Media Kits

Everyone knows glass, but few know the possibilities of specialty glass. Every day, our 713 scientists and engineers work to make new technologies possible. Our founder laid the foundation for this 140 years ago with the invention of specialty glass. Today, our high-tech materials play a key role in the most important industries of today and tomorrow.

Here you can find Media Kits, focusing on our latest and most relevant topics – helping you to enhance your stories. In case you need further information, do not hesitate to contact us.

A press kit on SCHOTT Pharma can be found here.

Please use our press images in the following way

Our press images contain IPTC information. Our images can be used free of charge for editorial and scientific purposes. As an image source please use “Image: ©SCHOTT". Commercial use and transfer to third parties is prohibited. For any other use, you require the permission of SCHOTT AG.Annual results: SCHOTT remains stable despite uncertainties

SCHOTT closed fiscal year 2025 with stable revenue in a global environment shaped by uncertainty. The international technology group generated worldwide sales of EUR 2.83 billion. Earnings before interest and taxes (EBIT) amounted to EUR 230 million, reflecting the impact of rising costs, external factors, and an impairment.

Performance was supported by SCHOTT’s broadly diversified portfolio, particularly drug containment and delivery solutions from SCHOTT Pharma, as well as glass-to-metal seals and fiber-optic technologies. At the same time, SCHOTT made targeted investments and advanced key expansion projects to establish a strong foundation for future growth in markets such as augmented reality, semiconductors, and healthcare. Full financial details are available on the annual report page.

Images ©SCHOTT

News and Stories

Augmented Reality: New perspectives for everyday life

Augmented Reality (AR) seamlessly blends digital content with the real world, enabling new applications in both everyday life and professional environments. To move AR from a future promise to a technology ready for everyday use, high-performance, compact, and scalable optical solutions are essential. SCHOTT makes a key contribution to this.

By manufacturing reflective waveguides (SCHOTT® Geometric Reflective Waveguides) and high-refractive-index diffractive glass wafers (SCHOTT RealView®), the company supplies the core optical components for modern smart glasses. The successful transition of Geometric Reflective Waveguides into series production – including at the new manufacturing site in Malaysia – lays the foundation for producing smart glasses in large volumes at competitive costs. With this milestone, SCHOTT supports leading consumer electronics brands in bringing innovative AR products to the mass market.

Images ©SCHOTT

News and stories

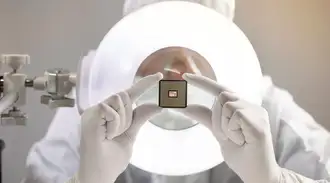

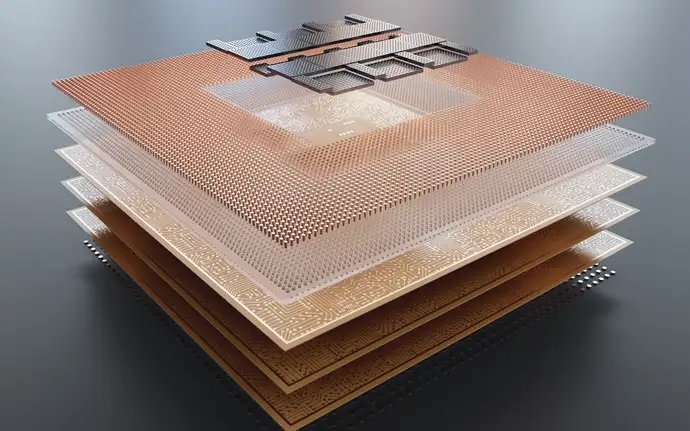

High-tech materials for next-generation chips

For over a decade, SCHOTT has been providing the semiconductor industry with specialty materials and components for high-precision lithography machines and measurement equipment, glass panels for next-generation packaging, and other high-end solutions.

Images ©SCHOTT

News and Stories

Materials for astronomy and space

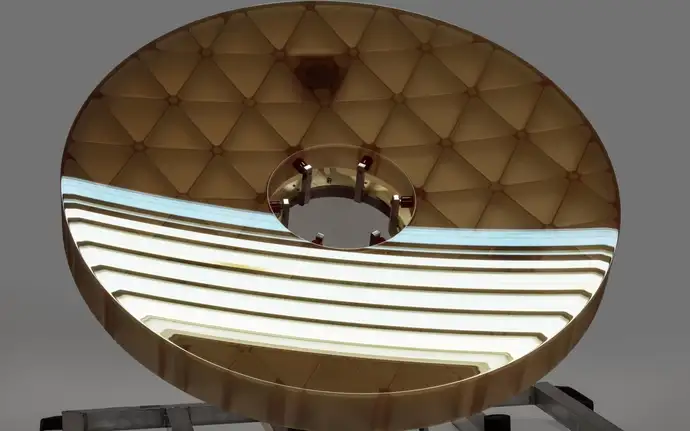

SCHOTT enables some of the world’s most ambitious astronomy and space missions with materials engineered for extreme precision and reliability. The company supplies high-performance glass-ceramics, specialty glass, and glass-to-metal sealings that withstand harsh space environments while delivering exceptional optical and mechanical stability.

SCHOTT materials are used in ground-breaking projects around the globe, including the European Southern Observatory’s Extremely Large Telescope (ELT), the world’s largest optical telescope, whose primary mirror substrates are made from SCHOTT’s ZERODUR® glass-ceramic. With its near-zero thermal expansion, ZERODUR® enables nanometer-level precision essential for exploring distant galaxies and advancing our understanding of the universe.

News and Stories

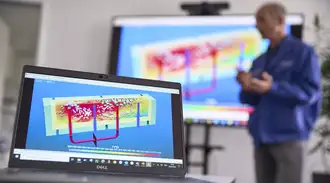

On the way to lower CO₂ emissions

Social responsibility has always been an integral part of our corporate strategy. The dividends we generate support a wide range of projects in scientific research and social programs. Today, taking responsibility has taken on new meanings. Progressive climate change is one of the greatest challenges of our time. We want to do our part to address climate change: By reducing CO₂ emissions through innovative melting technologies and energy efficiency, thereby gradually decarbonizing our energy-intensive production.

Images ©SCHOTT

News and Stories

Want to know more? Let's talk

If you need more information, please do not hesitate to get in touch.

Contact us