Product Variants of FLEXINITY®

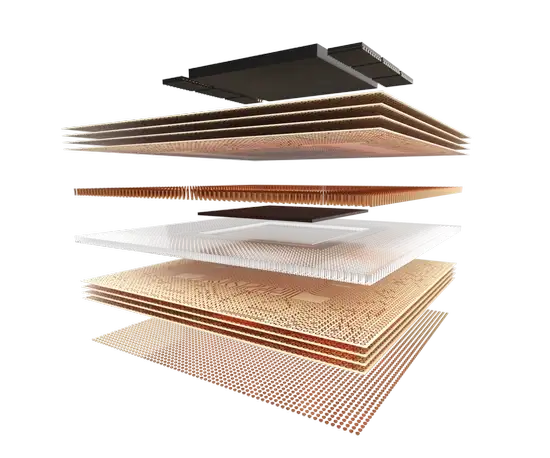

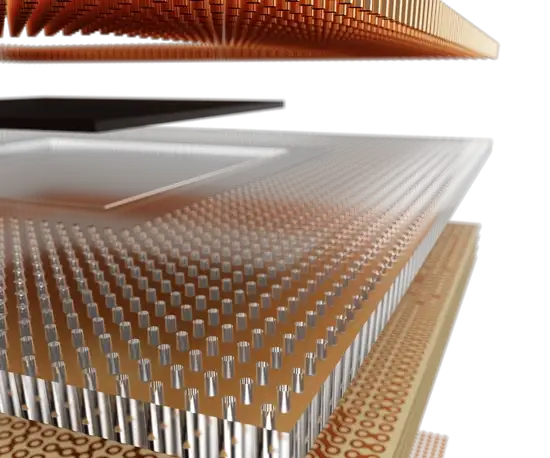

FLEXINITY® connect

CHARACTERISTICS

Tailored to handle the challenging demands of the advanced packaging industry, SCHOTT FLEXINITY® connect offers full design flexibility with the highest I/O counts and maximum end-product stability. FLEXINITY® connect combines the highest product performance with the lowest electrical loss and manufacturing costs.

YOUR ADVANTAGES

- Full design freedom thanks to the flexible positioning of Through Glass Vias.

- Straight hole shapes result in the lowest electrical resistance.

- Fast volume manufacturing process on large panels enables the highest I/O counts at the lowest costs.

- Adjusted thermal expansion for highest product yield and reliability.

- Large cavities with frames to embed your devices.

- Low dielectric constant to lower-end product power consumption.

FLEXINITY® mini

CHARACTERISTICS

Prompted by the opto-electronics and consumer industries, SCHOTT FLEXINITY® mini offers high strength, ultra-wide design flexibility, and superb quality in miniature form. As well as high geometrical accuracy and homogeneous edge cosmetics, FLEXINITY® mini can be provided with µ-scale through-structures. The convenience of in-frame delivery also gives customers the ability to clean and coat the glass quickly and cost-effectively.

YOUR ADVANTAGES

- Breathtakingly small detached glass parts between less than 10 mm and 1 mm.

- Near-unlimited geometrical variation combined with high precision.

- Dimensional and freeform tolerance of +/-10 µm in dimensions down to a few millimeters.

- Option for µ-scale through-holes.

- High homogeneity in edge quality with minimal chipping.

- Option for in-frame delivery for simple cleaning and coating.

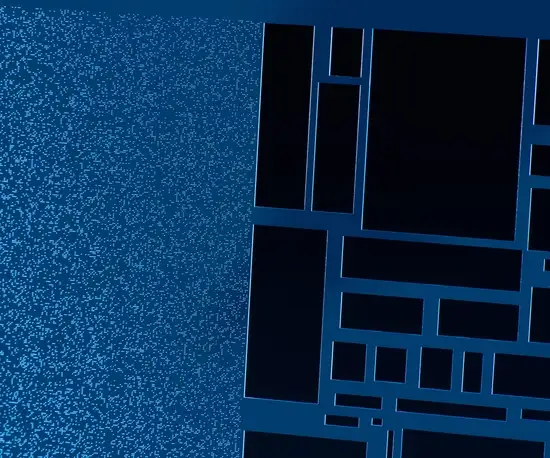

FLEXINITY® level

CHARACTERISTICS

FLEXINTIY® level is a material that is required by applications such as optical sensor housings or MEMS. Its main characteristics are 3D or 2.5D depth profiles. The base of blind holes or steps is matter, but it can be optimized to semi-transparence on request.

YOUR ADVANTAGES

- Supplementary features to FLEXINITY® or FLEXINITY® mini

- Limitless geometrical variation at high precision

- Dimensional and free form tolerance of +/-10 µm in dimension down to a few millimeters

- High homogeneity in edge quality with minimal chipping

- Straight walls both for blind holes and stepped bridges

- Increased design freedom for senors, MEMS and other miniaturized packaging modules