SCHOTT launches high-performance cover glass for next-generation space solar cells

Tuesday, 18 November, 2025, Mainz, Germany

- SCHOTT® Solar Glass exos provides enhanced radiation resistance and optical performance for simple silicon cells up to III-V multijunction satellite solar cells.

- Jointly developed with Heilbronn-based AZUR SPACE Solar Power GmbH, SCHOTT’s new cover glass was supported by funding from the European Space Agency (ESA).

- Engineered for use in both space agency missions and satellite constellations, this fully certified solar cell cover glass delivers high scalability and cost efficiency.

SCHOTT, a global leader in specialty glass and advanced materials, today announced the launch of SCHOTT® Solar Glass exos, an innovative solar cell cover glass designed for next-generation space missions. Developed with funding from the European Space Agency (ESA) and supported by the German Aerospace Center (DLR), exos was developed together with AZUR SPACE Solar Power (a 5N Plus company), Europe’s leading developer of multi-junction solar cells, which also conducted testing and initial validation. The new solar cell cover glass is engineered to deliver optical stability, thermal compatibility, and broad scalability for advanced satellite applications. The exos collaboration combines SCHOTT’s materials expertise with AZUR SPACE’s technology leadership to deliver a cover glass compatible with a wide range of solar cell types, from silicon cells to advanced III-V multijunction solar cells, which are the industry standard for modern satellites.

Protecting Power in Space

Every space mission relies on solar cells to power satellites and spacecraft. But space is an unforgiving environment: intense radiation, rapid temperature fluctuations, and the demand for uninterrupted performance push conventional cover glasses to their limits. Ensuring that solar cells remain efficient for long missions requires an innovative protective solution.

SCHOTT® Solar Glass exos features an advanced design for long-term performance in demanding space environments. Its optimized composition provides exceptional UV absorption and optical stability, maintaining reliable protection and high transmission even after extended radiation exposure. The glass is highly resistant to solarization, with transmission characteristics that remain virtually unchanged over time — a key advantage for ensuring consistent efficiency in satellite solar cells and optical assemblies. Additionally, the precisely tuned UV transmittance edge of SCHOTT® Solar Glass exos allows manufacturers to fine-tune UV protection by selecting the appropriate glass thickness. This controlled cutoff design shields underlying adhesives and sensitive materials from premature UV exposure, enhancing durability and long-term bonding stability.

With a coefficient of thermal expansion (CTE) of 6.9 × 10⁻⁶ K⁻¹ precisely matched to GaAs solar cells, exos minimizes mechanical stress and enhances structural integrity under thermal cycling. Available in scalable formats and customizable thicknesses, it has been engineered to meet demanding mission profiles across LEO, MEO, and GEO orbits. The cerium-doped material is undergoing qualification in accordance with European Cooperation for Space Standardization (ECSS) standards.

The partnership between SCHOTT and AZUR SPACE highlights Europe’s drive to advance space materials innovation and build a resilient, scalable supply chain for the rapidly expanding satellite industry. “Our collaboration with AZUR SPACE demonstrates how close cooperation can deliver space-qualified solutions at scale,” said Marc Schneider, Head of SCHOTT’s Special Applications Product Group. “As we expect that the demand for satellite constellations will continue to expand, we’re excited to provide the industry with a reliable, high-performance solar cell cover glass to help power missions in every orbit.” AZUR SPACE noted that the collaboration marks a critical step toward establishing a resilient supply chain for next-generation satellite power systems. “AZUR SPACE is proud to work with SCHOTT to secure a stable and large-scale, 100% European supply chain for solar cell assemblies,” said Executive Vice President Specialty Semiconductors, Roland Dubois, head of AZUR SPACE. “This collaboration strengthens Europe’s technological independence and ensures the reliable availability of high-performance solar power solutions for future space missions.”

Learn more about the SCHOTT x AZUR SPACE collaboration.

SCHOTT® Solar Glass exos is a registered trademark of SCHOTT AG.

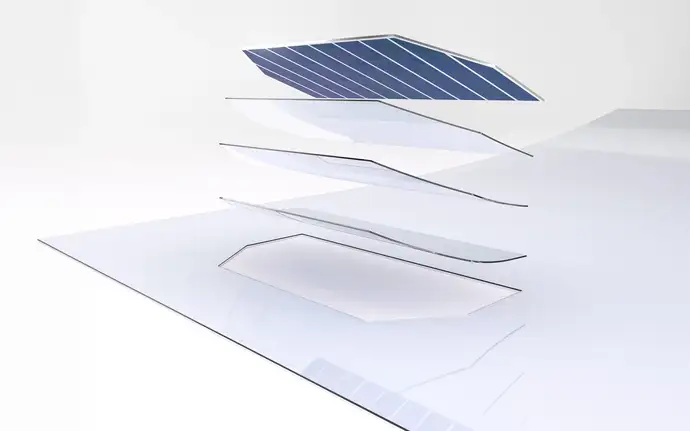

SCHOTT’s new solar cell cover glass is engineered to deliver optical stability, thermal compatibility, and broad scalability for advanced satellite applications. Photo: SCHOTT

Jointly developed with AZUR SPACE Solar Power GmbH, SCHOTT’s new cover glass was supported with funding from the European Space Agency (ESA). Photo: SCHOTT

Even after intense UV exposure, SCHOTT® Solar Glass exos retains its high transparency and optical stability, a key advantage for reliable performance in demanding space environments. Graph: SCHOTT

About SCHOTT

International technology group SCHOTT produces high-quality components and advanced materials, including specialty glass, glass-ceramics, and polymers. Many SCHOTT products have high-tech applications that push technological boundaries, such as flexible glass in foldable smartphones, glass-ceramic mirror substrates in the world's largest telescopes, and laser glass in nuclear fusion. With their pioneering spirit, SCHOTT’s 17,400 employees in over 30 countries work as partners to industries such as healthcare, home appliances, consumer electronics, semiconductors, optics, astronomy, energy, and aerospace. In fiscal year 2024, SCHOTT generated 2.8 billion euros in sales. In addition to innovation, one of its important corporate goals is sustainability,. SCHOTT was founded in 1884 and is headquartered in Mainz, Germany. The company belongs to the Carl Zeiss Foundation, which uses its dividends to promote science. Further information at SCHOTT.com

Elisabeth Harvey

PR & Communications Manager