Product Variants of Eternaloc®

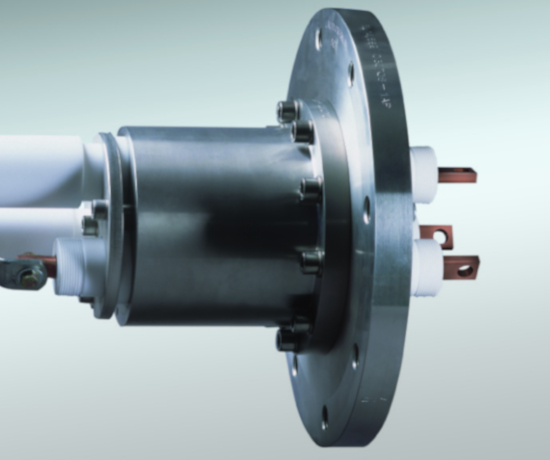

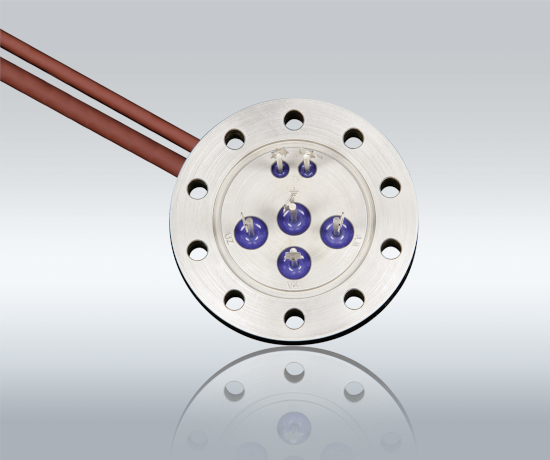

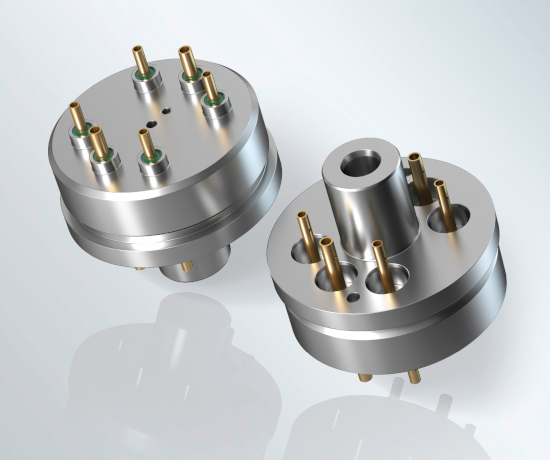

Eternaloc® Liquefied Gas Terminal Headers

SCHOTT Eternaloc® terminal headers are the safest, most proven components available in the market.

SAFE

- Resistant to extreme pressure and thermal shock.

- Compliant with ATEX and IECEx, as well as local regulations.

- 100% final inspection quality assurance process.

PROVEN AND MAINTENANCE-FREE

- Proven reliability in thousands of liquefied gas applications worldwide since 1985.

- Maintenance-free reliability reduces total cost of ownership.

