Pneumatic conveying systems

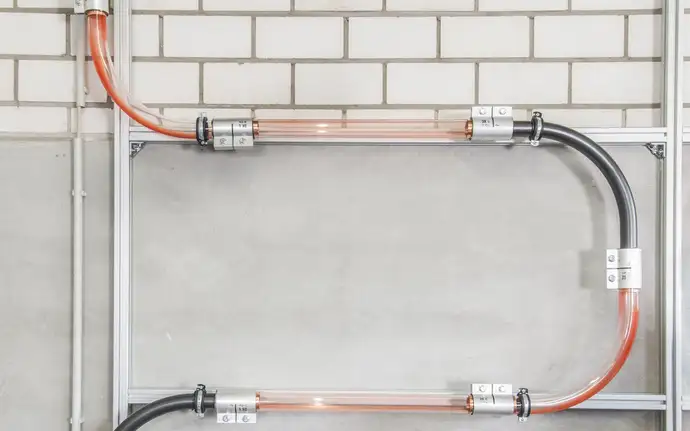

Modern pneumatic conveying systems perform larger and more complex tasks than ever, but the physical demands placed on the tubes, bends and elbows remain the same. A rapid flow of materials can destroy tubing – the more abrasive the material, the quicker the tubes wear out. As the tubes wear out, tiny particles will enter the system and contaminate the final product. This is especially dangerous when the transported material is food, pharmaceuticals, or an insulator. To avoid deterioration and contamination, it’s vital that the tubes and bends are made from neutral and resilient materials, with strong mechanical durability and low abrasion.

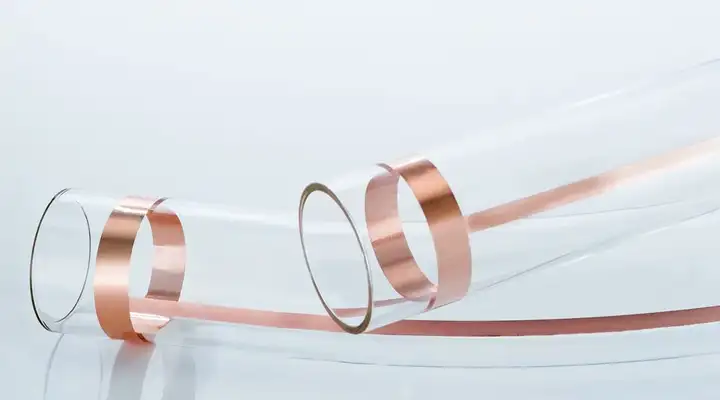

SCHOTT manufactures a wide range of glass tubes, bends and elbows specifically designed for pneumatic conveying systems. Made using the highly durable DURAN® glass tubing, our bends offer extreme hardness for the transportation of extremely abrasive materials, with a lifespan 10 times longer than that of stainless steel.

The transparency of glass also offers the advantage of simple monitoring of the material flowing through the system, with special suitability for the food industry thanks to its low abrasion and high food grade properties. For reliable electrostatic discharge, it’s recommended that all tubing is fitted with copper conductive tape.