Technical Details of SCHOTT® Cavity Cap

Accurate, reliable, and highly customizable

Technical Details for SCHOTT

| Material | D 263® Family | MEMpax® | AF 32® eco | BOROFLOAT® 33 |

|---|---|---|---|---|

| CTE (ppm/K) | 7.2 | 3.3 | 3.2 | 3.3 |

| Technical Data – Window |

|

|---|---|

| Luminous transmittance τvD65 at 0.3 mm | ~ 91.7 % |

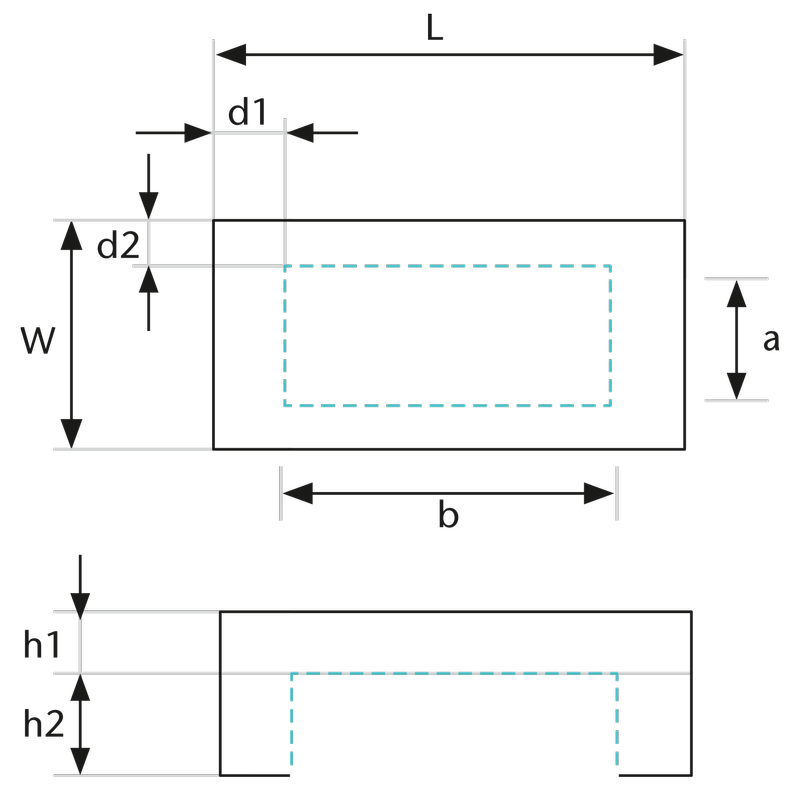

| Thickness (h1) | 0.1 – 1.1 mm |

| AR coating (single-side/double-side) | on demand |

| Technical Data – Spacer |

|

|---|---|

| Spacer height (h2) |

0.2 – 3.3 mm |

| Opening size (a, b) | variable; min. 0.3 mm |

| Opening tolerances | < 20 μm (equiv. ± 10 μm) |

| Dam width (d1, d2) | down to 0.5 mm |

| Technical Data – Cap | |

|---|---|

| Cap size (L, W) | variable; min. 3 x 3 mm |

| Cap size tolerance | ± 100 μm |

| Cap height (h1+h2) | min. 0.3 mm |

| Chipping (inner edge) | < 10 μm |

| Chipping (diced outer edge) | < 100 μm |

Bonding

-

Wafer-level hermetic laser bonding: high level of hermeticity.

-

Minimal heat load: heat-affected zone of just a few micrometers.

-

Additive-free: no adhesives or extra materials required.

SCHOTT® Cavity Cap Materials

SCHOTT® Cavity Cap is available as:

-

D 263® T eco

-

AF 32® eco

-

MEMpax®

-

BOROFLOAT®

To find out more, please see the related materials on the overview page.