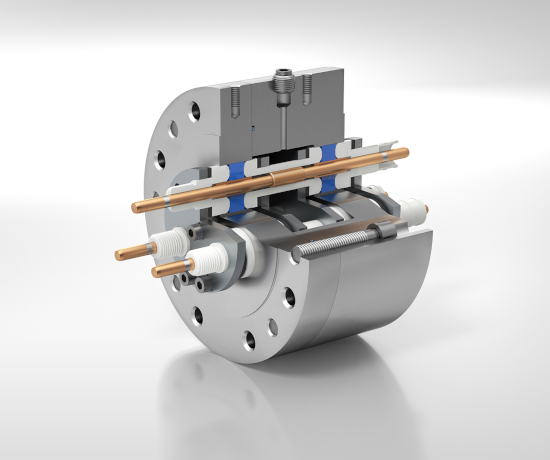

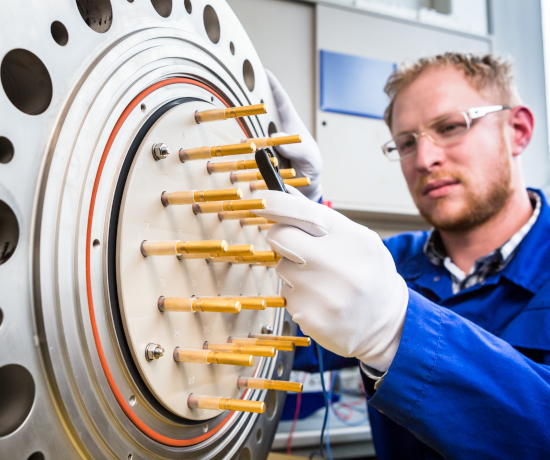

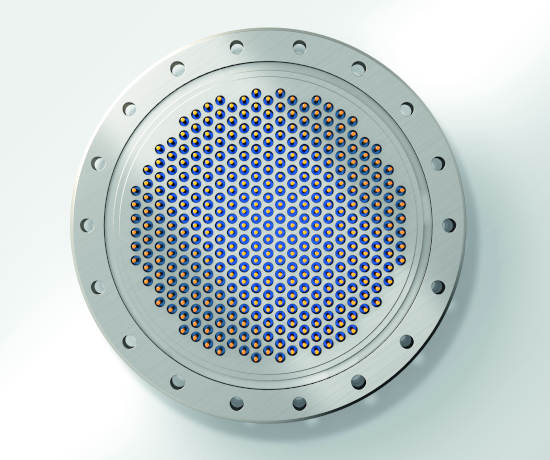

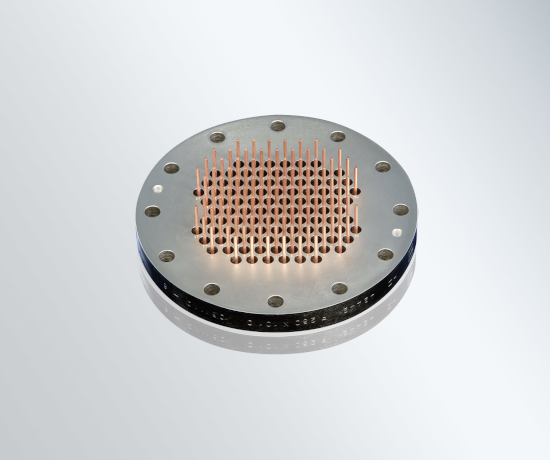

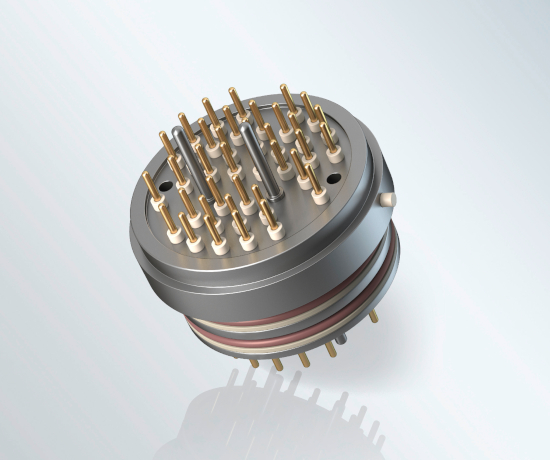

Eternaloc® Nuclear Penetration Assemblies

SAVE AND BE SAFE

- Manufactured using only inorganic, non-aging glass-to-metal sealing with unique compression technology.

- Proven to withstand extreme pressure and thermal shock.

MAINTENANCE-FREE

- Performing maintenance-free in more than 100 nuclear power plants worldwide since 1962.

- Maintenance-free reliability reduces the total cost of ownership.

