From light to laser

Based out of Duryea, Pennsylvania, SCHOTT’s Vice President of Research and Development for North America, Bill James, tells us all about his favorite material: laser glass. We wanted to find out why this material is so special to him.

What is laser glass and how does it work?

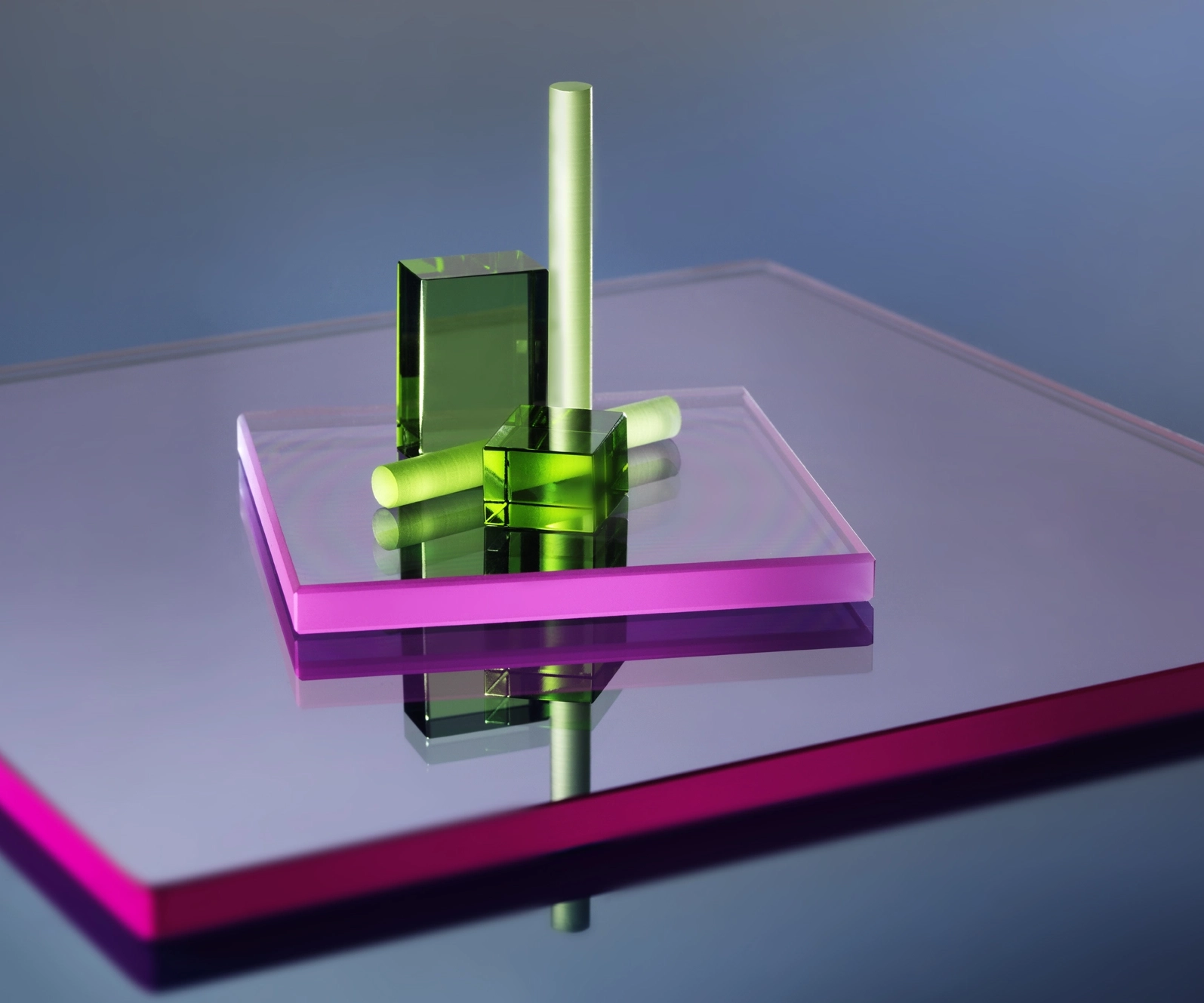

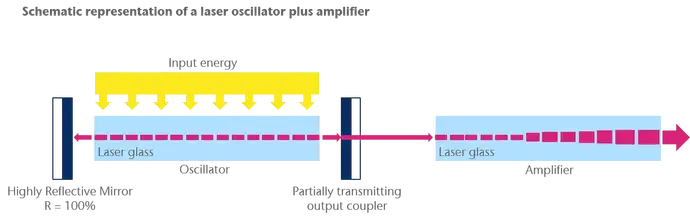

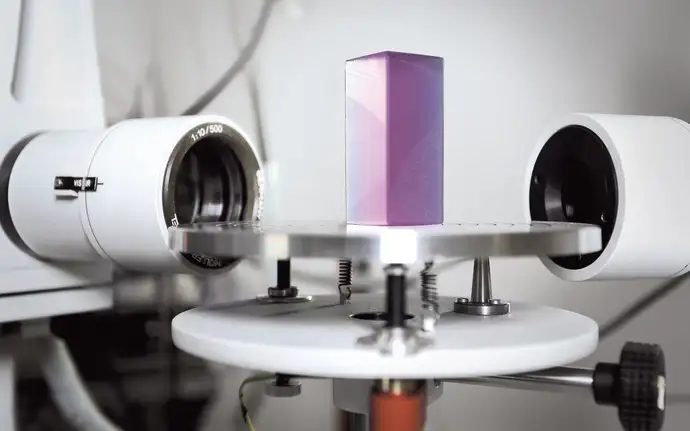

Laser glass is an active solid-state material with the ability to amplify light by stimulating radiation emissions. The glass is first pumped with a source of energy, for example, light from a flashlamp or diode, and that energy is absorbed and stored in the glass. Once the laser pulse passes through the glass, the stimulated emission process extracts the stored energy, resulting in a more intense laser beam.

That sounds complex. What excites you about laser glass?

Throughout my studies at the University of Scranton, Purdue University, and now during my professional career, lasers remain one of my favorite tools to interrogate the world around me. They are essential in gaining an understanding of how light interacts with molecules and materials. For example, at the right wavelength and under the right conditions, a laser interacting with a protein or peptide can change shape to mimic protein folding or unfolding in the human body. Here in Duryea, together with our colleagues in Germany, we are developing laser glasses that are being used in some of the most exciting applications. Right now, we are working on laser glasses that are expected to have a significant impact on understanding fusion reactions, which may lead to the power plants of the future.

What are today’s applications of laser glass?

Laser glass is used in a number of industries today, for example, to perform medical treatments. In dermatology, medical devices use laser glass to remove scar tissue, hair, or tattoos. When it comes to mobility, laser glass enables autonomous driving by providing the light pulse for the range measurement. Laser glass is also used in advanced measurement systems to push science beyond the cutting edge. And, I would be remiss if I didn’t mention the role SCHOTT laser glass plays in today’s fusion energy research, where some of the most promising results from large fusion research facilities, such as the National Ignition Facility at Lawrence Livermore National Lab, were achieved using our laser glass!

