and submerged pumps. Unlike polymer-based products, SCHOTT Eternaloc® feedthroughs are hermetically sealed using only inorganic, non-aging materials, making them maintenance-free even after many years of use.

SCHOTT has several decades of experience with cryogenic gas. Since 1985, safety-critical Eternaloc® feedthroughs have proven their reliability in thousands of liquefied gas applications worldwide. They withstand extremely high pressure and thermal shocks, and remain absolutely leak-tight, even in accidents. They also comply with numerous explosion-proof requirements such as ATEX and IECEx.

End use

For mobility usage, SCHOTT offers a broad portfolio of truly hermetic sensor feedthroughs and packages particularly suited for harsh-environment applications. Thanks to superior pressure, temperature, corrosion resistance, and the minimized risk of short circuits and electrical leakage, they offer long-term peace of mind for safety- or performance-critical applications.

SCHOTT’s glass-to-metal sealed housings have been used for decades to reliably protect sensitive automotive electronics and sensors such as temperature, pressure, gas, and fluid sensors. In the area of hydrogen, SCHOTT’s glass-to-metal feedthroughs are already used for in-tank temperature sensors in fuel cell vehicles (FCV).

For stationary usage, SCHOTT sealing glasses have had a proven track record in Solid Oxide Fuel Cell (SOFC) stacks since the 1990s. End applications for our sealing glasses range from decentralized power generation systems up to fuel cell-based cruise ships.