Reliability in electronic packaging

What is hermetic sealing and when is it needed?

Hermetic seals are often used in applications where electronics or electronic systems need to reliably function despite high or low temperatures, high moisture levels, high pressure, or aggressive chemicals. They are also applied, when lifetime, safety or stable performance are of critical importance.

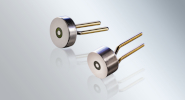

The seals prevent the intrusion or leakage of moisture or gases while simultaneously enabling electrical or optical signal transmission. For example, hermetic seals are used to package automotive electronics that need to function even when exposed to high temperature variations and driving vibrations and for medical device electronics that need to endure steam sterilization.

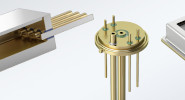

Hermetic seals can be created using hermetic glass-to-metal sealing, which combines metal and glass to accomplish vacuum-tight electrical connectors, packaging, feedthroughs, or optical windows/lenses in electronics or electronic systems. This approach can also be used for microelectronic packaging and power packages. Ceramic-to-metal as well as full ceramic packages can also be used to achieve hermeticity.

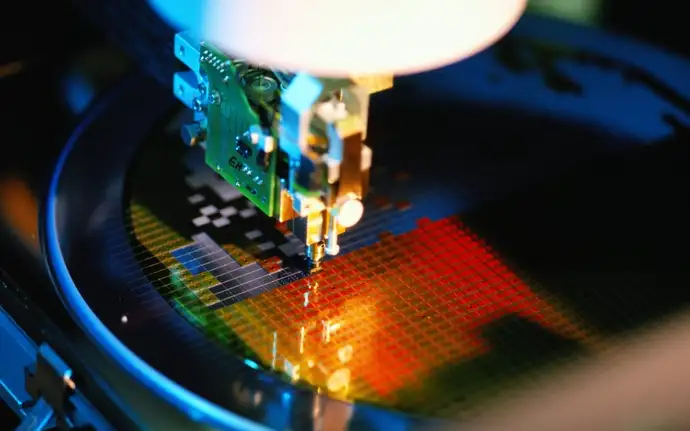

A novel technology called glass micro bonding is another option to form ultra-miniaturized hermetic packaging for highly sensitive electronics. It uses a laser-based wafer-scale process to manufacture packages for medical implants, aerospace applications or to package MEMS and micro-optics.

To learn more about hermetic packaging, please also refer to our article on when hermetic sealing is useful. You can also dive into a detailed definition of hermeticity, how is it tested, and what the difference between hermetic and quasi-hermetic packaging is.

What are the various protection grades of electronic chip and module packaging?

Electronic packaging can be accomplished on several levels ranging from the chip level, in which a semiconductor die is protected, to a full system that combines various devices. The protection level can also vary from little to no protection up to a full hermetic package that can be achieved using in-organic, non-aging materials using glass-to-metal, or ceramics.

Non-hermetic packaging materials and their protection levels:

|

Type |

Protection Level |

Description |

Usage / Applications |

|---|---|---|---|

|

Polymer films |

Low |

Used as protective coatings or encapsulation, thin film polymers provide a low level of protection against moisture and dust. |

Used primarily for electrical insulation. |

|

Potting compounds and encapsulants |

Low |

Epoxy, -, silicone, polyurethane, and acrylic can be used to seal or encapsulate electronic components and can provide moderate protection levels. |

Usually applied in a liquid or gel-like form and then hardened or cured. |

|

Polymer/ Plastic enclosures |

Low to moderate |

Limited defense against dust and short-term exposure to moisture. May not be suitable for extended environmental exposures. |

Commonly used for standard consumer electronics applications. |

|

Conformal thin film coatings |

Low to moderate |

Acrylic-, epoxy-, and silicone- parylene coatings offer reasonable protection against moisture, dust, and some chemicals. |

Applied as thin films over circuit boards. |

|

O-Rings or Gaskets |

Advanced |

Typically made of specialized rubbers (e.g. silicone, NBR, EPDM, PTFE), metal, or composite materials. Gaskets and O-rings provide a solid level of defense against moisture, gases, and contaminants. |

