Technical Details of Hermetic Packages for LiDAR Sensors

LiDAR sensors must deliver continuous high performance in challenging automotive environments. Sensitive optical LiDAR components need reliable packages for long-term protection against harmful elements. These packages must simultaneously offer precise optical interfaces and exceptional thermal dissipation properties to achieve stable laser wavelengths.

Advanced designs and processes for exceptional performance

Vacuum Tightness

- Our hermetic packaging technology allows the implementation of tailored and controlled internal pressure environments (typically < 1x10-8 mBar*l/s).

- Hermeticity enables the required internal pressure to be maintained over an extremely long time period.

Reliability

Corrosion resistance

- Humidity test: 85⁰C, 85% RH, 1000 hours.

- Salt spray test: 35⁰C, 0.5 - 3% salt concentration, 24 hours.

Thermal stability

- Thermal shock: -65 to 150⁰C, 15 cycles.

- Soldering compatibility: 260⁰C for 5 minutes.

Plating stability

- Bake test: 425⁰C for 15 minutes (no plating discoloration or blistering).

- Solderability of leads: wet homogenously with stains / bare spots <5%.

- Mandrel test: leads to be coiled at 1mm diameter, 2-6 coils with no plating blistering or peeling.

Mechanical stability

- Leads twisting and bending with load: 56g for pin diameter Ø0.25 ~ 0.29mm, 85g for pin diameter Ø0.3 ~ 0.5mm.

- Tensile test: 10N for pin diameter 0.20-0.29mm, 23N for pin diameter 0.30-0.50mm.

Thermal Conductivity

- Optimized thermal material (CuW, OFHC) choices available: copper thermal conductivity = 385 W/m-k.

- TEC (thermoelectric cooler) designs and ceramic multilayer substrates are also available.

Optical

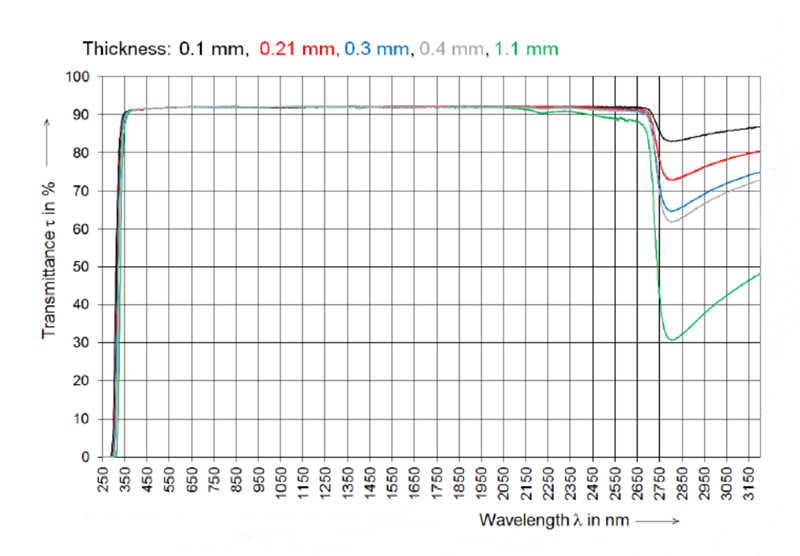

- Windows, lenses and coatings available for improved optical transmission and reduced reflection.

- High transmission glass in 905 - 1550nm range.

- Glass filters / coatings.

- Angled window caps also available.

Optical Emission Direction

- Vertical emission for VCSEL, as with TO packages.

- Horizontal emission for edge-emitting laser diodes.

Mechanical

Through Hole and SMD Technology

- THT: Through Hole Technology – particularly reliable for environments with mechanical vibration / shock.

- SMD: Surface Mount Technology – particularly reliable for packages with lower mass.

Sealing methods

- Projection welding – fast, economical, low heat dissipation to the chip.

- Seam sealing – rectangular package, seal in array form.

- Eutectic soldering such as AuSn – <350⁰C.

- Laser welding – high precision.

Electrical

Insulation Resistance

- Feedthrough insulation > 1x10^10 ohm at 50% RH, 100V.

Mei Shan Lua

Product Manager