Solid Oxide Electrolyzer Cells (SOEC)

Could glass be the key to life on Mars?

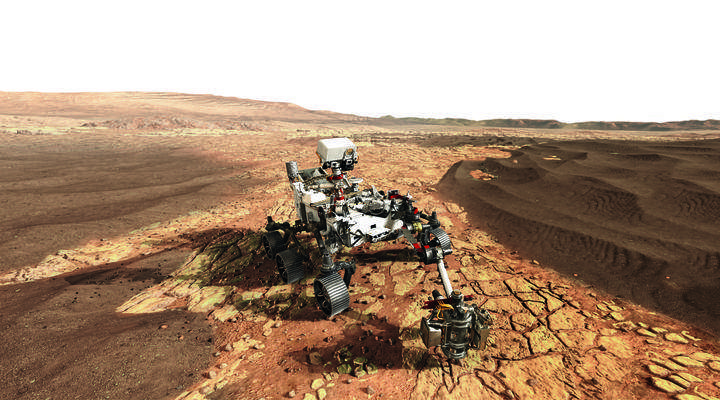

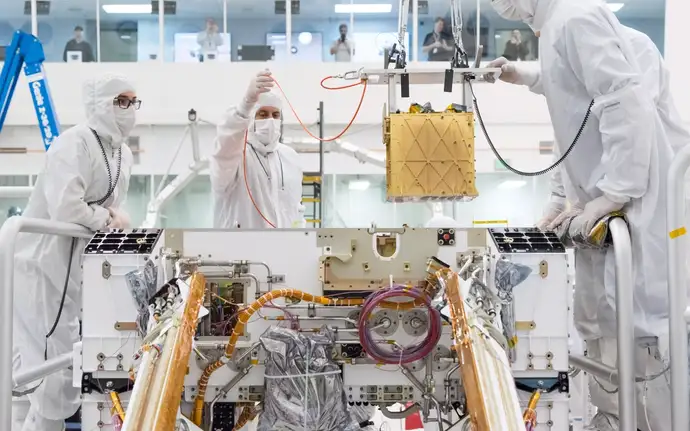

Is life possible on other planets? The US space agency NASA has sent its rover Perseverance to Mars in July 2020 in an effort to answer this question. Perseverance landed on Mars in February 2021 with seven unique instruments aboard. They will help to explore the planet better than ever before. One of the most exciting is the MOXIE (“Mars Oxygen ISRU Experiment”, with ISRU standing for “In-Situ Resource Utilization”). The experiment attempts to extract oxygen from the carbon dioxide of the Mars atmosphere by electrolysis for the first time. MOXIE uses a solid oxide electrolysis (SOXE) stack developed by the US company OXEon Energy. On its journey through space, the stack is exposed to extreme conditions: it must not only withstand the vibrations of the rocket launch and the landing impact, but also function in temperatures ranging from -55 °C to over 800 °C. To maintain the high efficiency of the stack over the duration of the mission, OXEon utilizes special glass-ceramic sealants from SCHOTT.

How MOXIE works

MOXIE uses a solid oxide electrolysis (SOXE) stack for converting CO2 to O2, developed by OXEon Energy. Its working elements consist of stacked electrolyte-supported cells that are coated with a cathode on one side and an anode on the other. Interconnected plates separate and direct the gases through the stack. These plates are sealed by SCHOTT’s highly temperature-resistant and leak-tight glass-ceramic.

When CO2 flows over the cathode under an applied electrical potential, a reaction occurs and it is electrolyzed. The CO is exhausted and the oxygen ion is electrochemically driven through the SOXE to the anode where it is oxidized. The O-atoms combine to produce O2.

Glass seals join electrolysis stacks with secure hermetic bonds

During production of the SOXE stack, the glass powder is melted to form a bond between the ceramic electrolyte and metal interconnect of the cell. The sealing glass is formulated to match the exact coefficient of thermal expansion of the metals and ceramics, creating an uncompromising hermetic seal that remains stable even when temperatures shift. Furthermore, the interconnectors of the cells that are switched in series as part of a stack, are electrically insulated by the alkaline-free glass, even at high temperatures.

“The extreme temperatures and high forces present a special challenge for the MOXIE,” explains Dr. Jens Suffner, Technical Sales Manager at SCHOTT Electronic Packaging. “Many types of glass turn soft and elastic at temperatures of 500 °C and higher.” To prevent this, SCHOTT uses special sealing glasses with defined crystalline phases. This keeps the glass seal gas-tight and in place with sufficient strength, even under the harsh conditions present on Mars.

With MOXIE being successful, it might revolutionize human exploration on Mars. The breathable air needed for a manned space mission could be directly generated on site. The created oxygen will also be used as the oxidant for the production of rocket fuel. This would solve an essential part of the challenge for enabling a return flight. So far, the road to the red planet has been viewed as a one-way street.