Technical Details of B 270®

Market-leading transmittance and thickness range

Material properties of B 270®

1. Optical properties

| Optical Properties | Value |

|---|---|

| Refractive index* ng | 1.5341 |

| Refractive index* nF' | 1.5297 |

| Refractive index* nF | 1.5292 |

| Refractive index* ne | 1.5251 ± 0.001 |

| Refractive index* nd | 1.5230 |

| Refractive index* nD | 1.5229 |

| Refractive index* nC' | 1.5207 |

| Refractive index* nC | 1.5203 |

| Abbe value νe | 58.3 ± 0.6 |

| Photoelastic constant in (nm/cm)/Mpa | 27.5 |

2. Thermal properties

| General thermal properties | Unit | Value |

|---|---|---|

| Mean specific heat capacity cp | in J/(g·K) (20 °C ; 100 °C) | 0.8 |

| Transformation temperature Tg | in °C | 542 |

"Coefficient of thermal Expansion (CTE) α in 10-6·K-1 (static measurement)"

| Degree | Value |

|---|---|

| (20 °C; 300 °C) | 9.4 |

| (20 °C; 200 °C) | 9.0 |

| (20 °C; 100 °C) | 8.6 |

"Coefficient of thermal Expansion (CTE) α in 10-6·K-1 (dynamic measurement)"

| Degree | Value |

|---|---|

| (20 °C; 100 °C) | 8.6 |

| (20 °C; 150 °C) | 8.8 |

| (20 °C; 200 °C) | 9.0 |

| (20 °C; 250 °C) | 9.2 |

| (20 °C; 300 °C) | 9.4 |

| (20 °C; 350 °C) | 9.6 |

| (20 °C; 400 °C) | 9.7 |

| (20 °C; 450 °C) | 9.9 |

| Viscosities | Viscosity lg ŋ in dPas | Temperature in °C |

|---|---|---|

| Strain point | 14.5 | 507 |

| Annealing point | 13.0 | 535 |

| Softening point | 7.6 | 711 |

Fuseability:

Fusing with SCHOTT ARTISTA® glasstypes using an adapted temperature / time programme results in a technically stressfree compound with a maximum stress birefringence of 70 nm/cm.

3. Mechanical properties

| Mechanical Properties |

Unit | Value |

|---|---|---|

| Density ρ | in g/cm³ | 2.56 |

| Young's modulus E | in kN/mm² | 71.1 |

| Poisson's ratio µ | 0.22 | |

| Torsion modulus G | in kN/mm² | 29 |

| Knoop hardness | HK 0.1/20 | 500 |

| Vickers hardness | HV 0.2/25 | 510 |

Chemical toughening (for thickness = 2.0 mm)

