Converting and reshaping

SCHOTT applies more than 140 years of experience and expertise to the techniques of converting and reshaping, which has led to a vast array of industry-leading products with outstanding technical properties that meet the most demanding requirements.

What is converting and reshaping?

Glass and glass-ceramic products such as sheets, tubes and rods are made by direct molding from hot molten glass. When a customer has special requirements, glass can be reheated and fed to a downstream forming process. This is called converting or further processing.

SCHOTT has been developing this expertise over many decades to serve a single purpose: to produce glass products with the exact properties and dimensions for our customers’ needs. Whether it is a simple 90-degree bend in a glass-ceramic fire viewing panel or millions of pharmaceutical vials for a global vaccination project, we offer a combination of the highest quality materials, the latest processing equipment, and in-depth knowledge of the glass material.

Advantages of our converting and reshaping expertise

The benefits of SCHOTT’s expertise in converting and reshaping are seen in our high precision, market-leading products. For example, with our curved shapes or angular bent ROBAX® glass-ceramic panels, we enable fireplace manufacturers to design innovative and stylish fireplaces with an enhanced view of the fire. In addition, our hot forming technology leads to unique shapes and dimensions, more homogenous inner surfaces, and excellent E&L profiles in pharmaceutical packaging products.

Types of converting and reshaping

1. Converting for pharmaceutical packaging

Glass tubing is processed into a variety of pharmaceutical containers with a range of key properties, such as high strength and chemical resistance, as well as tight tolerances.

2. Further processing of glass tubes and rods

Creating a variety of uniform shapes with strong mechanical and chemical properties, glass tubing is evenly heated for further processing.

3. Bending of glass and glass-ceramic sheets

Flat sheets can be formed in different ways – for example, curved or angular bent forms with different radii.

4. Bending of glass tubes

Glass tubes and rods can be bent by heating them evenly before shaping, creating products with a wide range of specifications and attributes.

5. Glass pressing

Pressed blanks are shaped into high quality optical glasses like lenses or prisms using hot processing under pressure.

Converting and reshaping methods

The incredible versatility of glass and glass-ceramics, and their ability to be bent, shaped, and converted, not only provides our customers with products of the exact dimensions and shapes for their application, but delivers long-lasting high performance in a number of ways.

Converting for pharmaceutical packaging

SCHOTT’s high-quality glass tubing can be converted into a range of unique pharmaceutical containers. The containers not only feature high strength and chemical resistance but also offer exceptionally tight tolerances and consistent performance.

Our pharmaceutical packaging portfolio has a global reputation for the secure storage of sensitive drugs, as well as exceptional strength and a wide range of products. Our in-depth knowledge of converting processes has resulted in several key industry innovations.

For example, EVERIC™ strong vials offer increased strength in side compression and axial load, while EVERIC™ pure vials feature improved bottom forming that results in a reduced risk of delamination. Our converting expertise is also applied to prefilled syringes, which exhibit an excellent E&L profile for the protection of highly sensitive drugs.

YOUR ADVANTAGES

- Improved container (vial) strength.

- Ideal for low-fill, highly sensitive drugs.

- Conform to all major international standards for pharmaceutical packaging.

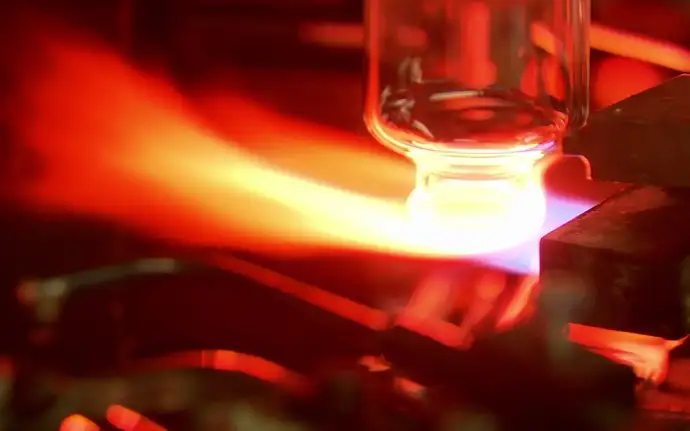

Further processing of glass tubes and rods

SCHOTT products created by the further processing of glass tubes or rods achieve highly impressive technical properties across a wide variety of shapes, sizes, and forms. This makes them suitable for many demanding and specialist applications.

DURAN® glass tubes and rods are formed into the desired shape by lathe processing at very high temperatures. The glass tube is held and evenly heated from all sides while rotating. Once the desired temperature range is achieved the glass tube can be reshaped or joined with other pieces. Products created by this process include Y-pieces, T-pieces, spirals, and complex manifolds, to name a few.

