Technical Details of Infrared Glasses and Materials

Key qualities of Infrared Glasses and Materials

SCHOTT Infrared Chalcogenide Glass

Forms of Supply

We offer infrared chalcogenide glasses up to 95 mm in diameter and thicknesses up to 150 mm. Typical forms of supply will depend on customer's requirements.

Our polished blanks for sample parts are offered up to 95 mm in diameter and thicknesses up to 30 mm.

Material Properties IRG 22 – IRG 27

| Material Properties | IRG 22 | IRG 24 | IRG 25 | IRG 26 | IRG 27 |

|---|---|---|---|---|---|

| Composition | Ge33As12Se55 | Ge10As40Se50 | Ge28Sb12Se60 | As40Se60 | As2S3 |

| Germanium free | Germanium free | ||||

| Density | 4.41 g/cm3 | 4.47 g/cm3 | 4.66 g/cm3 | 4.63 g/cm3 | 3.20 g/cm3 |

| Thermal expansion (20 – 100°C) |

12.5 · 10–6/K | 20.0 · 10–6/K | 14.0 · 10–6/K | 21.4 · 10–6/K | 22.5 · 10–6/K |

| Transition temperature | 368 °C | 225 °C | 285 °C | 185 °C | 197 °C |

| Thermal change dn/dT* |

94.8 · 10–6/K (1 μm) |

46.0 · 10–6/K (1 μm) |

79.2 · 10–6/K (1 μm) |

76.2 · 10–6/K (1 μm) |

15.6 · 10–6/K (1 μm) |

| 67.7 · 10–6/K (5 μm) |

21.15 · 10–6/K (5 μm) |

62.0 · 10–6/K (5 μm) |

33.4 · 10–6/K (5 μm) |

-3.2 · 10–6/K (5 μm) |

|

| 67.1 · 10–6/K (10 μm) |

20.3 · 10–6/K (10 μm) |

61.1 · 10–6/K (10 μm) |

32.2 · 10–6/K (10.6 μm) |

-3.7 · 10–6/K (10.6 μm) |

|

| Refractive index |

2.5971 (1 μm) | 2.7249 (1 μm) | 2.7284 (1 μm) | 2.9316 (1 μm) | 2.4841 (1 μm) |

| 2.5104 (5 μm) | 2.6192 (5 μm) | 2.6183 (5 μm) | 2.7909 (5 μm) | 2.4129 (5 μm) | |

| 2.4968 (10 μm) | 2.6090 (10 μm) | 2.6030 (10 μm) | 2.7781 (10 μm) | 2.3842 (10 μm) |

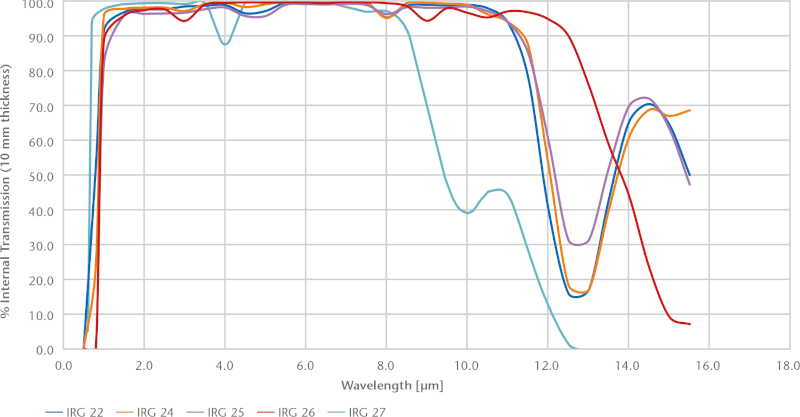

Transmission of Infrared Glass IRG 22 – IRG 27 (10 mm thickness)

IR Transmission

Sapphire

Material Properties

- Extreme hardness and high mechanical strength

- Excellent thermal conductivity and heat resistance

- High transmittance (UV to IR)

- Low dn/dT

- High electrical resistance (1,014 Ohm-cm)

- High dielectric constant (9.39 from 1.0 MHz to 8.5 GHz)

Specifications

| Attribute | Commercial Quality | Precision Quality | Ultra-Precision Quality |

|---|---|---|---|

| Size (round and square) | Ø from 10 to 300 mm from 10 to 210 mm |

||

| Size tolerance1 | ± 0.2 mm | ± 0.10 mm | ± 0.05 mm |

| Thickness1 | From 1 to 40 mm | ||

| Thickness tolerance1 | ± 0.2 mm | ± 0.10 mm | ± 0.05 mm |

| Parallelism1 | < 5 arc minutes | < 1 arc minute | < 30 arc seconds |

| Surface accuracy (PV)1 | 5 λ (546 nm) | λ/2 (546 nm) | λ/10 (546 nm) |

| Surface quality (scratch & dig) | According to MIL 80 - 50 | According to MIL 40 - 20 | According to MIL 20 – 10 |

| Surface roughness (Rq) | < 10 nm | < 3 nm | < 1 nm |

| AR coating | Custom-designed | ||

| Order quantity | Depending on customer specifications. Please contact us. | ||

| Delivery time (weeks) | 6 - 10 weeks, assuming raw materials are available. | ||

1 Depends on the geometry

| Mechanical Properties2 | ||

|---|---|---|

| Tensile strength | 40,000 – 60,000 psi (design criterion) | 0.27 – 0.41 GPa |

| Flexural strength | 70,000 –130,000 psi (design criterion) | 0.48 – 0.89 GPa |

| Young’s modulus, E (25 °C) (modulus of elasticity) |

50 x 106psi | 345 GPa |

| Compressive modulus, K | 55 x 106psi | 379 GPa |

| Flexural modulus (modulus of rupture) |

52 x 106psi | 358 GPa |

| Shear modulus, G (modulus of rigidity) |

21.5 x 106psi | 148 GPa |

| Bulk modulus, k (volumetric modulus of elasticity) Poisson’s ratio |

35 x 106psi 0.29 |

241 GPa |

2 1 psi = 6.9 kPa

| Supply Forms | Thicknesses | Dimensions |

|---|---|---|

Customized processing

|

from 1 mm to 40 mm | Ø from 10 to 300 mm from 10 to 210 mm |

| Plano surface Spherical surface |

||

| Various shapes from round to square |

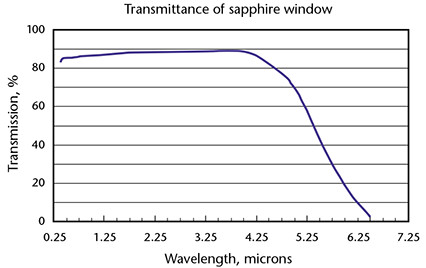

Transmission Curve