Are there different types of laser glass?

Yes, indeed. Owing to the fact that there are a variety of host matrices, lasing ions, and lasing ion concentrations – or doping levels to use field-relevant lingo – available to material developers, there are quite a few different types of laser glass. Based on decades of development and understanding, developers at SCHOTT we utilize specific combinations of host matrix, lasing ions, and doping levels to create unique materials that generate laser light at different discrete wavelengths and exhibit specific properties. For example, one development program resulted in a product line of ‘eye-safe’ laser glass for laser range finders, while another led to a deep understanding of the thermomechanical properties of a different host matrix, lasing ion, and doping level combinations for high repetition rate laser systems.

How does laser glass push physical limits?

As an example, the interaction of high-intensity laser radiation from glass-based systems with matter can create extreme energy on Earth in a controlled laboratory environment. This interaction of laser light and matter can even mimic temperatures and pressures similar to those inside the sun, resulting in the release of significant amounts of energy. The harnessing of this energy, of course, has enormous potential as a green energy alternative to fossil fuels. In addition, the by-products of this interaction, such as X-rays, charged particles under near-relativistic conditions, and high neutron counts, are all sparking interest in new applications. One example is the direct imaging of biomolecules by neutron radiography. Another example is the potential for compact generators for radioactive isotopes located within individual medical facilities. In any case, I am sure that laser glass will continue to be a pioneering technology enabling research and many industrial applications for a long time to come.