Applications of Sealing and Solder Glass Frits

SCHOTT sealing glasses perform with reliable efficiency in a range of industrial operations, including fuel cells, batteries, vehicle combustion systems, electrical equipment, and components in the chemical and nuclear sectors. Solder glasses are used in MEMS packaging, opto-electronics, and display device sealing.

Corrosive Environments

Low-Temperature Joining

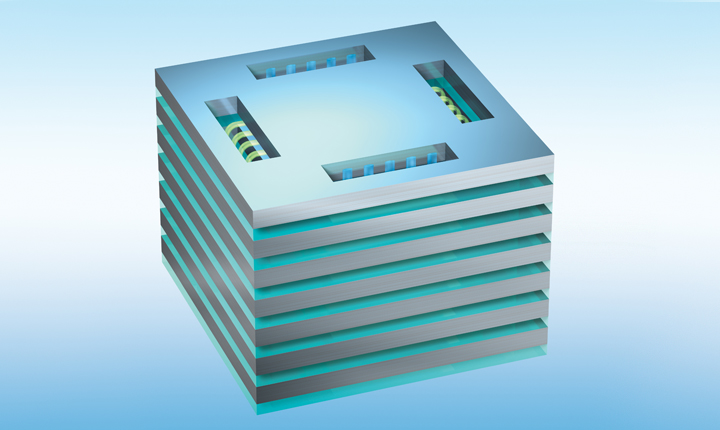

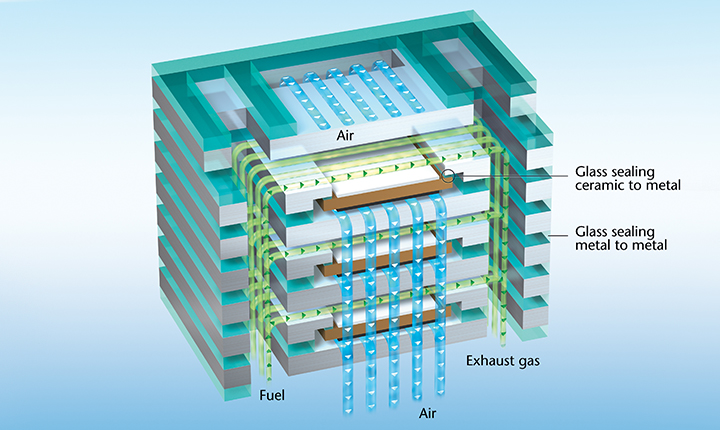

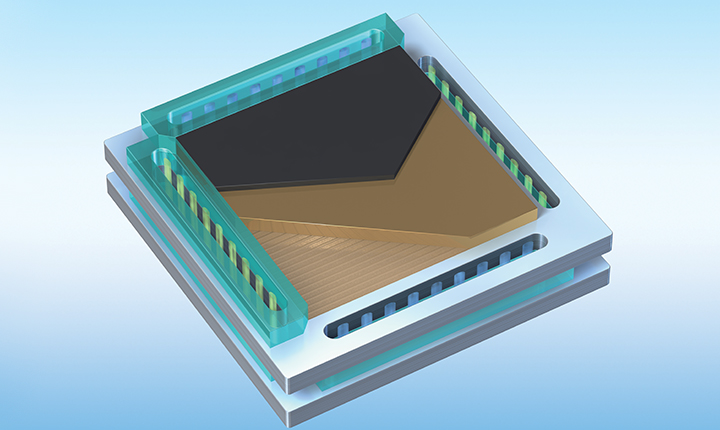

Solid Oxide Fuel Cells (SOFC) and Electrolyzer Cells (SOEC)

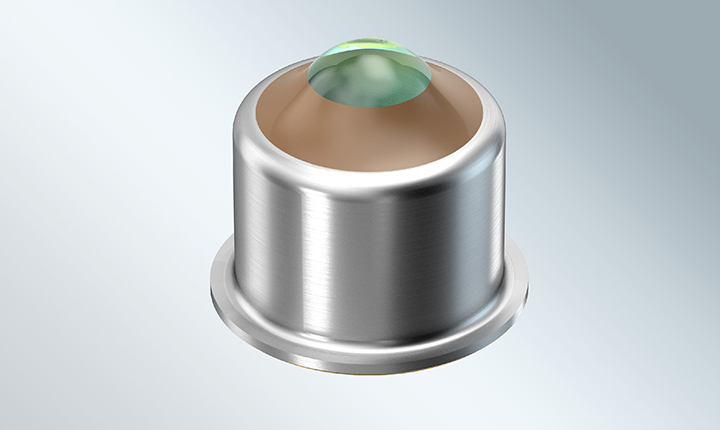

Sensor Technology

Antonio Trizzino

Sales Manager Europe