Technical Details of D 263®

Outstanding and adaptable technical advantages

Material Properties of D 263® M

1. Optical properties

| Optical Properties | Value |

|---|---|

| Refractive index* ng | 1.5354 |

| Refractive index* nF' | 1.5305 |

| Refractive index* nF | 1.5300 |

| Refractive index* ne | 1.5255 ± 0.0015 |

| Refractive index* nd | 1.5231 |

| Refractive index* nD | 1.5230 |

| Refractive index* nC' | 1.5209 |

| Refractive index* nC | 1.5204 |

| Abbe value νe | 55 |

| Photoelastic constant in (nm/cm)/Mpa | 34.7 |

* Refractive indices: Pretreatment of samples.

Condition as supplied ["as drawn"]

2. Thermal properties

| General thermal properties | Unit | Value |

|---|---|---|

| CTE (Coefficient of thermal expansion) α | 10-6·K-1 (20 °C; 300 °C) | 7.2 |

| Mean specific heat capacity cp | in J/(g·K) (20 °C; 100 °C) | 0.8 |

| Transformation temperature Tg | in °C | 557 |

| Viscosities | Viscosity lg ŋ in dPas | Temperature in °C |

|---|---|---|

| Strain point | 14.5 | 529 |

| Annealing point | 13.0 | 557 |

| Softening point | 7.6 | 736 |

3. Mechanical properties

| Mechanical Properties |

Unit | Value |

|---|---|---|

| Density ρ | in g/cm³ | 2.51 |

| Young's modulus E | in kN/mm² | 72.9 |

| Poisson's ratio µ | 0.21 | |

| Torsion modulus G | in kN/mm² | 30 |

| Knoop hardness | HK 0.1/20 | 470 |

| Vickers hardness | HV 0.2/25 | 510 |

Chemical toughening (for thickness = 0.145 mm)

