Product Variants of Laser Glasses and Components

The laser glass product portfolio that SCHOTT offers can cover the whole spectrum of active and passive laser glasses. We divide our laser glasses into three main product variants so that our customers can focus on the glass that is best suited for their application.

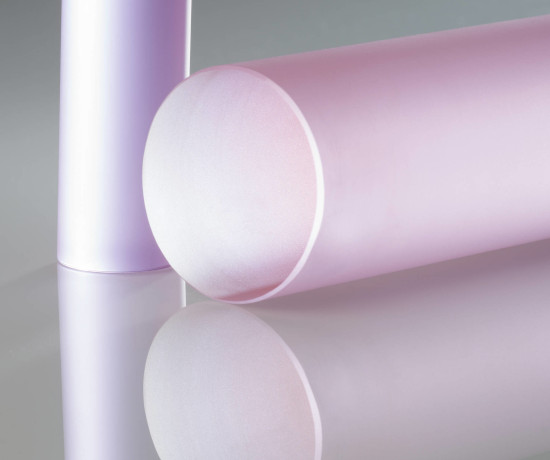

1 µm Silicate and Phosphate-based Laser Glass

CHARACTERISTICS

These include large volume laser glass slabs in apertures up to 400 mm and in large quantities, which enable high-energy storage for inertial confinement fusion programs. They are also suited to zig-zag slabs and large diameter laser rods with the highest optical quality and homogeneity possible, which can help facilitate high-output power of materials processing laser systems.

YOUR ADVANTAGES

- High laser cross section

- Low nonlinear refractive index

- Athermal characteristics

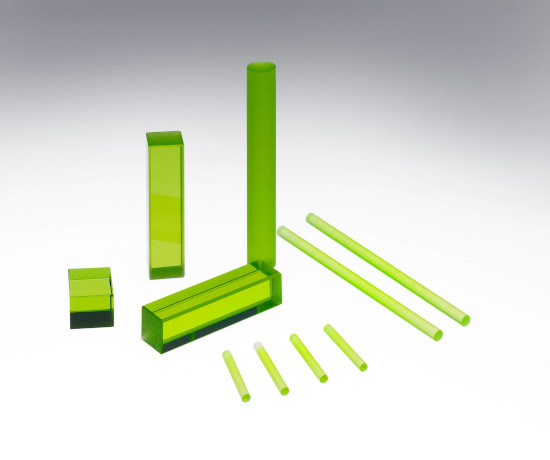

Eye-safe 1.5 µm Phosphate Laser Glass

CHARACTERISTICS

Phosphate laser glasses generally offer higher solubility of rare earth dopants, meaning that the amount of active ions can be significantly increased. Examples of glasses in this group are LG-940 Erbium-Ytterbium-Chromium-Cerium doped glass, LG-950 Erbium-Ytterbium doped phosphate laser glass (produced specially for the European market) and LG-960 Erbium-Ytterbium doped phosphate laser glass, which offers an improved thermomechanical figure of merit.

YOUR ADVANTAGES

- Suited to cost-effective solid-state laser systems.

- Potential for increased load and/or repetition rates.