Wide range of applications, where sealing, fluid containment, and environmental protection are critical. |

Hermetic packaging materials and their protection levels:

|

Type |

Protection Level |

Description |

Usage / Applications |

|---|---|---|---|

|

High |

Metal feedthroughs, packages and other connections that use glass as the conductor insulation material offer excellent electrical insulation. By choosing glasses and metals with appropriate coefficients of thermal expansion, the materials can be tightly joined without using any additional interface materials, creating a durable and robust hermetic seal. |

Used in a broad range of electronic packaging applications and industrial settings with enhanced reliability or performance requirements. |

|

|

Ceramic-to-Metal Seals |

High |

The combination of ceramics and metal offers high thermal conductivity and mechanical durability properties. The hermetic bond between metal and ceramic materials is usually achieved using brazing or soldering. |

Common in aerospace, medical devices, and high-stress environments. |

|

Multilayer Ceramics

|

High |

Layered ceramic structures enable compact design and versatile electrical properties. Low-Temperature Co-Fired Ceramics (LTCC) are more often used for intricate designs, whereas High-Temperature Co-Fired Ceramics (HTCC) are well-suited for harsh environments. |

Used in integrated circuits, capacitors, and miniaturized electronic components. |

|

High |

A special room-temperature laser welding process for glass wafers, enabling the manufacture of miniature, chip-size all-glass packaging. |

Miniaturized packaging for medical implants, aerospace, MEMS, and micro-optics. |

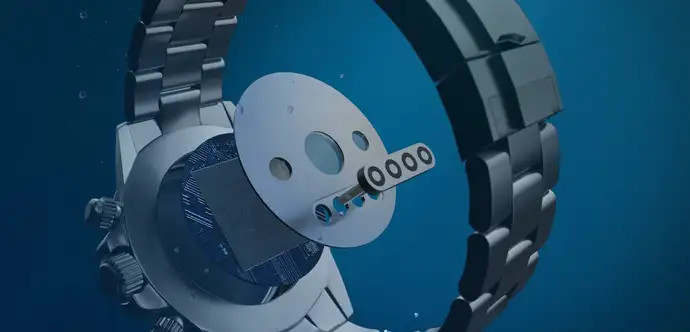

How can I achieve true waterproofness for an electronic device - above an IP68 protection rating?

The IP68 ingress protection (IP) rating indicates that a product or enclosure has a high level of protection against intrusion of solids and liquids. This includes dust and water and can thus be used in environments where particles or moisture are a concern. IP68-rated devices are commonly found in waterproof smartphones and other consumer electronics, industrial equipment, and outdoor applications. Although ratings higher than IP68 are not generally used, hermetic sealing is an option if higher levels of protection are needed.

Hermetic sealing creates an airtight and watertight seal, typically by welding or soldering the seams or joints of an enclosure, such as a metal or glass container. Hermetic sealing is often used when very high or virtually complete impermeability to gases and liquids is required or advantageous. This is often the case in certain medical devices, aerospace, or high-precision instruments or even wearable devices used for diving.

Advantages and disadvantages of hermetic sealing

- Hermeticity provides the highest level of protection against the intrusion of liquids, gases, dust, and more.

- Hermetic seals are typically used if even small amounts of gas or moisture ingress can lead electronics to malfunction.

- Hermetic packaging may be beneficial for applications with high performance, longevity or safety requirements.

- Truly hermetic seals can only be produced using inorganic, non-aging materials including metals, glasses, ceramics.

- Hermeticity may be more complex and costly to implement compared to technologies used to achieve IP68.

To learn more about hermetic packaging, please also refer to our article on when hermetic sealing is useful. You can also dive into a detailed definition of hermeticity, how is it tested, and what the difference between hermetic and quasi-hermetic packaging is.

You may also like

Want to know more? Let's talk

Whether you need more information or advice for a project, I would be delighted to talk to you.