| Unit |

Value |

|---|---|

| Temperature ϑ in °C | 390 |

| Time t in h | 4 |

| Compressive stress (CS) in MPa | 290 |

| Depth of layer (DoL) in µm | 15 |

4. Chemical properties

| Hydrolytic resistance (acc. to DIN ISO 719) | Value |

|---|---|

| Class | HGB 1 |

| Equivalent of alkali per gram glass grains in µg/g | 20 |

| Acid resistance (acc. to DIN 12116) | Value |

|---|---|

| Class | S3 |

| Half surface weight loss after 6 hours in mg/dm² | 2.1 |

| Alkali resistance (acc. to DIN ISO 695) | Value |

|---|---|

| Class | A 2 |

| Surface weight loss after 3 hours in mg/dm² | 88 |

5. Electrical properties

| Dielectric constant εr (at ϑ = 25 °C) | Value |

|---|---|

| at 1 MHz | 6.7 |

| at 1 GHz | 6.4 |

| at 5 GHz | 6.3 |

| Dissipation factor tan δ (at ϑ = 25 °C) |

Value |

|---|---|

| at 1 MHz | 61·10-4 |

| at 1 GHz | 74·10-4 |

| at 5 GHz | 101·10-4 |

| Electric volume resistivity ρD (for alternate current 50 Hz ) |

|---|

| 1.6·108 ( ϑ = 250 °C) |

| 3.5·106 (ϑ = 350 °C) |

6. Transmittance values

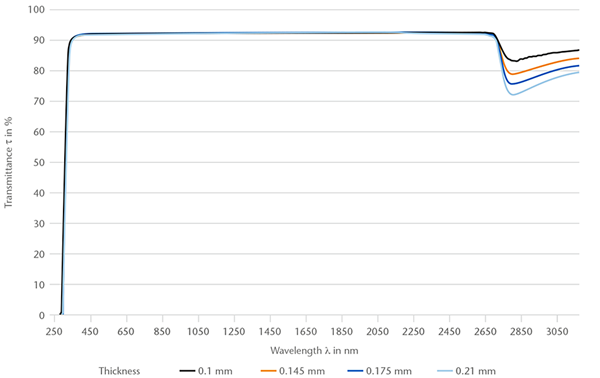

Spectral transmittance: 250 - 3150 nm

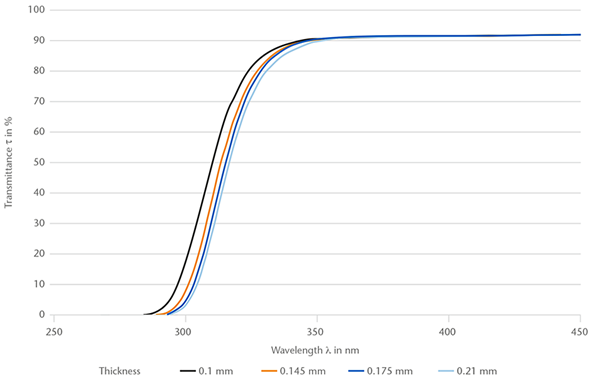

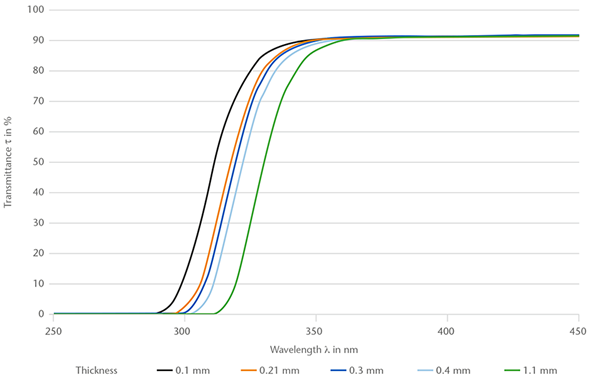

Spectral transmittance: 250 - 450 nm

| Wavelength in nm at thickness 0.145 mm: | τ (λ) in % |

|---|---|

| 254 | < 0.1 |

| 380 | 91.2 |

| 632.8 | 91.9 |

| 1064 | 92.2 |

| Edge wavelength λc (τ = 0.46) at thickness in mm | Wavelength in nm |

|---|---|

| 0.100 | 308 |

| 0.145 | 312 |

| 0.175 | 314 |

| 0.210 | 315 |

| Luminous transmittance at thickness in mm | τvD65in % |

|---|---|

| 0.145 | 91.7 ± 0.3 |

Material properties of D 263® bio

1. Optical properties

| Optical Properties | Value |

|---|---|

| Refractive index* ng | 1.5354 |

| Refractive index* nF' | 1.5305 |

| Refractive index* nF | 1.5300 |

| Refractive index* ne | 1.5255 ± 0.0015 |

| Refractive index* nd | 1.5231 |

| Refractive index* nD | 1.5230 |

| Refractive index* nC' | 1.5209 |

| Refractive index* nC | 1.5204 |

| Abbe value νe | 55 |

* Refractive indices: Pretreatment of samples.

Condition as supplied ["as drawn"]

2. Thermal properties

| General thermal properties | Unit | Value |

|---|---|---|

| CTE (Coefficient of thermal expansion) α | 10-6·K-1 (20 °C; 300 °C) | 7.2 |

| Mean specific heat capacity cp | in J/(g·K)(20 °C; 100 °C) | 0.8 |

| Transformation temperature Tg | in °C | 557 |

| Viscosities | Viscosity lg ŋ in dPas | Temperature in °C |

|---|---|---|

| Strain point | 14.5 | 529 |

| Annealing point | 13.0 | 557 |

| Softening point | 7.6 | 736 |

3. Mechanical properties

| Mechanical Properties |

Unit | Value |

|---|---|---|

| Density ρ | in g/cm³ | 2.51 |

| Stress optical coefficient C | 1.02·10-12 m²/N | 3.4 |

| Young's modulus E | in kN/mm² | 72.9 |

| Poisson's ratio µ | 0.21 | |

| Torsion modulus G | in kN/mm² | 30 |

| Knoop hardness | HK 0.1/20 | 470 |

| Vickers hardness | HV 0.2/25 | 510 |

Chemical toughening (for thickness = 0.3 mm)

