Precision injection molding solutions

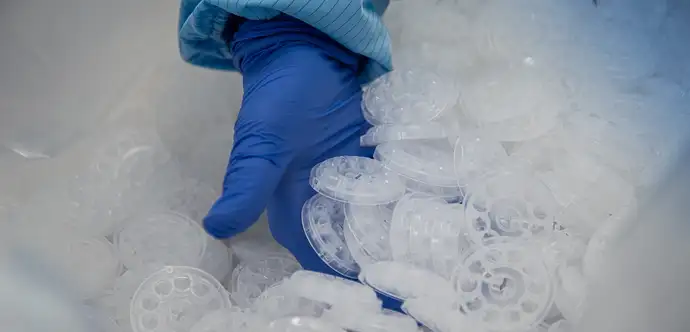

SCHOTT MINIFAB is a global leader in precision injection molding. We excel at delivering parts with precision features and tight tolerances. We focus on high-volume products for regulated markets where quality is non-negotiable.

Exacting standards in precision injection molding

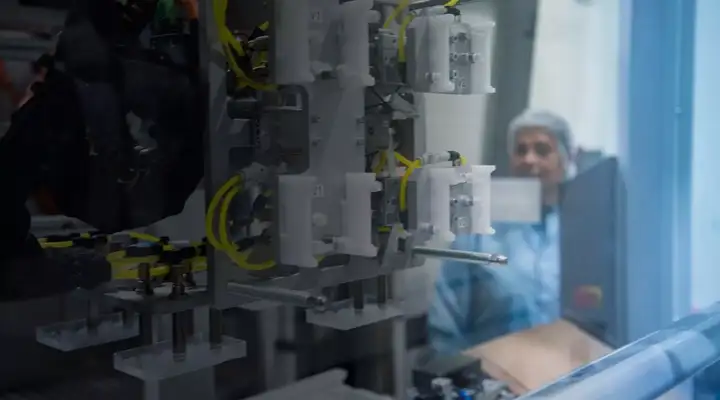

We excel in providing comprehensive injection molding solutions tailored to your exact needs. With a state-of-the-art facility equipped with precision tooling capabilities and advanced automated equipment, we offer a diverse range of molding technologies to bring your vision to life. Our extensive array of material options ensures that we can meet most project requirements. Operating within certified ISO 9001, ISO 13485, and Laminar flow controlled clean environments, we not only meet industry standards but exceed them, guaranteeing the utmost quality for your end product.

Design for injection molding

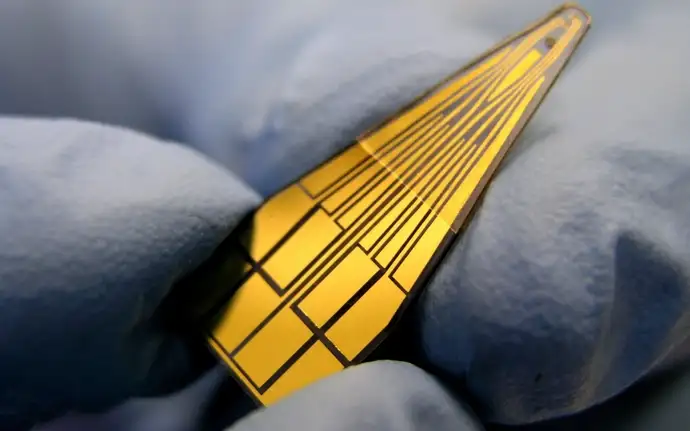

In-House tooling

High quality tooling ensures the precise and consistent production of molded parts. Our in-house team of tooling experts specializes in injection molding design, mold flow analysis and tooling for microfluidic applications. Using advanced tooling technologies, the tooling team can develop molds with complex geometries, tight tolerances, and intricate designs, specifically for industries that demand a high degree of quality and precision.

Tailored molding solutions

We understand that achieving optimal product performance begins with selecting the right molding technique early in the design phase. At SCHOTT MINIFAB, we ensure that our clients have access to the precise tools needed to bring their innovative designs to life. From standard to precision, vario-thermal, and 2K injection molding, we offer a diverse suite of molding technologies, chosen to address specific project requirements. Explore our table below for a comparison of features across different molding techniques.

|

Parameter |

Standard injection molding |

Precision injection molding |

Variothermal injection molding |

2K injection molding |

|---|---|---|---|---|

|

Tolerance and precision |

Moderate |

High |

High |

High |

|

Material compatibility |

Thermoplastic (single material) |

Thermoplastic (single material) |

Thermoplastic (single material) |

Thermoplastic, Elasomeric (multi material) |

|

Cycle time |

Standard |

Standard |

Longer |

Longer |

|

Cost |

Economical |

Moderate to high |

Moderate to high |

Moderate to high |

|

Part complexity |

Moderate |

High |

Very high |

High |

|

Surface finish |

Standard |

High |

High |

High |

|

Tooling complexity and maintenance |

Low to moderate |

Moderate to high |

Moderate to high |

Moderate to high |

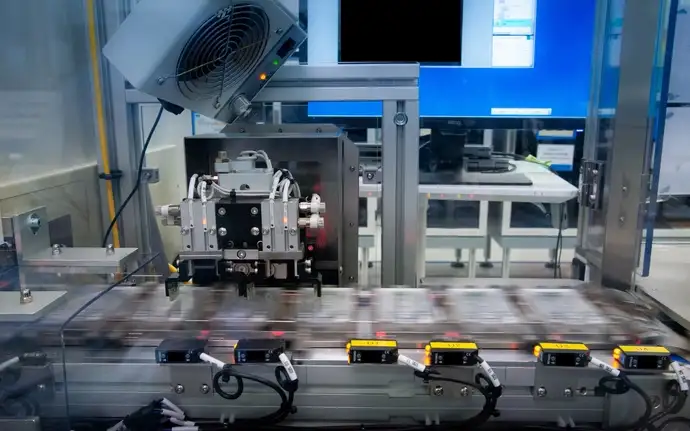

Molding infrastructure

Our advanced infrastructure redefines industry standards, with robust capacity, stringent certifications, and precision-driven automation for unparalleled efficiency and consistency in injection molding.

Material experts

We offer a wide array of materials for your injection molding needs:

- Polycarbonates (PC)

- Polymethyl Methacrylate (PMMA)

- Polypropylene (PP)

- Cyclic Olefin Copolymer (COC)

- Cyclo Olefin Polymer (COP)

- Thermoplastic elastomers (TPE) with 2K Compatibility

- Styrene-ethylene-butylene-styrene (SEBS)

- ...and more, if you have a specific need let's discuss.

Proven partnership

Whether you’re a startup or an established industry leader, we are your trusted partner with decades of proven experience. You can rely on us to meet and exceed your expectations.

Contact us for your injection molding needs

Choose SCHOTT MINIFAB for precision injection molding, without compromise. Request a quote or kick off your project by consulting with one of our engineering experts.