Solving the e-mobility puzzle

Higher driving range, lower prices, improved safety, and ever-growing charging speeds: Solid-state batteries could provide the lift electric cars need to increase mass-market adoption. Go inside a vacuum-sealed lab for a look at groundbreaking material research for next-gen EV batteries in the making.

Solid-state batteries have the potential to greatly improve electric vehicles.

- The demand for electric vehicles is increasing rapidly, and solid-state batteries are seen as the next step in battery technology

- These batteries use a solid electrolyte which allows for advanced electrode materials and higher energy storage capacity

- SCHOTT is working on glass-ceramic powders that can enhance the performance and stability of solid-state batteries, making them more viable for mass production and widespread use in the future

Dr. Nina Hoinkis centers her focus. Wearing four layers of thick laboratory gloves, she pushes her arms into the inert glovebox and carefully lifts a tiny scoop of delicate white powder from a plastic vial.

This might not be how movies depict groundbreaking, potentially world-changing research, but it’s exactly where she wants to be. For as long as she can remember, the material research project manager has always been drawn to chemistry.

“I think what fascinates me about chemistry, is that it can explain almost every phenomenon that surrounds you,” she explains. “If it’s in your body, in your kitchen, or in nature, chemistry provides you all the pieces – you just have to figure out how they fit together, kind of like a jigsaw puzzle.”

So, what jigsaw puzzle requires four pairs of safety gloves and a vacuum pump-maintained inert atmosphere? The next generation of e-mobility batteries.

Longer range, reduced charging times: An overdue upgrade to e-mobility battery technology

Transportation is one of the largest contributors to heat-trapping greenhouse gas emissions in the world. Particularly in the United States, fossil fuel-burning vehicles are responsible for the majority of those transportation-produced emissions. By eliminating tailpipe emissions altogether, electric vehicles have become a more efficient and sustainable alternative to those that would otherwise exacerbate climate change. Plus, as gas prices continue to rise, EVs stand as a wallet-friendly alternative as well.

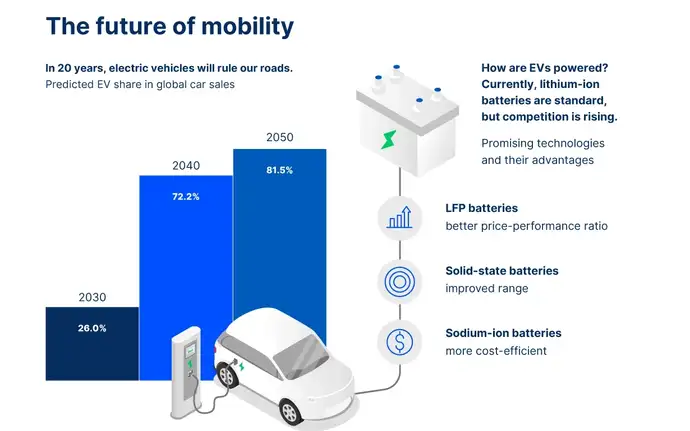

To that end, the fate of the combustion engine has been sealed. If that hasn’t become apparent over the past few years, it will soon. In 2011, there were roughly 55,000 electric vehicles sold around the world. Today, that number has ballooned to over 8 million EVs sold between January and August of 2023 alone. That means that it’s taken just over a decade for electric cars to make up almost 20% of all car sales around the world.

Impressive as that growth may be, however, 20% of global car sales is a long way away from 100%. And the planet’s ongoing climate crisis isn’t going to wait for that to happen. Those key components that lifted electric cars into their current position have become key impediments to increasing that market growth – and consequently, in reducing the climate impact of mobility as well.

That’s because today’s electric cars are, by and large, powered essentially by the same lithium-ion battery technology that Sony invented to power camcorders back in 1991. To be sure, that invention is the reason we have electric cars in the first place. But after more than thirty years of gradual improvement in the technology, these batteries are reaching the peak of their capabilities just as demand for electric vehicles begins growing exponentially.

Liquid lithium-ion batteries are manufactured using liquid electrolytes. However, advanced electrodes cannot be used together with liquid electrolytes, which limits the energy in one cell. In order to store more energy, you need more cells. The more cells in your battery, the bigger, heavier, and more expensive it becomes – which is a problem, when price, performance, and safety are critical to the transition away from fossil fuel-burning vehicles.

Simply put, electric vehicles have already squeezed every last ounce of energy from conventional lithium-ion batteries. “There will be no real revolution in liquid lithium-ion batteries, the clock is ticking on this technology,” says Dr. Andreas Roters, who is directing innovative battery research at SCHOTT. “Which leads to the next question – what comes next?”

The question began floating around back in 2011. "We saw energy storage becoming an important topic, and started thinking of ways our material research could contribute to overcoming the limits of standard batteries,” Andreas explains. “After plenty of research and analysis, we decided to start looking at solid-state batteries – even though hardly anyone in Europe or the US was talking about them at that point.”

