Product Variants of Infrared Glasses and Materials

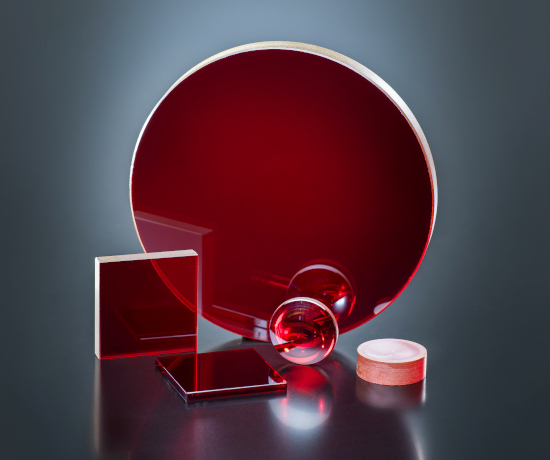

Infrared Chalcogenide Glasses (IRG 22 – 27)

CHARACTERISTICS

The infrared glass series offered by SCHOTT can also be processed using conventional grinding and polishing techniques, as well as single point diamond turning or molding to support low- to high-volume manufacture.

YOUR ADVANTAGES

- Low dn/dt and dispersion, with high color correction

- Low Tg so moldable for high volume production.

- Lower density than established infrared materials e.g. Germanium.

- Lower price than established infrared materials.

- Conventional processing, meaning no constrains for grinding, polishing and diamond turning.

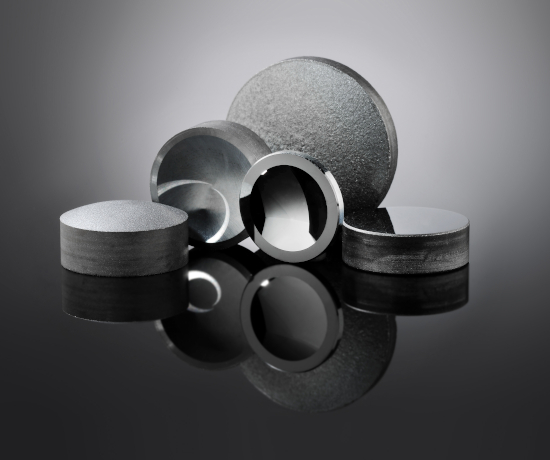

Sapphire for Advanced Imaging

CHARACTERISTICS

With years of experience in infrared glass, SCHOTT can offer sapphire in a wide range of processed shapes according to customer specifications, along with the availability of polished surfaces and customized coatings.

YOUR ADVANTAGES

- Extreme hardness and high mechanical strength.

- High transmission from UV to IR.

- Various shapes from round to square available, and up to 300 mm in diameter.

- SCHOTT uses advanced equipment and state-of-the-art metrology for manufacturing and quality control.

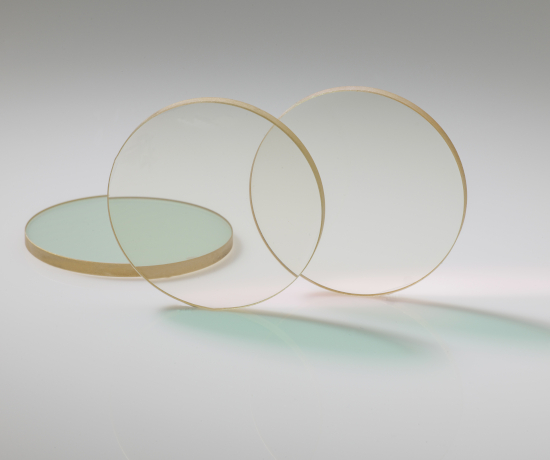

Anti-reflective hard coating on Multispectral Zinc Sulfide

CHARACTERISTICS

- Low reflectance and absorption.

- Highly scratch-resistant surface.

- Customized coating for every wavelength band.

- European production.