Optical Metrology

Generally, optical metrology approaches follow these steps:

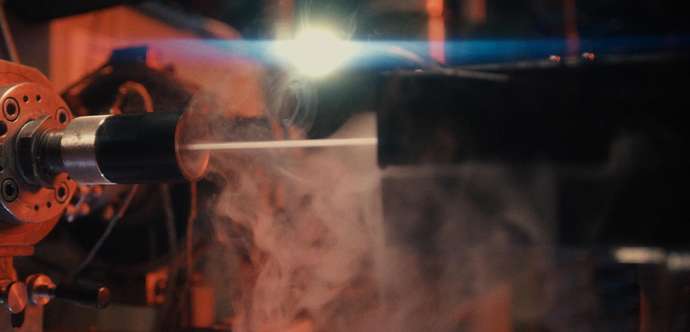

Illumination

A light source, often a laser or other coherent light emitter, is used to illuminate the object. Optical elements like fiber optic light guides, lenses, mirrors, or beam splitters can be used to control and direct the light path used for illumination.

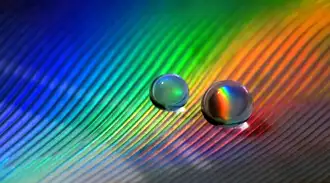

Interaction

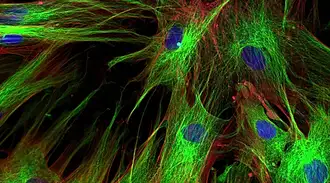

When light interacts with the object, the object’s characteristics cause it to change in various ways. This can modify the way the light is reflected, refracted, or absorbed, which creates changes in the intensity, wavelength, phase, or polarization of the light.

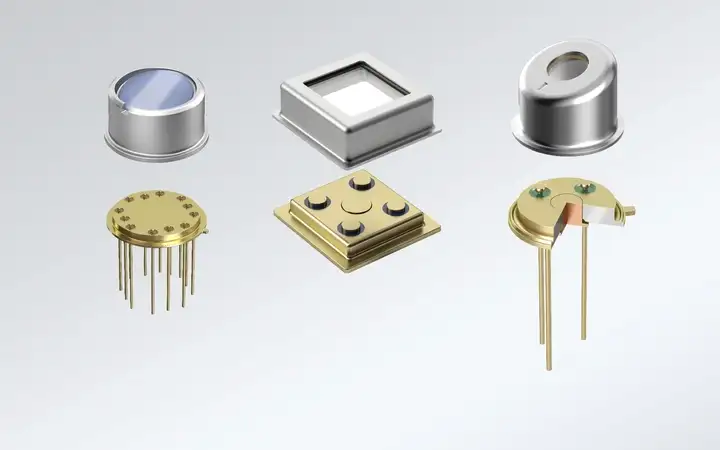

Detection

Detectors or sensors capture the modified light after it has interacted with the object. Measuring changes in the light’s properties provides important insights into the object's properties.

Optical metrology techniques

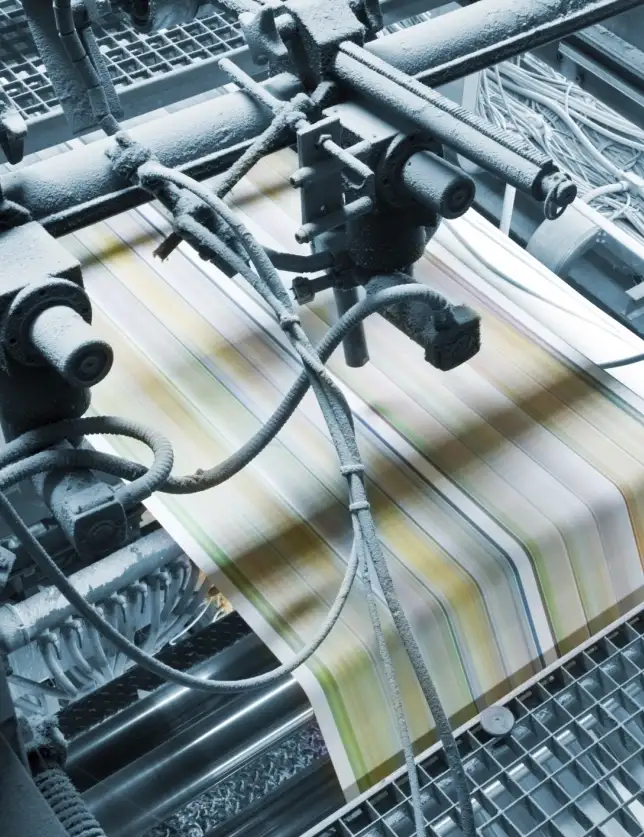

Typical applications for optical metrology

Thanks to its ability to provide precise and accurate measurements, a wide variety of industries and scientific fields rely on optical metrology. Some prominent application areas include:

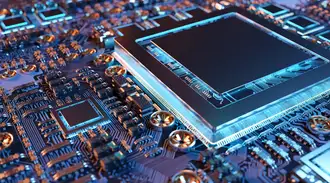

Specialty glass in optical metrology

SCHOTT’s specialty glass components and subassemblies — including fiber optic light guides, optical materials and components, and hermetic packaging — are essential in advancing optical sensing and metrology, where precision and accuracy are paramount. Our specialty glass materials are engineered to possess unique combinations of optical properties, such as low dispersion and high transmittance, which enable cutting-edge sensors and measurement instruments. By facilitating light manipulation, specialized glasses and components are empowering advanced signal detection and precise measurement.