| Unit |

Value |

|---|---|

| Temperature ϑ in °C | 410 |

| Time t in h | 4 |

| Compressive stress (CS) in MPa | 441 |

| Depth of layer (DoL) in µm | 11 |

Thermal Toughening

Thermal toughening of B 270® is possible

4. Chemical properties

| Hydrolytic resistance (acc. to DIN ISO 719) | Value |

|---|---|

| Class | HGB 3 |

| Equivalent of alkali per gram glass grains in µg/g | 136 |

| Acid resistance (acc. to DIN 12116) | Value |

|---|---|

| Class | S 2 |

| Half surface weight loss after 6 hours in mg/dm² | 0.7 |

| Alkali resistance (acc. to DIN ISO 695) | Value |

|---|---|

| Class | A 1 |

| Surface weight loss after 3 hours in mg/dm² | 71 |

5. Electrical properties

| Dielectric constant εr (at ϑ = 25 °C) | Value |

|---|---|

| at 1 MHz | 7.5 |

| at 1 GHz | 6.7 |

| at 2 GHz | 6.8 |

| at 5 GHz | 6.7 |

| at 24 GHz | 6.6 |

| Dissipation factor tan δ (at ϑ = 25 °C) |

Value |

|---|---|

| at 1 MHz | 32 · 10-4 |

| at 1 GHz | 59 · 10-4 |

| at 2 GHz | 66 · 10-4 |

| at 5 GHz | 84 · 10-4 |

| at 24 GHz | 150 · 10-4 |

| Electric volume resistivity ρD in Ω·cm (at 50 Hz) |

|---|

| 6.1 · 107 ( ϑ = 250 °C) |

| 1.6 · 106 (ϑ = 350 °C) |

6. Transmittance values

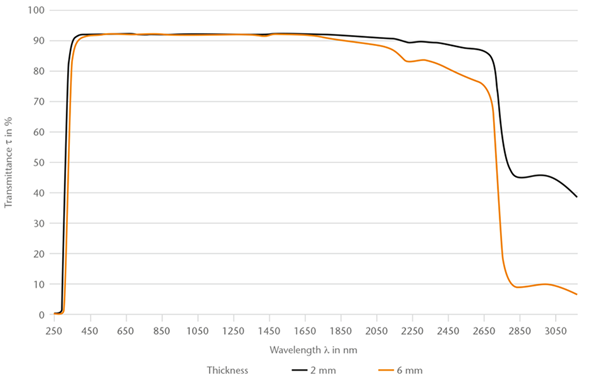

Spectral transmittance 250 - 3200 nm

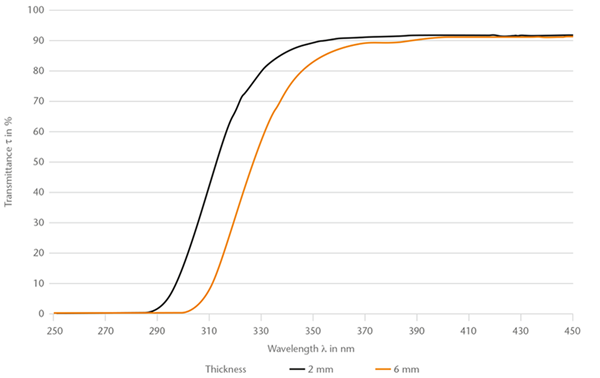

Spectral transmittance 250 - 450 nm

| Wavelength in nm at thickness 2.0 mm: | τ (λ) in % |

|---|---|

| 254 | < 0.1 |

| 380 | 90.8 |

| 632.8 | 91.9 |

| 1064 | 91.8 |

| Edge wavelength at 2 mm thickness | Wavelength in nm |

|---|---|

| λc (τ = 0.46) | 310 |

| λS ( τ = 0.05) | 293 |

| λP ( τ = 0.85) | 338 |

| Solarization* after UV-radiation at 2 mm thickness | Δ λc in nm |

|---|---|

| Shifting of the UV edge wavelength λc (τ = 0.46) in the direction of longer wavelength | < 2 |

*Measuring and Test Procedures

The sample will be irradiated with a UV - F 400 flood lamp.

The irradiation time amounts to 7h; the distance between flood lamp and sample fastening is 14 cm.

| Luminous transmittance at thickness in mm | τvD65 in % | τvA in % |

|---|---|---|

| 2.0 | 91.7 | 91.7 |

| UV - transmittance at thickness in mm | τUVA in % | τUVB in % |

|---|---|---|

| 2.0 | 84 | 19 |

| IR – transmittance at thickness in mm | τA in % |

|---|---|

| 2.0 | 91.9 |

| Solar direct transmittance at thickness | τe in % |

|---|---|

| 2.0 | 91.6 |

7. Colorimetry

| Chromaticity coordinates* at thickness 2.0 mm | Value |

|---|---|

| D65 | x = 0.313 |

| D65 | y = 0.329 |

| A | x = 0.448 |

| A | y = 0.408 |

| General color rendering index Ra at thickness in mm | Value |

|---|---|

| 2.0 | 100 |

* Chromaticity coordinates (color locus) are referred to the named Standard Illuminant according to CIE (2°-Observer)

Material properties of B 270® Thin

1. Optical

| Optical properties | Value |

|---|---|

| Refractive index* ng | 1.5341 |

| Refractive index* nF' | 1.5297 |

| Refractive index* nF | 1.5292 |

| Refractive index* ne | 1.5251 ± 0.001 |

| Refractive index* nd | 1.5230 |

| Refractive index* nD | 1.5229 |

| Refractive index* nC' | 1.5207 |

| Refractive index* nC | 1.5203 |

| Abbe valueνe | 58.3 ± 0.6 |

| Photoelastic constant in (nm/cm)/Mpa | 28.6 |

* Refractive indices:

Pretreatment of samples. Condition as supplied ["as drawn"]

2. Thermal

| General thermal properties | Unit | Value |

|---|---|---|

| CTE (Coefficient of thermal expansion) α | 10-6·K-1 (20 °C; 300 °C) | 9.4 |

| Mean specific heat capacity cp | in J/(g·K) (20 °C ; 100 °C) | 0.8 |

| Transformation temperature Tg | in °C | 536 |

| Viscosities | Viscosity lg ŋ in dPas | Temperature in °C |

|---|---|---|

| Strain point | 14.5 | 505 |

| Annealing point | 13.0 | 535 |

| Softening point | 7.6 | 723 |

3. Mechanical

| Mechanical properties |

Unit | Value |

|---|---|---|

| Densityρ | in g/cm³ | 2.56 |

| Young's modulus E | in kN/mm² | 69.8 |

| Poisson's ratio µ | 0.25 | |

| Torsion modulus G | in kN/mm² | 28 |

| Knoop hardness | HK 0.1/20 | 480 |

| Vickers hardness | HV 0.2/25 | 520 |

Chemical toughening (for thickness = 0.3 mm)

