D 263®

Outstanding and versatile technical properties

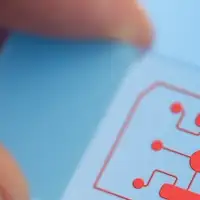

SCHOTT D 263® offers a large number of technical advantages. These include an excellent surface quality with low roughness, which eliminates the need for further polishing, and tight geometrical tolerances in a wide range of thicknesses. The exceptional luminous transmittance, low autofluorescence and high chemical resistance of D 263® all add to an impressive reputation as a durable and long-lasting performer.