When is hermetic sealing useful?

The challenge

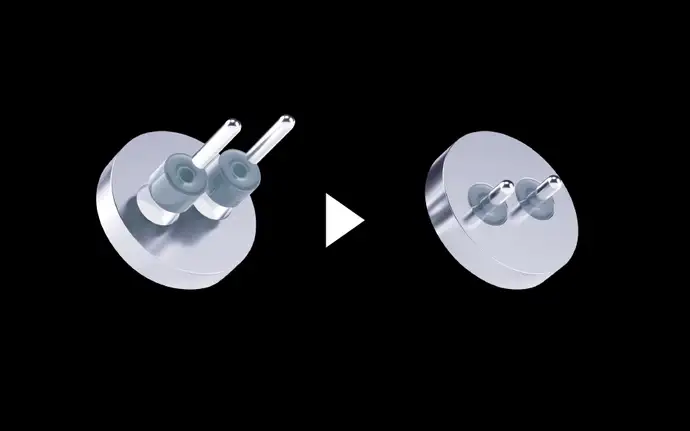

A challenge many engineers face every day is how to prevent the intrusion or leakage of moisture or gases while simultaneously enabling electrical or optical signal transmission. Extremely sensitive electronics and electrical systems, opto-electronic components, and electro-chemical substances need to be protected against environmental influences especially harmful moisture and gases.The best protection – a closed metal housing – is usually not a viable solution because electrical power and signals must be able to pass through (into and out of) the sealed enclosure. Technology known as hermetic sealing and packaging has been used for decades to enable signal transmission while remaining water- and air-/gas-tight. Hermetic seals can come in the form of electrical housings, (cable) feedthroughs, connectors or penetrators, headers, or conductor terminals. Hermetic sealing is also used for optical signal transmission, for example by encapsulating a sensor and capping it with a reliably vacuum-tight optical lens or window cap.

The only option in harsh operating conditions

Hermetic packaging of electronic components or systems is often a requirement when harsh or advanced operating conditions apply. Examples include automotive electronics, safety-relevant nuclear power, medical device electronics and more.Typical use case - extreme conditions

Hermetic seals are often used in applications where electronics need to reliably function despite high/low temperatures, high moisture levels, high pressure, or aggressive chemicals.

Increasing system reliability and safety

Beyond challenging operating conditions, hermeticity can be beneficial in case of special longevity or efficiency requirements. This includes applications that cannot compromise on safety or reliablity (such as automotive airbags or defense electronics) or where maintenance, repairs, or exchange of an electrical system is impossible or would result in prohibitive costs – as is the case in many avionics, aerospace, and maritime applications.

Performance, efficiency, and design innovation

Airtight hermetic seals can also enable significant performance and efficiency improvements, as well as innovative designs. A truly air-, or water-tight housing is needed to enable long-term and consistently high-performance data transmission in opto-electronic data- and telecom applications.

Hermetic packaging may also be a cost-efficient alternative to non- or quasi-hermetic seals, as it can allow smaller, miniaturized, and simplified single-component designs, instead of larger, more complex multi-components systems. Hermetic seals can also be designed to cater to increased heat dissipation, high power/ voltage/ insulation, or high frequency / RF optical data transmission requirements.

Hermetic packaging: connected & protected

Vacuum-tight hermetic packaging and sealing serves an essential purpose of enabling reliable functionality of electronic devices and systems – especially in harsh and / or inaccessible environments. It is established and trusted in prominent industries worldwide, including automotive electronics, nuclear safety, medical devices, and many more. Hermetic sealing adds value and even fulfills requirements as the only viable electronics protection solution in applications that help keep everyday life moving worldwide.

You might also like

Want to talk directly to an expert?

Let’s discuss how glass-to-metal sealing can be a fit for your application.