Product Variants of CoralPor® Porous Glasses

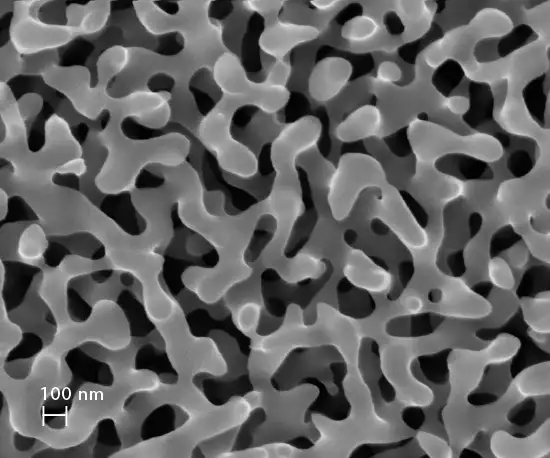

CoralPor® Nano-Porous

YOUR ADVANTAGES

- Excellent absorption and separation capabilities due to very large internal surface area and narrow pore size distribution

- Enabling stable results and efficiency due to ultra-robust, long-lasting material. Properties include:

- Low coefficient of thermal expansion

- High thermal stability

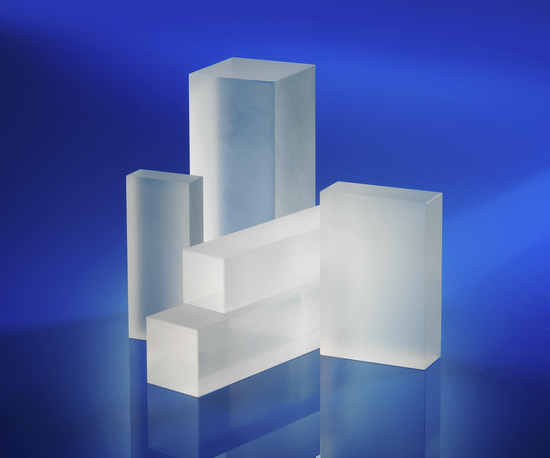

- High chemical resistance against a large variety of different media - Available as a powder or monoliths in various shapes and sizes

APPLICATIONS

Examples include:

- As a substrate in synthesis processes e.g. for enzymes

- Thin layer chromatography

- Ultra- and microfiltration

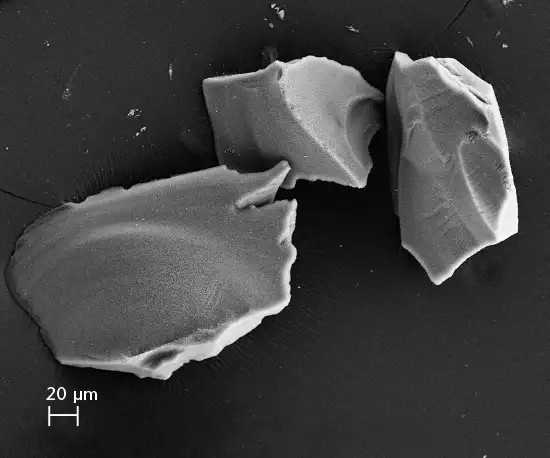

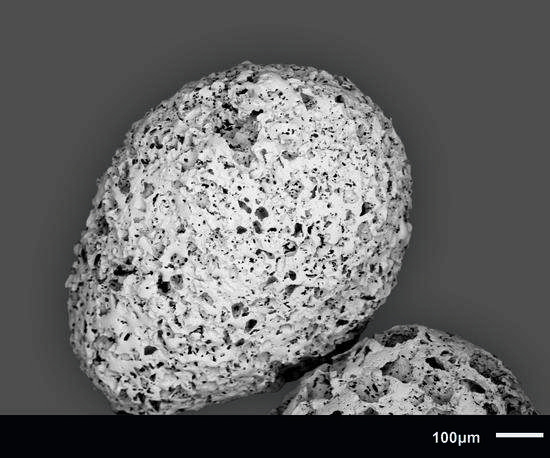

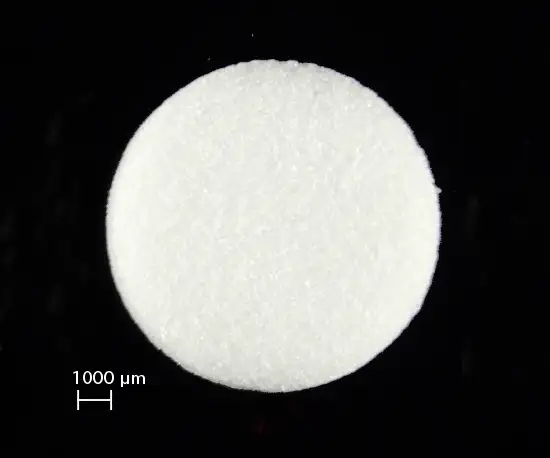

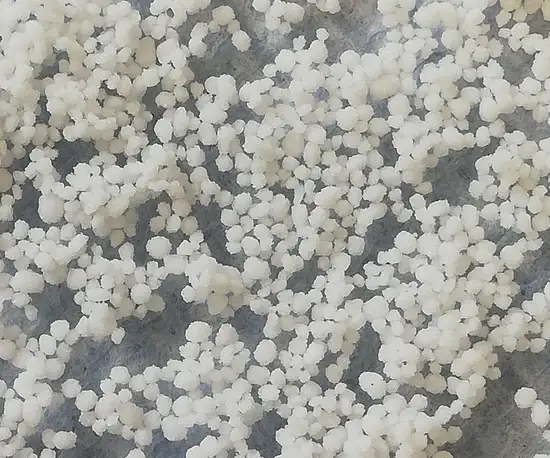

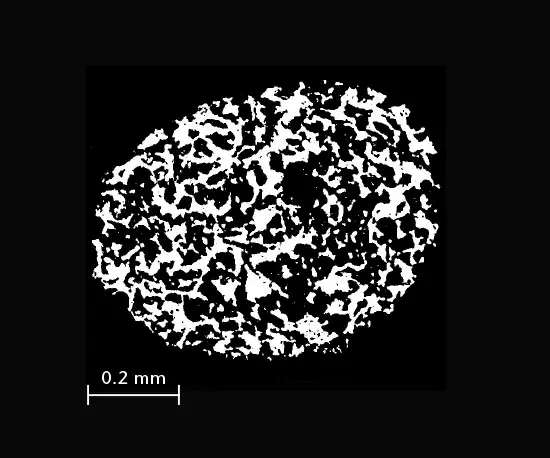

CoralPor® Macro-Porous

YOUR ADVANTAGES

- Excellent thermal stability depending on base glass

- Completely inorganic

- Customized surface treatment upon request

- CoralPor® Macro-Porous Glasses can be produced:

-With an average pore size between 1–500 μm

-A pore volume of up to 80%

-As sintered monoliths in various shapes and sizes

-As porous microspheres / powders

APPLICATIONS

Examples include:

- As a substrate in synthesis prcesses e.g. for bioreactors

- Microfiltration

- Carrier for liquids or active substances, such as evaporation units in e-cigarettes or vaporizers

David Bühlmeyer

Sales Manager Europe