Product Variants of Optical Components

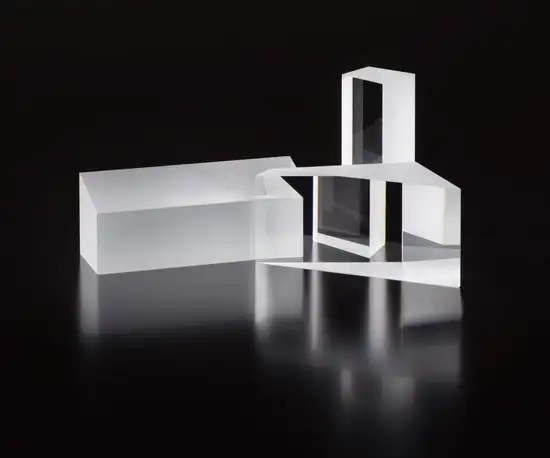

Prisms

CHARACTERISTICS

Offering excellent thermal stability, prisms using total internal reflection avoid loss of light in the optical path. SCHOTT also manufactures prisms using non-standard glasses, which results in even higher standards of homogeneity (up to H4 level). Whether right-angle, rhomboid, roof or penta, SCHOTT prisms can stretch the boundaries of design for a vast range of applications.

YOUR ADVANTAGES

- SCHOTT offers prisms at various processing stages: milled, polished, coated, cemented or assembled.

- The most appropriate processing method (CNC or pressing) is selected depending on the quantity, size and type of glass.

- Extensive expertise in cementing.

- Flexible production process – from a single piece to serial production.

- All prisms can be coated to specific custom designs to serve your chosen application.

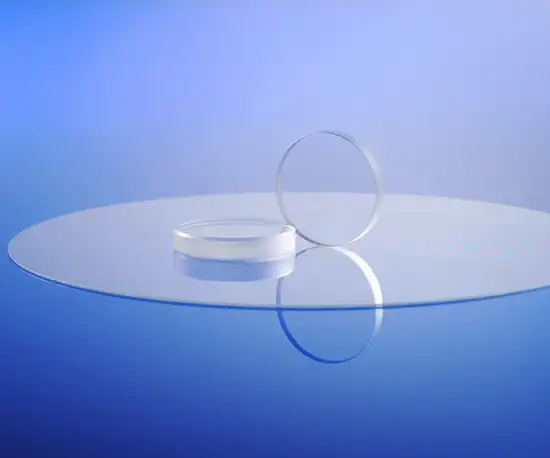

High precision aspheres

CHARACTERISTICS

Aspherical lenses are increasingly used to replace multi-spherical element assemblies, resulting in more lightweight and compact designs. Aspheres are found in a growing number of digital projection, camera and cine lens systems, as well as high power laser systems, medical apparatus and satellites. The ultra-smooth surfaces, combined with a range of different materials and advanced coatings, can open up new opportunities for many industries.

ADVANTAGES

- Suitable for demanding, high performance applications.

- Customized products.

- Single piece to serial production capability.

- SCHOTT masters the entire value chain, from raw glass to final product.

- All aspheres can be coated to specific designs to suit your chosen application.

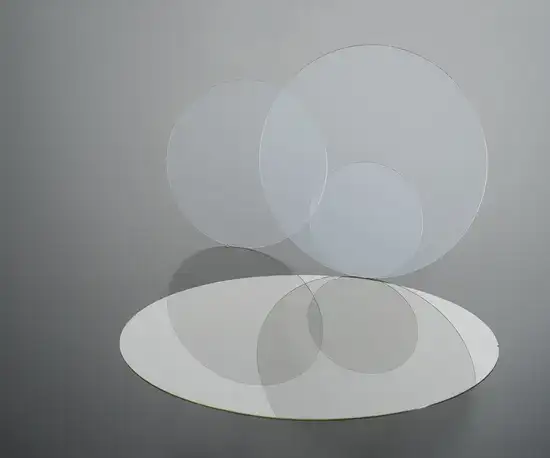

Spherical lenses

CHARACTERISTICS

SCHOTT spherical lenses are available as singlets, doublets and triplets in a variety of shapes, and we are always happy to customize products for individual customer needs. We use all types of optical glass materials upon request, including fused silica, with SCHOTT’s expansive range of coatings widening the choice of options.

Spherical lenses also function as part of lens systems performing an achromatic function, with multiple elements working together to limit chromatic and spherical aberrations and bring separate wavelengths into focus on the same plane.

YOUR ADVANTAGES

- SCHOTT masters the entire value chain and can leverage its renowned product portfolio to produce customized spherical lenses.

- Singlet, doublet, and triplet spherical lenses available in different processing stages, including matt, polished, coated, and cemented.

- Customized coatings available to suit your application.

Rod lenses

CHARACTERISTICS

SCHOTT rod lenses are made from eco-friendly, MDR- and RoHS-compliant materials, including N-SSK20. The combination of high transmission glasses and optimized coatings enable maximum resolution and contrast, even at weak signal levels. They deliver excellent performance in the blue spectral range, maintain consistent optical properties across production batches, and withstand demanding chemical environments. Manufactured with tight tolerances, supported by automated quality inspection, and embedded in established high-volume series production, they guarantee reliable precision for endoscopic imaging. Customized specifications are available on request.

YOUR ADVANTAGES

-

Seamless supply chain from raw glass to finished rod lenses.

-

Established high-volume series production.

-

Proven R&D and quality leadership in endoscopic optics.

-

100% automated quality control for a reliable and constant quality for mass production.

-

Rapid prototyping and design-to-manufacture support.

-

Optimized coatings tailored to your application.

Plano optics

CHARACTERISTICS

Glass substrates are components manufactured from materials ranging from optical and technical glasses to fused silica, sapphire and other crystals. They are polished to a tight specification and serve as the base for coatings in optical systems such as beam splitters and interference filters, reflecting or transmitting light according to precise specifications.

Windows are transparent or coated components, mostly plano-plano parallel polished, which facilitate exceptional performance in optical and imaging systems. The tight tolerances and low CTE offered by SCHOTT components ensure optimum results regardless of application.

YOUR ADVANTAGES

- SCHOTT masters the entire value chain and can leverage its renowned product portfolio to produce windows and substrates closely tailored to your requirements.

- Flexible production process – from a single piece to serial production.

- Extensive expertise in gluing, cementing and sub-assembling to integrate substrates and windows into custom-designed hardware.

- Customized coatings available on request, along with double- or single-sided polishing.

Optical glass wafers

CHARACTERISTICS

The technical specifications of SCHOTT optical glass wafers depend on your requirements as a customer, enabling you to find the right combination of characteristics that suits your application. We can achieve highly impressive specifications in terms of refractive index, Abbe number, transmittance and coefficient of thermal expansion (CTE), and we can work with you to develop the right combination of qualities. Typical applications for wafer-level optics include optical sensors, micro-optics and camera optics, nanoimprint lithography (NIL), and advanced metrology.

YOUR ADVANTAGES

- High volume production of wafers in diameters of 150-300 mm.

- Excellent surface roughness of <1 nm.

- Outstanding total thickness variation (TTV) of <1 µm.

- Wide range of material families available: optical glasses, technical glasses, fused silica, filter glasses, glass-ceramics and sapphire.

-

A variety of melting and processing techniques enable us to supply large volumes of high precision wafers tailored to your needs.