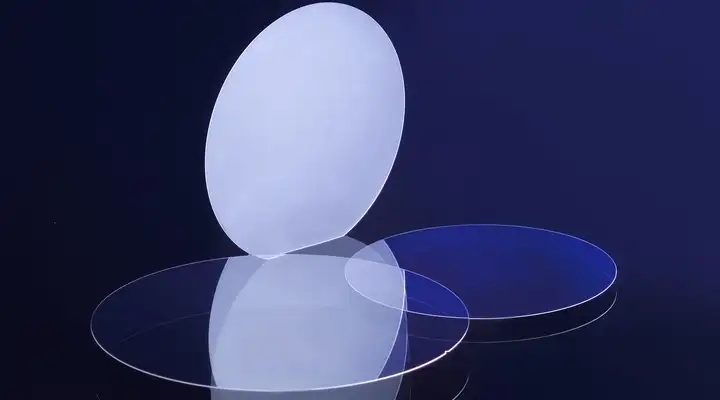

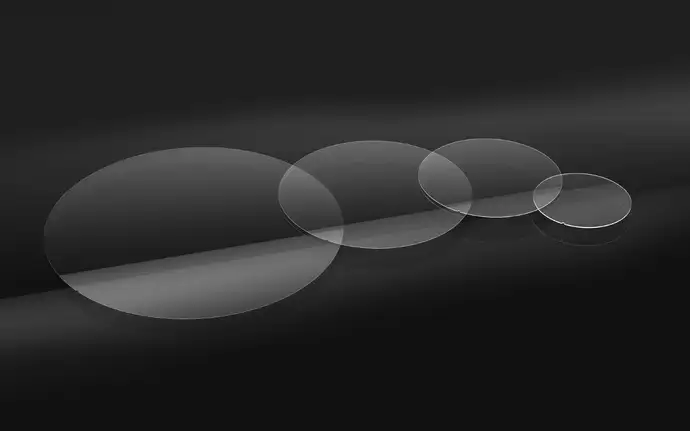

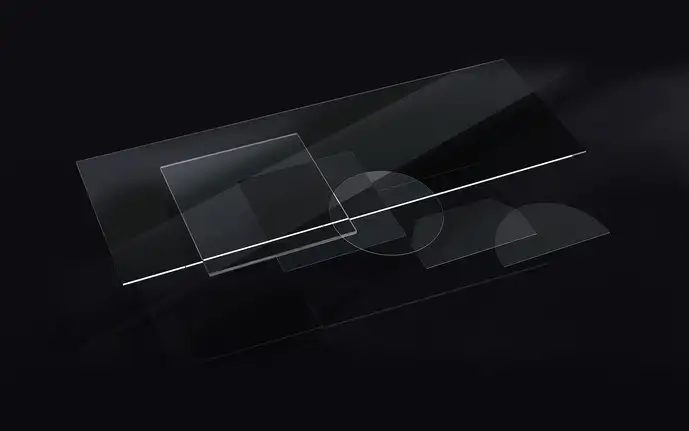

Substrates and Wafers

Tight geometric tolerances, no matter the thickness

Multiple glass types with a broad CTE range

Wide choice of options delivers the ideal solution

SCHOTT’s glass substrate and wafer range is built on technical excellence proven in rigorous tests. We have access to a broad range of materials, as well as advanced processing and manufacturing technologies, resulting in high-performance wafers and substrates with a wide spectrum of CTEs and the option of achieving TTVs of less than 0.6 µm. Further benefits include a range of thicknesses, tight geometric and surface tolerances, and semiconductor-ready laser marking and packaging if required.

We are certified

We are both ISO 9001 and 14001 certified. The production of our substrates and wafers is constantly monitored at all stages, and they also comply with EU-RoHS and EU-REACH standards.

Related products

Want to know more? Let’s talk

Whether you need more information, samples, a quote, or advice for a project, we would be delighted to talk to you.

Contact us