Porous glass as a desiccant

Mitigating moisture where it matters most

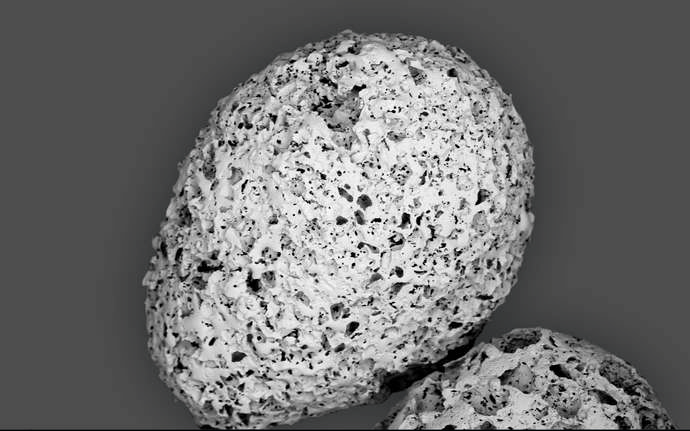

Moisture is a natural occurrence that is commonly encountered in everyday life. However, for sensitive high-performance electronics, the intrusion of moisture can have catastrophic consequences. Damage caused by moisture to electrical and optical components can lead to reduced functionality or even total failure.There are established methods for mitigating moisture presence in ordinary consumer products, but what about the circumstances in which even the slightest detectable presence of moisture can result in damaging effects? This is where porous glasses serve an important purpose: with substantial surface area and the appropriate surface chemistry, porous glasses can act as a high-performance desiccant to protect moisture-sensitive electronics in applications that include medical devices, precision optics, and CO2 lasers, among others.

The function and importance of desiccants

Desiccants are substances that act as drying or dehumidifying agents. The most well-known example of a desiccant comes in the form of a small silica-filled bag that is typically found in consumer products packaging. These packets keep things dry during shipping and storage. SCHOTT porous glasses perform an essentially identical function as silica packets. While silica packets keep a general environment of low moisture, SCHOTT porous glasses – with their rigidity and fully customizable shaping options – enable the desiccant to be tailored to the space and affixed securely. This is advantageous in uses where even minute moisture presence can be damaging.