History in the making

What is a solid-state battery? In short, solid-state batteries use a solid electrolyte, rather than a liquid, to transport the Lithium between the electrodes. Depending on its material, the solid electrolyte can enable advanced electrode materials and thus have a major impact on the energy storage capacity within a battery.

And though batteries might not be “the first thing that come to mind when you think of glass,” Andreas laughs, the company’s longstanding history of material expertise provided a unique edge in developing groundbreaking solid electrolyte materials.

What’s glass-ceramic’s job within a solid-state battery?

“We started asking, what material is really needed, and how can we adapt our material to this need?” Andreas recalls. “We knew that we could combine glass and ceramic materials in a way that allows us to customize and extract better properties.”

“Producing these materials via melting technology is considered very difficult. Thanks to our glass making heritage, I believe that SCHOTT is more or less the only company in the world with the experience, competency, and technologies to do it,” he explains. “So we eventually found a way to adapt existing melting technology to produce this groundbreaking new glass-ceramic powder.”

"Groundbreaking,” is putting it lightly. This ion-conducting, solid electrolyte in the form of white glass-ceramic powder boasts high conductivity, high chemical and temperature stability, and improved performance. Not only is the glass-ceramic extremely effective from a functional standpoint, but it’s also highly scalable and therefore cost-effective as well.

The material advantage of glass-ceramic

Utilizing solid electrolytes made of SCHOTT’s new glass-ceramic powder enables batteries to have several advantages over conventional batteries, Nina explains. “They’re non-flammable, they’re mechanically more stable, and most importantly,” she says, “chemically stable solid electrolytes allow you to change the anode material from graphite to lithium metal, which has ten times higher storage capacity.”

That higher storage capacity means solid-state batteries can store more energy in a smaller package compared to liquid lithium-ion batteries. At the same time, solid-state batteries don’t suffer the same “bottleneck” of charges that limits how quickly the batteries can charge. This is because the speed of ions moving between cathode and anode without causing damage to the battery is usually much lower in liquid-ion batteries with conventional anode material.

In terms of electric vehicles, “these improvements could enable electric cars to travel up to 30% further,” says Dr. Nicolas Brune, Senior Manager Business Development for New Ventures at SCHOTT. “And though we’re not there yet, charging up to 80% in 10-minutes seems feasible from where we’re at.”

From a safety standpoint, solid-state batteries would solve a lot of the very scary, very public problems plaguing today’s electric vehicles as well. Conventional lithium-ion batteries contain liquid electrolyte, which is an easy burning component. “And when the liquid electrolyte burns,” Andreas explains, “this is when the battery explodes, and it's really quite dangerous.”

To be sure, despite the publicity of such events, statistics show electric vehicle fires are significantly less common than those of their fossil fuel-burning counterparts.

Solid-state batteries can reduce the risk of fires even more, then, by simply “getting rid of the flammable things and replacing them by non-flammable solids,” Andreas says. This is where the unique properties of the new glass-ceramic powders stand out, making it particularly adept at withstanding high temperatures and improving the battery’s overall stability.

Solid-state batteries could very well provide the spark needed for mass-market adoption of electric vehicles. But there’s still a long road ahead. “They’re not going to replace liquid lithium-ion batteries today to tomorrow,” Andreas says. “But for now, we are continuing to improve our materials and are seeing growing demand overall.”

According to a study by French market research company Yole Développement, mass production of solid-state battery equipped vehicles could start in 2030. And when that happens, Andreas is convinced that the white glass-ceramic powder will be there.

In the meantime, SCHOTT has collaborated with a global network of partners with contacts to leading automobile manufacturers and cell producers, including two pioneering grant funded development projects. One of which is the European Union-funded SAFELiMOVE project, which is renowned among automotive, cell, and material manufacturers, and aims to research hybrid cell systems for electric vehicles.

Solving the puzzle

Tomorrow’s fast-charging, long-lasting electric vehicles are the result of today’s steppingstone-breakthroughs and endless reels of data. For all her pragmatism, Nina’s jigsaw puzzle approach to the world requires a healthy dose of optimism as well. Optimism not only in the belief that any problem can be solved, but in pursuing the bigger picture – even when the puzzle pieces are tangled and strewn across the kitchen table.

Once more, Nina is unfazed. “When you work in a lab for such a long time, even the tiniest results will make you happy – your heart beats faster, you don’t believe the great results at first, you double-check them, triple-check them, and you discuss with colleagues,” she says. “Then, you’re filled with happiness.”

So, for all the potential challenges that might lie ahead, and progress needed to be made, Nina is convinced it’s only a matter of time. “The breakthrough of solid-state batteries will come,” she says, it just takes one puzzle piece at a time.