| Unit | Value |

|---|---|

| Temperatureϑin °C | 410 |

| Time t in h | 4 |

| Compressive stress (CS) in MPa | 331 |

| Depth of layer (DoL) in µm | 16 |

4. Chemical

| Hydrolytic resistance (acc. to DIN ISO 719) | Value |

|---|---|

| Class | HGB 3 |

| Equivalent of alkali per gram glass grains in µg/g | 170 |

| Acid resistance (acc. to DIN 12116) | Value |

|---|---|

| Class | S 2 |

| Half surface weight loss after 6 hours in mg/dm² | 1.0 |

| Alkali resistance (acc. to DIN ISO 695) | Value |

|---|---|

| Class | A 2 |

| Surface weight loss after 3 hours in mg/dm² | 80 |

5. Electrical

| Dielectric constant εr (at ϑ= 25 °C) | Value |

|---|---|

| at 1 MHz | 7.2 |

| at 1 GHz | 6.8 |

| at 2 GHz |

6.8 |

| at 5 GHz | 6.7 |

| at 24 GHz |

6.8 |

| at 77 GHz | 6.5 |

| Dissipation factor tanδ (atϑ= 25 °C) |

Value |

|---|---|

| at 1 MHz | 32 · 10-4 |

| at 1 GHz | 59 · 10-4 |

| at 2 GHz |

66 · 10-4 |

| at 5 GHz | 84 · 10-4 |

| at 24 GHz | 150 · 10-4 |

| at 77 GHz | 230 · 10-4 |

| Conductivity σ in S/cm for direct current | Value |

|---|---|

| at 25 °C | 5 · 10-16 |

| at 250 °C | 4 · 10-9 |

| at 350 °C | 2 · 10-7 |

| Electric volume resistivity ρD in Ω·cm for alternating current 50 Hz | Value |

|---|---|

| at 25 °C | 8.6 · 1011 |

| at 250 °C | 2.4 · 108 |

| at 350 °C | 5.8 · 106 |

| Temperature tk 100 in °C | Value |

|---|---|

| at 108 Ω · cm | 272 |

6. Transmittance values

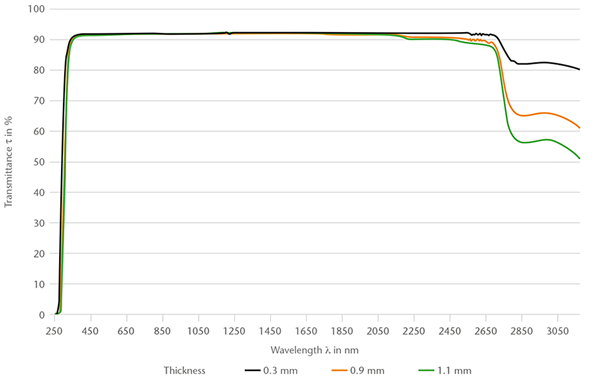

Spectral transmittance 250 - 3050 nm

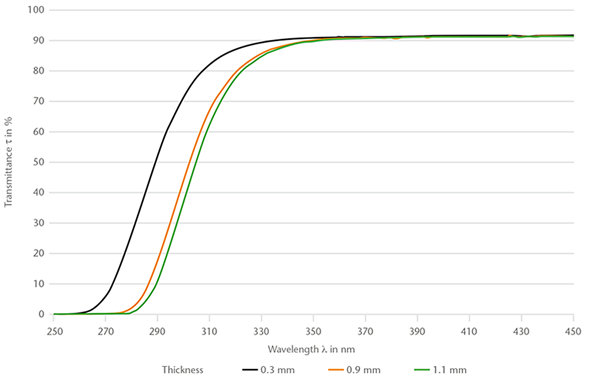

Spectral Transmittance: 250 - 450 nm

| Wavelength in nm at thickness 0.3 mm: | τ(λ) in % |

|---|---|

| 254 | < 0.1 |

| 380 | 91.3 |

| 632.8 | 92.0 |

| 1064 | 92.2 |

| Edge wavelength λc (τ = 0.46) at thickness in mm | Wavelength in nm |

|---|---|

| 0.3 | 287 |

| 0.9 | 299 |

| Luminous transmittance at thickness in mm | τvD65 in % | τvA in % |

|---|---|---|

| 0.3 | 91.9 | 91.9 |

| 0.9 | 91.6 | 91.7 |

B 270® products

SCHOTT B 270® is available as:

- Sheets

- Cut-to-size substrates

- Polished substrates and wafers

SCHOTT B 270® Thin is available as:

- Cut-to-size substrates

- Unpolished substrates and wafers

To find out more, please see the related products on the overview page.