Titanium hermetic packaging

What is glass-to-titanium sealing?

Glass-to-titanium sealed hermetic components are created using a specialized glass-to-metal sealing technique. In this process, titanium functions as the housing material while specialty glass provides electrical insulation and enhances RF functionality. This produces durable, hermetically glass-sealed titanium packages, headers, and feedthroughs that reliably protect electronics while delivering all the advantages of titanium.

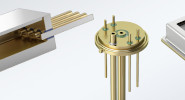

Titanium packages

Titanium connectors

Titanium-framed windows

Titanium battery seals

Titanium weld inserts

Benefits: Why hermetic titanium packages are unique

Titanium is a versatile and reliable material, ideal for demanding applications that require high performance, durability, and customization to specific requirements. Discover its unique benefits for packages:

Applications

Titanium’s unique combination of properties makes it an ideal material for packaging, encapsulating, and connecting electronic components, especially in challenging environments.

Technical details

SCHOTT leverages decades of experience in glass development, laser welding, active brazing, and material bonding to deliver tailored solutions. From mastering the fundamentals of glass-to-titanium sealing to supporting new processing techniques, SCHOTT combines precision engineering and in-house capabilities to enable robust, high-performance hermetic components.

The following Q&A explores key technologies and processes that enable SCHOTT to meet titanium hermetic packaging requirements.

Glass-to-titanium sealing is a highly specialized technology that draws on advanced specialty glass know-how and glass-to-metal sealing expertise. Specially formulated glass enables the reliable joining of titanium and glass, materials that are typically difficult to combine. Careful surface preparation is required for reliable adhesion, despite titanium's natural tendency to form surface oxide layers.

With precise heat management, controlled assembly processes, and thorough post-sealing control, we can manufacture robust, hermetic seals that meet the highest standards of reliability and durability. SCHOTT’s advanced expertise allows us to deliver these complex components for demanding applications.

SCHOTT’s modular approach and in-house capabilities provide customers with tailored solutions for even the most complex titanium hermetic packaging requirements. From active brazing, laser welding, and titanium-nickel bonding to using MIM parts for cost-efficient manufacturing, we combine materials knowledge and precision engineering to deliver reliable, high-performance products for demanding industries.

Comprehensive solutions for titanium hermetic packaging

Beyond our extensive glass expertise, SCHOTT offers a wide range of modular solutions to address the challenges of titanium hermetic packaging and create additional value for our customers. These solutions enable us to handle complex designs, integrate multiple functionalities, and offer long-term reliability in demanding applications.

Titanium hermetic packages often require intricate designs to meet specific application needs. Our experience in combining materials and advanced manufacturing techniques allows us to handle even the most complex requirements:

- Electrical feedthroughs: Our glass-to-titanium sealing technology provides reliable hermeticity and electrical insulation for feedthroughs.

- Optical windows: Integrating optical windows into titanium housings requires advanced processes such as active brazing and laser welding.

- Thermal management: Materials used in hermetic housings often exhibit vastly different thermal expansion coefficients. SCHOTT has developed reliable processes for integrating common heat sink materials such as molybdenum into titanium housings for optimized heat management.

- Surface modification: Surfaces can be post-treated to generate solderable or wire-bondable conditions. Also, selective process options are available.

As a glass inventor, SCHOTT’s ongoing in-house glass development is the “secret sauce” for advancing titanium hermetic packaging. We create and refine glasses that are specifically designed to bond directly with titanium. Our ability to control the entire development process—from material innovation to final production—offers superior quality and performance and allows us to develop entirely new glass formulations tailored to meet unique customer or application-specific requirements. This gives SCHOTT a distinct advantage in delivering cutting-edge solutions for demanding applications.

- Advanced autoclavable glass for titanium packages in medical applications

Traditionally, CaBaL12 glass was used with titanium medical devices due to its established compatibility. However, this glass has limited hydrolytic resistance after extended use, particularly under repeated autoclave cycles. To address this challenge, SCHOTT developed advanced autoclavable glasses that bond directly with titanium, providing durability, enhanced hydrolytic resistance, and reliable long-term performance.

- Implantable glass for titanium packaging with proven biocompatibility

With titanium-sealing glasses for implantable devices, the number of components for hermetic seals can be reduced, allowing smaller footprints and highly customized designs.

- High-performance sealing glass for hermetic titanium components in high-pressure, high-temperature (HPHT) applications

SCHOTT sealing glasses, designed for extreme (HPHT) environments, directly bond with titanium to create robust hermetic seals. These glasses are engineered to withstand high temperatures and intense vibrations, meeting the stringent demands of oil and gas applications, for example. The combination of titanium packaging and SCHOTT’s specialized glass know-how offer exceptional and consistent component quality.

SCHOTT’s in-house laser welding expertise enables the design and manufacture of precise hermetic seals with minimal heat-affected zones, preserving material properties and meeting tight tolerances. For titanium packages, we can process small components and integrate them into larger titanium housings. Examples include:

- Connectors and ports: These components can be individually processed, plated, and hermetically welded into the housing to create complex, multi-functional packages.

- Solderable coatings: Solderable surfaces can be integrated where needed, enabling easy assembly of other components in customer systems.

- Corrosion-resistant weld seams: Welded areas regain a passive surface after welding, providing long-term corrosion protection.

Active brazing is a core capability at SCHOTT, enabling us to deliver high-performance, hermetic solutions for demanding applications in industries such as medical, aerospace, and energy. Here are two examples:

- Sapphire-to-titanium bonding: Sapphire, a preferred material for optical windows, cannot be bonded using standard solders without proper metallization. SCHOTT uses a specialized active brazing process with a titanium-containing braze to directly bond sapphire discs to titanium frames without the need for additional metallization.

- Molybdenum and titanium integration: Active brazing enables robust connections for molybdenum and titanium, supporting complex thermal management solutions and high mechanical stability.

Many customers don’t realize that metal injection molded components can be hermetic, assuming some porosity is always present. SCHOTT has demonstrated that MIM can deliver both hermeticity and cost efficiency:

- Hermeticity: MIM components can be designed and manufactured to meet strict hermeticity standards, making them suitable for critical applications.

- Cost efficiency: Especially for higher production volumes, MIM parts are significantly more cost-effective than traditionally milled titanium housings, making them ideal for large-scale applications.

Products

Explore SCHOTT’s custom-designed products featuring glass-to-titanium sealing technology. The image gallery showcases examples designed for demanding applications across industries. To dive deeper, visit the links to related product pages where this innovative technology can be applied.

Want to know more? Let’s talk.

Whether you need more information or advice for a project, I would be delighted to talk to you.