Augmented Reality waveguides: 3D-Micromac and SCHOTT join forces

07 December 2022, Mainz, Germany

- 3D-Micromac has entered into a joint-development partnership (JDP) with SCHOTT.

- The JDP targets the development of a dedicated laser cutting process for SCHOTT RealView® glass wafers that increases glass edge strength for improved production yields.

- Another development task: a high-volume-manufacturing-capable laser micromachining tool that can achieve a throughput of nearly 600 AR eyepieces per hour.

According to Matthias Jotz, Head of Product Management for Augmented Reality at SCHOTT, “High refractive index glass is a key component for achieving optimum field of view and first-class image quality for AR headsets, providing the ultimate user experience. To scale up manufacturing on our patented SCHOTT RealView® high refractive index glass products, it is critical that we partner with the right equipment suppliers that can support our manufacturing goals with enabling process solutions. SCHOTT has worked with 3D-Micromac over many years, and their expertise in laser micromachining make them an ideal partner for developing a dedicated laser cutting technology for our augmented reality products.”

“3D-Micromac has been offering innovative laser machining solutions for the AR device market for several years, and this strategic partnership with SCHOTT, one of the foremost leaders in specialty glass, will further position us as a leading solutions provider for this high-growth-potential market,” stated Uwe Wagner, CEO of 3D-Micromac. “We believe that SCHOTT’s strong know-how and expertise in glass processing and material science, coupled with our leadership in laser micromachining, will enable us to develop new process solutions that can improve the bending strength of high refractive index glass to optimize yields while reducing production costs.”

For more information on 3D-Micromac’s innovative laser processes for the display and smart glass market, visit:

https://3d-micromac.com/laser-micromachining/markets/#glass-and-display-industry.

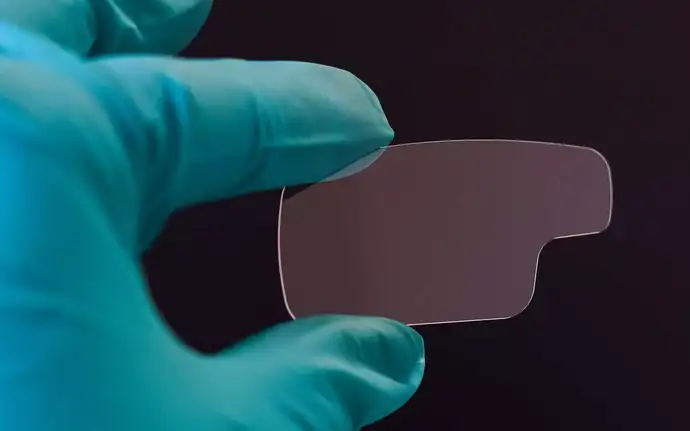

Layout of SCHOTT RealView® eyepieces on a high refractive index wafer following laser cutting with a 3D-Micromac laser micromachining system. Image source: 3D-Micromac.

Accordion Group

Founded in 2002, 3D-Micromac AG is the industry leader in laser micromachining, delivering powerful, user-friendly and leading-edge processes with superior production efficiency. We develop processes, machines and turnkey solutions at the highest technical and technological level. 3D-Micromac systems and services have been successfully implemented in various high-tech industries worldwide including photovoltaic, semiconductor, glass and display industries, micro diagnostics, and medical technology. For more information, visit the company’s website at http://www.3d-micromac.com.

Company Contact:

Mandy Gebhardt

Team Leader Marketing and Public Relations

3D-Micromac AG

Tel: +49 371 40043-26

E-Mail: gebhardt@3d-micromac.com

Agency Contact:

David Moreno

Principal

Open Sky Communications

Tel: +1.415.519.3915

E-Mail: dmoreno@openskypr.com

Pioneering – responsibly – together

These attributes characterize SCHOTT as a manufacturer of high-tech materials based on specialty glass. Founder Otto Schott is considered its inventor and became the pioneer of an entire industry.Always opening up new markets and applications with a pioneering spirit and passion – this is what has driven the #glasslovers at SCHOTT for more than 130 years. Represented in 34 countries, the company is a highly skilled partner for high-tech industries: Healthcare, Home Appliances & Living, Consumer Electronics, Semiconductors & Datacom, Optics, Industry & Energy, Automotive, Astronomy & Aerospace. In the fiscal year 2021, its 17,300 employees generated sales of 2.5 billion euros. SCHOTT AG is owned by the Carl Zeiss Foundation, one of the oldest foundations in Germany. It uses the Group's dividends to promote science. As a foundation company, SCHOTT has anchored responsibility for employees, society and the environment deeply in its DNA. The goal is to become a climate-neutral company by 2030.

Michael Müller

Head of Corporate Communications