| Unit |

Value |

|---|---|

| Temperature ϑ in °C | 410 |

| Time t in h | 4 |

| Compressive stress (CS) in MPa | 317 |

| Depth of layer (DoL) in µm | 18 |

4. Chemical properties

| Hydrolytic resistance (acc. to DIN ISO 719) | Value |

|---|---|

| Class | HGB 1 |

| Equivalent of alkali per gram glass grains in µg/g | 20 |

| Acid resistance (acc. to DIN 12116) | Value |

|---|---|

| Class | S 3 |

| Half surface weight loss after 6 hours in mg/dm² | 2.1 |

| Alkali resistance (acc. to DIN ISO 695) | Value |

|---|---|

| Class | A 2 |

| Surface weight loss after 3 hours in mg/dm² | 88 |

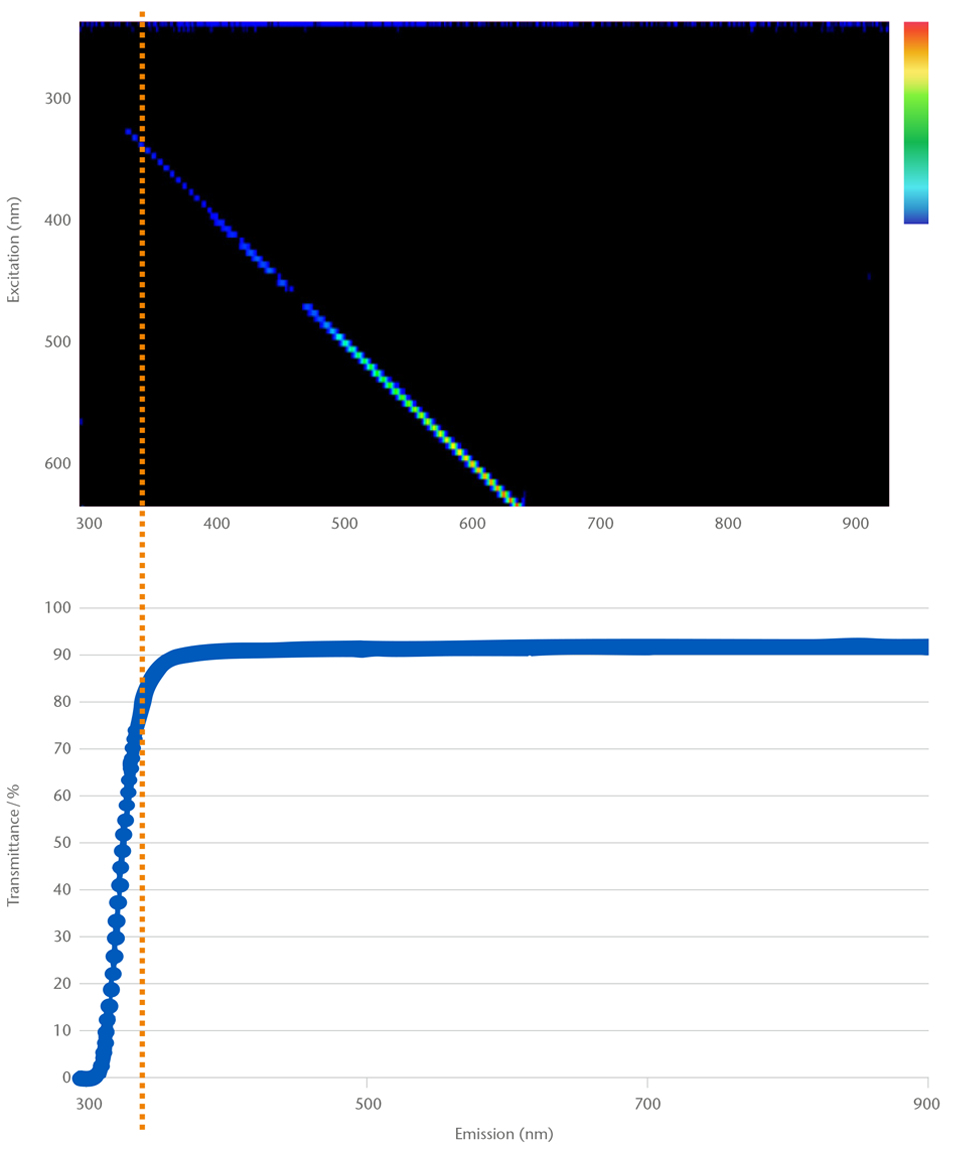

Auto fluorescence in >80% transmission spectrum

5. Electrical properties

| Dielectric constant εr (at ϑ = 25 °C) | Value |

|---|---|

| at 1 MHz | 6.7 |

| at 1 GHz | 6.4 |

| at 5 GHz | 6.3 |

| Dissipation factor tan δ (at ϑ = 25 °C) |

Value |

|---|---|

| at 1 MHz | 61·10-4 |

| at 1 GHz | 74·10-4 |

| at 5 GHz | 101·10-4 |

| Electric volume resistivity ρD in Ω·cm alternate current 50 Hz |

|---|

| 1.6·108 ( ϑ = 250 °C) |

| 3.5·106 (ϑ = 350 °C) |

6. Transmittance values

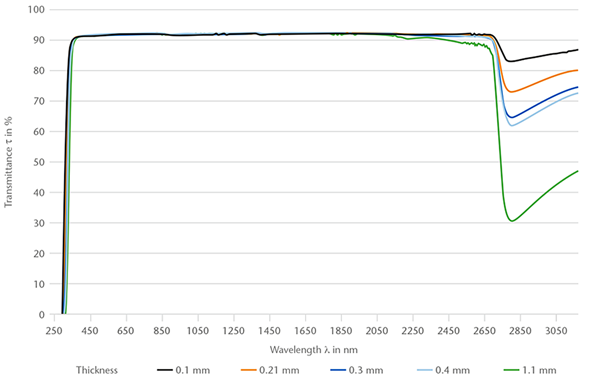

Spectral transmittance: 250 - 3150 nm

Spectral transmittance: 250 - 450 nm

| Wavelength in nm at thickness 0.3 mm: | τ (λ) in % |

|---|---|

| 254 | < 0.1 |

| 380 | 91.2 |

| 632.8 | 92 |

| 1064 | 92 |

| Edge wavelength λc (τ = 0.46) at thickness in mm | Wavelength in nm |

|---|---|

| 0.10 |

308 |

| 0.21 | 315 |

| 0.30 | 318 |

| 0.40 | 321 |

| 1.10 | 329 |

| Luminous transmittance at thickness in mm | τvD65in % |

|---|---|

| 0.3 | 91.7 ± 0.3 |

Material properties of D 263®T eco

1. Optical properties

| Optical Properties | Value |

|---|---|

| Refractive index* ng | 1.5354 |

| Refractive index* nF' | 1.5305 |

| Refractive index* nF | 1.5300 |

| Refractive index* ne | 1.5255 ± 0.0015 |

| Refractive index* nd | 1.5231 |

| Refractive index* nD | 1.5230 |

| Refractive index* nC' | 1.5209 |

| Refractive index* nC | 1.5204 |

| Abbe value νe | 55 |

| Photoelastic constant in (nm/cm)/Mpa | 34.7 |

* Refractive indices: Pretreatment of samples.

Condition as supplied ["as drawn"].

2. Thermal properties

| Thermal Properties - General | Unit | Value |

|---|---|---|

| CTE (Coefficient of thermal expansion) α | 10-6·K-1 (20 °C; 300 °C) | 7.2 |

