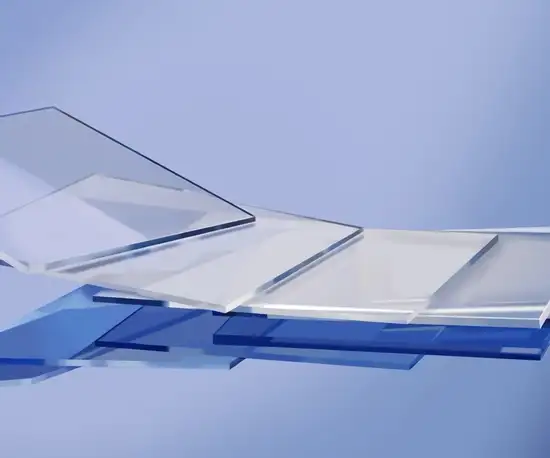

Product Variants of Sheets

Down-drawn sheets

CHARACTERISTICS

The down-draw process produces thin and ultra-clear flat glasses. The process involves a ribbon of molten glass being pulled down from above before moving across various drums and through a cooling track. This results in a pristine surface that can accommodate processes such as coating, bonding and etching, with very tight thickness tolerances of ± 10µm, and a TTV < 10µm.

YOUR ADVANTAGES

- Extremely flat and smooth surface on both sides.

- Very low bulk and cosmetic defects.

- Wide thickness from direct hot forming, without the need for polishing or thinning.

- Very tight thickness tolerances to accommodate different processing methods.

- Outstanding chemical strengthening performance.

Up-drawn sheets

CHARACTERISTICS

The groundbreaking up-draw process was perfected by SCHOTT to manufacture thin and ultra-clear flat glasses. The technique involves a ribbon of molten glass being pulled up across various drums and then through a cooling track, resulting in a fire-polished surface with an outstanding surface roughness of < 0.5nm. With a thickness spectrum ranging from 0.9 mm to 10 mm, this process can be used to create supremely clear ‘ultra-white’ glass sheets.

YOUR ADVANTAGES

- Pristine fire-polished surface on both sides, with no need for further polishing.

- Defined initial thickness resulting in minimal material loss during processing.

- Enables high quality production of unique glass materials unsuited to float processing.

Floated sheets

CHARACTERISTICS

Floated glass sheets such as SCHOTT’s renowned BOROFLOAT® are created using a sophisticated process in which a continuous strip of molten glass is guided over a bath of molten tin. The glass ‘floats’ over the tin and cools to form a very flat surface on both sides of the glass, with the top fire-polished due to the effect of hot gases. The resulting sheets have a very high chemical stability, outstanding thermal resistance and strong transparency, while being mechanically robust and resistant to scratching and abrasion. The hot forming process also enables a broad thickness range.

YOUR ADVANTAGES

- Outstanding transparency and optical qualities.

- Very high thermal shock resistance, so suitable for tough environments.

- Excellent mechanical strength and resistance to damage.

- Highly homogenous material ensuring reliable performance.

- Available in a wide range of thicknesses.