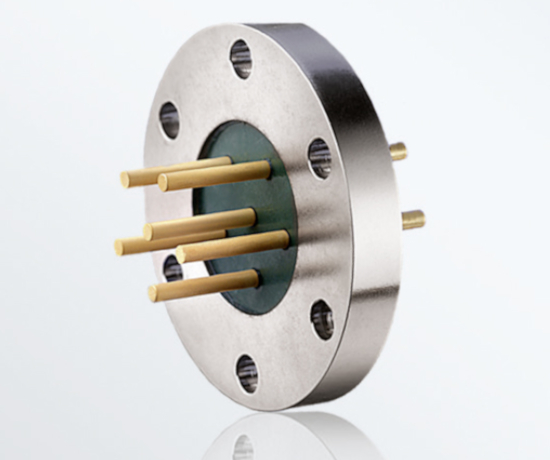

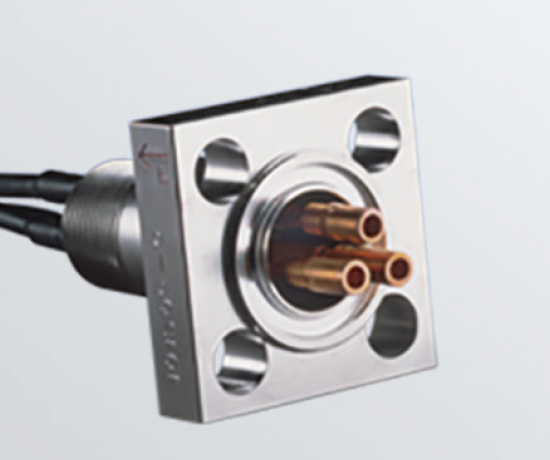

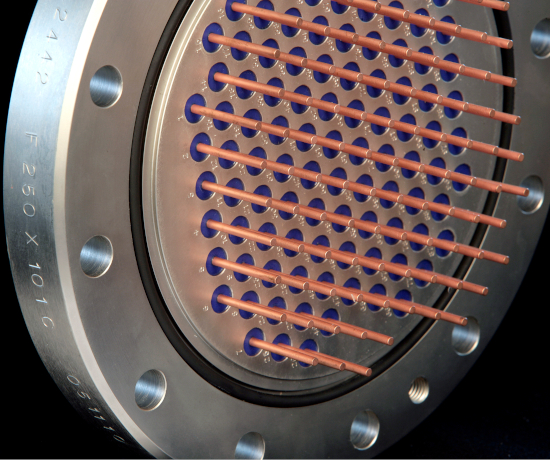

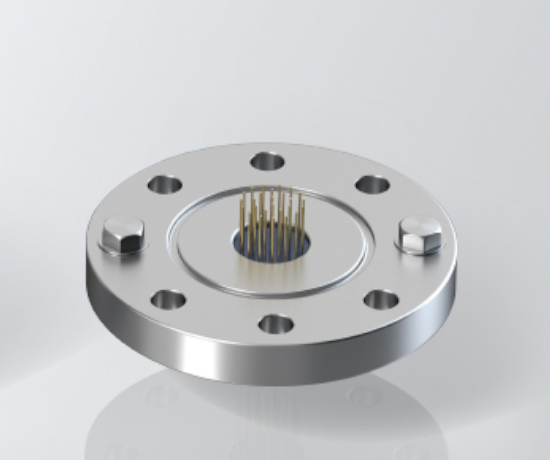

Eternaloc® Compressed Gas Lead-Through Plates

SCHOTT Eternaloc® lead-through plates are:

- Extremely robust, reliably gas-tight, proven and tested.

- Customizable according to your requirements.

- Available with explosion-proof certification.

- Maintenance-free, reducing total cost of ownership.

- Available with complete electrical assembly.

