High-heat-dissipation hermetic laser packages with copper heat sinks

Superior thermal management for high-power lasers

Design flexibility for advanced laser architectures

SCHOTT enables engineers to tailor packages to their specific optical and thermal requirements:

- Copper heat sinks or heat slugs brazed to TO bases or integrated into rectangular packages

- Customizable copper geometries optimized for thermal distribution

- Option for SMD-style hermetic packages for compact, board-level integration

- Custom support for multi-laser modules, stacked emitters, and high-density laser designs with in-house thermal simulation capabilities.

TO-9 hermetic headers with copper heat sink

The TO-9 hermetic header with a copper heat sink is engineered for high-power laser systems requiring highly efficient thermal extraction and mechanical precision. Suitable for blue, green, red, and violet high-power laser diodes. TO-9 copper headers are potential to be the cost-efficient alternatives to box packages.

Key advantages:

- Thermal resistance (Rth) of approx. 8 K/W (thermal simulation including laser, submount & header)

- High surface flatness accuracy for optimal thermal interface

- Ideal for projection systems, automotive HUD lasers, laser marking, and industrial high-power modules

- Available with customized geometries, extended copper platforms, or multi-laser configurations

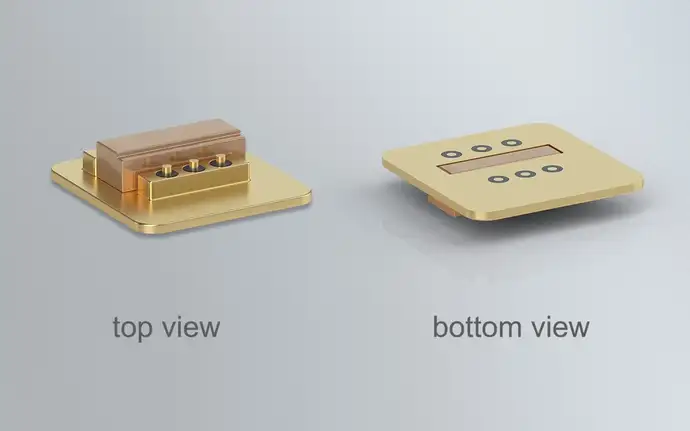

Copper heat-sink SMD hermetic packages

SCHOTT’s hermetic SMD packages with copper heat sinks provide excellent thermal performance in compact footprints.

Benefits include:

- Highly efficient copper-based heat dissipation

- Low-profile SMD formats for compact module integration

- Custom pin layouts, window materials, and copper configurations

- Suitable for VCSEL arrays, edge-emitter lasers, and multi-emitter modules

Typical applications

- Laser marking & engraving

- High-power projection and display systems

- Automotive laser headlights & HUD modules

- Industrial sensing & metrology lasers

- Medical and scientific high-power laser devices

Why high-power laser manufacturers choose SCHOTT

- 80+ years of expertise in hermetic glass-to-metal sealing (GTMS) technologies

- Proven capability for copper integration in laser packages

- High-precision production of TO headers and SMD hermetic packages

- Global production footprint ensuring supply reliability

- Engineering support for custom high-power laser module design

- SCHOTT enables the development of more powerful, more stable, and longer-lasting high-power laser systems.

To find out more about what makes SCHOTT the preferred hermetic packaging supplier, read more here.

Frequently Asked Questions (FAQ)

Robert Hettler

Head of R&D Opto-electronics