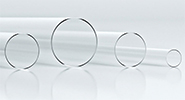

perfeXion® - a zero defect approach

High-end quality processing

Traditionally, quality control for glass tubing is based on assessing random samples, but SCHOTT perfeXion® brings the process into the 21st Century. PerfeXion® provides highly accurate monitoring of glass tubing, not just for random samples, but for every single tube.

As the tubing travels down the production line, cameras measure parameters such as the diameters of the tubes, wall thickness, and airlines, as well as imperfections. If a single section of tubing isn’t perfect, it’s rejected. A data management system also gathers and analyzes data to enable customization. The result is less defects, superior cosmetic quality, and improved performance.

SCHOTT perfeXion® revolutionizes the inspection of glass tubing

The high-precision geometry and superior visual quality of 100 % inspected tubing results in significantly improved container performance.

Intelligent assessment

Dr. Claudia Heinl

SCHOTT Senior Product Manager Pharmaceutical Tubing