Beyond that, additional processing steps like drilling, cutting, grinding, flange forming, etc. are also possible – all made directly by SCHOTT.

YOUR ADVANTAGES

- Facilitates highly versatile shaping and customization.

- Wide range of geometries possible.

- One-stop-shop for further processed tubing.

DURAN® is a registered trademark of DWK Life Sciences GmbH.

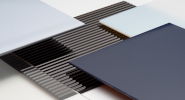

Bending of flat glass and glass-ceramic sheets

SCHOTT utilizes a number of glass bending processes to carefully shape glass and glass-ceramic plates to create innovative, attractive, and robust products for demanding applications and environments.

The bending processes require high and specifically adjusted temperatures. Once a glass plate has been heated to the required level, it is shaped using a press/bending procedure or sagging process to achieve the requested form. A range of different techniques can be applied to tailor this process to the required application.

YOUR ADVANTAGES

- Suitable for a wide range of sheet or panel sizes.

- Variation of multiple bending radii possible.

- Competitive advantages though highly customized products.

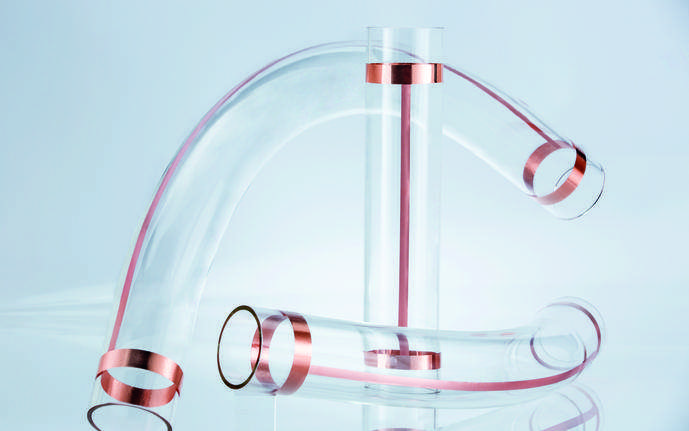

Bending of glass tubes

As the world’s leading manufacturer of glass tubing, SCHOTT offers a wide range of high-end products created using bending technology.

One example is DURAN® borosilicate glass tubing with high-precision bends for pneumatic conveying systems. This offers an effective solution for the transportation of abrasive and corrosive materials, which deteriorates much less rapidly than its stainless steel alternatives. In the automated bending process, heat is applied to a defined area to curve the glass tubing to a pre-determined radius. After the forming process, copper conductive tape is applied.

For bending glass tubes, a manual forming process is also possible. As DURAN® enables optimum light input for bio-secure algae cultivation, the same glass tubing is ideal for the U-bends and J-bends used in photobioreactor systems.

YOUR ADVANTAGES

- Precise tolerances for easy installation.

- Wide range of possible geometries.

- Mechanically durable and long-lasting performance.

- CTE remains after converting process.

DURAN® is a registered trademark of DWK Life Sciences GmbH.

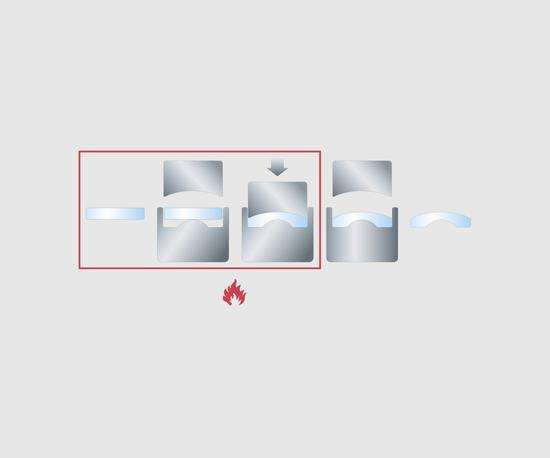

Glass pressing

Along with the more common hot processing methods, SCHOTT manufactures a range of customized glass products using carefully modified techniques. One of these techniques is pressing, which is suitable for high volume production of precise optics.

Pressing begins with the production of a two-part mold, which meets high standards for precision, surface quality and wear resistance. The cavity of this mold is then filled with a round or square glass disc, before being heated. After heating, the glass can be pressed by the mold to the required shape, then cooled to create the final product.

YOUR ADVANTAGES

- Pressing allows for customization while optical properties are maintained.

- Offers less processing time and more cost savings for the customer.

- Glass can be taken directly from the melt (primary forming) or be present in a solid state and reheated (forming).

- Offers a wide range of unconventional geometries.

Why SCHOTT?

SCHOTT has consistently maintained its reputation as a world leader in specialty glass and glass-ceramic products over many decades. That status is reinforced by a commitment to market-relevant innovations, driven by an ongoing passion for expanding the limits of glass.