| Mean specific heat capacity cp | J/(g·K) (20 °C to 100 °C) | 0.8 |

| Transformation temperature Tg | °C | 557 |

| Thermal Properties - Viscosities | Viscosity lg ŋ in dPas | Temperature in °C |

|---|---|---|

| Strain point | 14.5 | 529 |

| Annealing point | 13.0 | 557 |

| Softening point | 7.6 | 736 |

3. Mechanical properties

| Mechanical Properties |

Unit | Value |

|---|---|---|

| Density ρ | in g/cm³ | 2.51 |

| Young's modulus E | in kN/mm² | 72.9 |

| Poisson's ratio µ | 0.21 | |

| Torsion modulus G | in kN/mm² | 30 |

| Knoop hardness | HK 0.1/20 | 470 |

| Vickers hardness | HV 0.2/25 | 510 |

Chemical toughening (for thickness = 0.3 mm)

| Unit |

Value |

|---|---|

| Temperature ϑ in °C | 410 |

| Time t in h | 4 |

| Compressive stress (CS) in MPa | 320 |

| Depth of layer (DoL) in µm | 18 |

4. Chemical properties

| Hydrolytic resistance (acc. to DIN ISO 719) | Value |

|---|---|

| Class | HGB 1 |

| Equivalent of alkali per gram glass grains in µg/g | 20 |

| Acid resistance (acc. to DIN 12116) | Value |

|---|---|

| Class | S 2 |

| Half surface weight loss after 6 hours in mg/dm² | 1.4 |

| Alkali resistance (acc. to DIN ISO 695) | Value |

|---|---|

| Class | A 2 |

| Surface weight loss after 3 hours in mg/dm² | 88 |

5. Electrical properties

| Dielectric constant εr (at ϑ = 25 °C) | Value |

|---|---|

| at 1 MHz | 6.7 |

| at 1 GHz | 6.4 |

| at 5 GHz | 6.3 |

| Dissipation factor tan δ (at ϑ = 25 °C) |

Value |

|---|---|

| at 1 MHz | 61·10-4 |

| at 1 GHz | 74·10-4 |

| at 5 GHz | 101·10-4 |

| Electric volume resistivity ρD in Ω·cm (at 50 Hz) |

|---|

| 1.6·108 ( ϑ = 250 °C) |

| 3.5·106 (ϑ = 350 °C) |

6. Transmittance values

| Wavelength in nm at thickness 0.3 mm: | τ (λ) in % |

|---|---|

| 254 | < 0.1 |

| 380 | 91.2 |

| 632.8 | 92.0 |

| 1064 | 92.0 |

| Edge wavelength λc (τ = 0.46) at thickness in mm | Wavelength in nm |

|---|---|

| 0.10 | 308 |

| 0.21 | 315 |

| 0.30 | 318 |

| 0.40 | 321 |

| 1.10 | 329 |

| Luminous transmittance at thickness in mm | τvD65in % |

|---|---|

| 0.3 | 91.7 ± 0.3 |

D 263® products

SCHOTT D 263® is available as:

- Sheets

- Cut-to-size substrates

- Unpolished substrates and wafers

- FLEXINITY®

To find out more, please see the related products on the overview page.