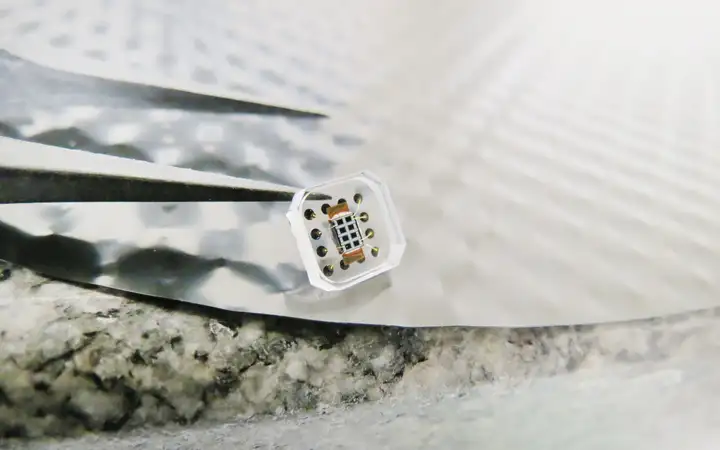

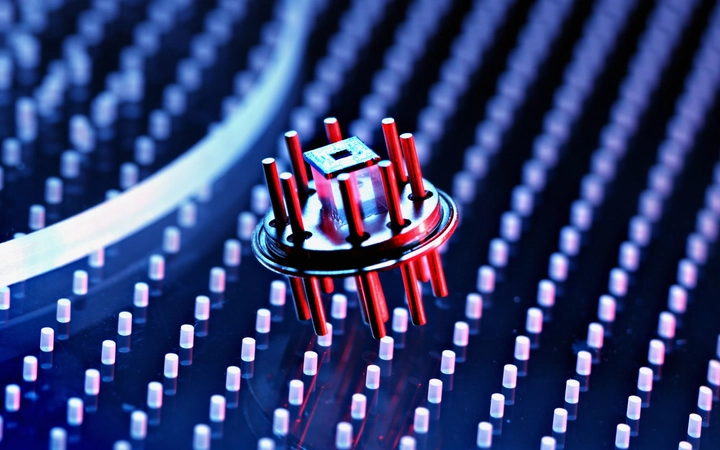

MEMS

Micro-electrical mechanical systems (MEMS) continue to grow in importance across a wide variety of industries. Their delicate microscopic components need power, I/O interconnects and reliable protection, so SCHOTT offers a range of highly robust, precise and miniature packaging components and materials.