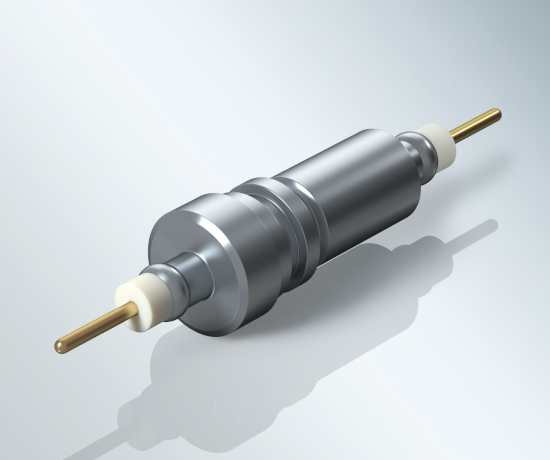

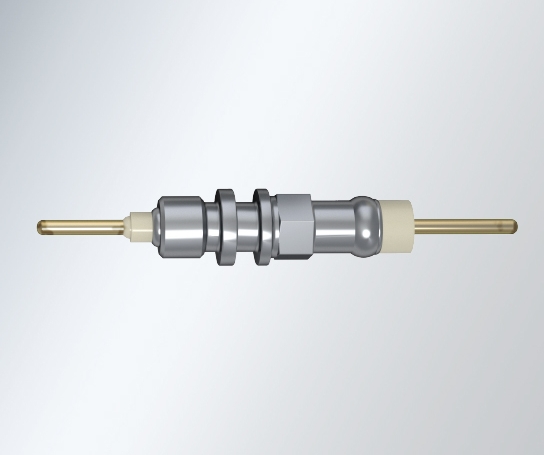

Eternaloc® Oil and Gas Connectors, Feedthroughs and Penetrators

The specific advantages of Eternaloc® connectors vary depending on the application:

- In subsea Christmas tree electronics, such as wellhead pressure sensors, it's the long-term maintenance-free reliability over many years that counts.

- In exploration equipment in downhole drilling applications, including wireline, MWD and LWD, SCHOTT’s components provide superior HPHT robustness above 35,000 PSI with outstanding pressure and insulation resistance under extreme conditions.

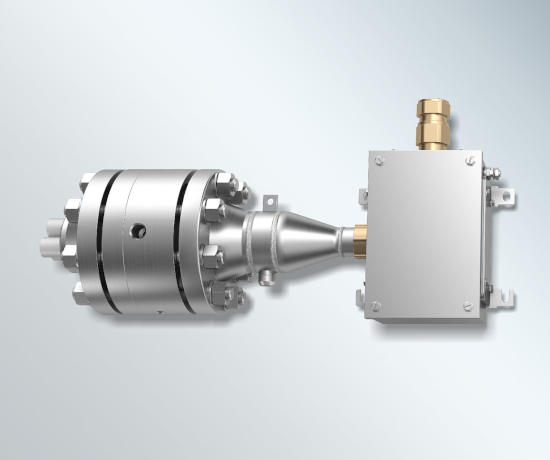

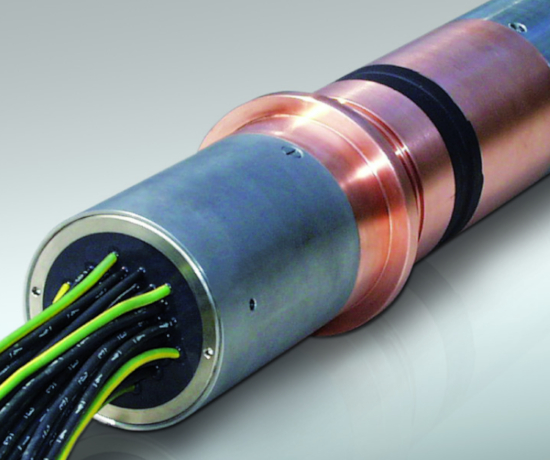

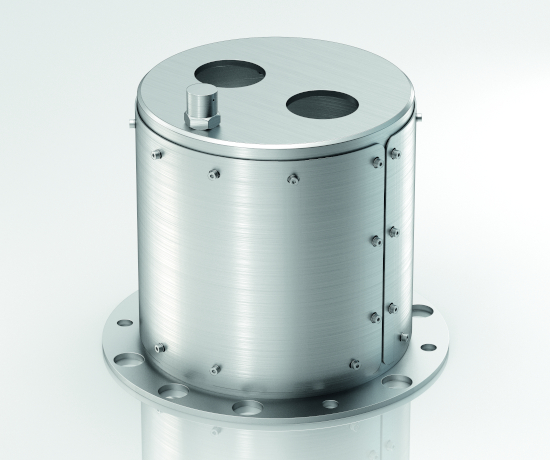

Eternaloc® Submarine Penetration Assemblies

Thanks to the use of superior materials and technology, SCHOTT’s Eternaloc® bulkhead penetrators offer:

- 40-year lifetime, making them a 'fit and forget' component capable of lasting for the average service lifetime of most nuclear submarines.

- Provide increased safety.

- Reduced total cost of ownership.

- Trusted by the world’s most renowned naval forces, including supplier awards from BAE Systems.