Optical materials and laser glass from SCHOTT: The "heart" of nuclear fusion research

Pioneering what seemed impossible: Recreating the sun

The sun and stars in our galaxy are churning with fusion reactions. An infinite amount of hydrogen atoms is constantly colliding, smashing atomic nuclei into one another with such force that they combine and, as a result, release energy in the form of light and warmth. Being able to recreate and control such a reaction here on Earth would mean unlocking a source of energy that neither relies on fossil fuels, nor produces the greenhouse gasses or radioactive waste that decimate the planet.

Unfortunately, recreating the power of the sun isn’t as easy as it might sound.

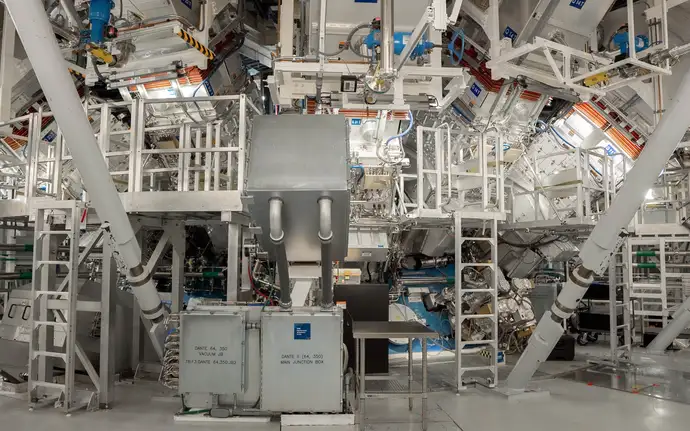

The world's biggest laser system, powered by SCHOTT materials:

Background

Unleashing the world’s largest laser system onto a small pellet of hydrogen with such force that subatomic particles collide, and fuse together requires a massive amount of energy. And for decades, researchers fell short of creating a nuclear fusion reaction that produced more energy than it consumed – a threshold they call “ignition.”

Outside the experiment itself, the NIF scientists faced a logistical challenge. Each time the high-energy laser beams collided with their target; the resulting explosion sent dangerous debris in every direction. This caused enough damage to limit how often they could run the experiment, and thus became a major impediment to progress.

Task

Researchers at the NIF had two problems. First, they needed a unique material that could not only withstand massive amounts of energy, but direct, filter, and even amplify the laser power along the way. This would allow them to keep the initial amount of energy needed to fire the lasers low, improving the probability of ignition.Second, they needed blast-shields that could protect the laboratory’s fine-tuned equipment from being damaged every time an experiment was conducted. And if they wanted to run experiments more frequently, they needed those shields to be cost-effective and quick to manufacture.

Solution

With nearly 140 years of hardware and material expertise, SCHOTT worked closely with researchers at the NIF to understand how changes in glass composition can uniquely affect laser properties and mechanical operations. This close cooperation led to the development of an entirely new glass composition in accordance with the NIF’s unique specifications and allowed SCHOTT to pioneer a new, exponentially more efficient manufacturing process that enabled the NIF to run more experiments than ever before.

A synthesis of unique specialty glass enables research at the NIF

Specialty glass sealing:

Able to form tight and durable bonds, SCHOTT’s expertise in glass sealing helped the NIF implement sealing glass rods that are not only resistant to high temperature environments and resilient against thermal shock but provide outstanding light transmission as well.

BOROFLOAT® glass:

Tough, light and versatile, BOROFLOAT® – a floated low thermal expansion borosilicate glass – survives the harshest environments while maintaining superior transparency. Thus, it is the perfect material to shield the NIF's finetuned equipment from debris.

Polarizers, turning mirror substrates, flashlamps, laser slabs and more:

SCHOTT's continuous melting tanks and single batch crucibles allowed the production of custom glass components tailored to countless specific applications. For the NIF, SCHOTT manufactured more than 4,000 specific components to meet NIF’s unique requirements.

How SCHOTT glass amplifies and guides laser energy to facilitate nuclear ignition

A laser pulse that is only a few billionths of a joule, is carried on optical fibers to 48 pre-amplifiers of neodymium glass, which enhance the initial laser’s energy several billion times and define its shape. Laser mirrors and lenses guide the beam through two larger amplifiers made of laser glass. Thanks to specialty optics, the laser light repeats this four times – all while mirrors, filters, and other devices utilize specialty glass to form a beam that is uniform, high quality, and smooth.

Just before hitting the target, the beams travel through the final set of optics that convert 4 million joules of infrared energy into 2 million joules of ultraviolet energy, a shorter wavelength that is better for ignition. That ultraviolet energy collides with the target, compressing the hydrogen fuel to 100 times the density of lead and creating temperatures more than 100,000,000°C – for a mere fraction of a second, the NIF is the hottest place in our solar system.

What was once believed to be impossible is now a reality – and that is just the beginning.

What makes laser glass the key to nuclear fusion?

Glass has unique technical properties, such as material homogeneity, that make it an ideal host material for the rare-earth ions that give optically-pumped lasers their power. The level of homogeneity and refractive index range determine the quality of an optical material – and SCHOTT is able to tweak and alter those qualities in a range of active laser glass products and components that can be tailored to fit the very unique and highly technical, optical and industrial needs, to exactly what the NIF needed for their laser.

The enduring resilience of BOROFLOAT® glass

SCHOTT’s floated borosilicate glass protects NIF’s valuable optics from debris. BOROFLOAT ® is not only exceptionally transparent, it is also mechanically, thermally, and chemically resilient – hence the perfect material to shield NIF’s optics from harmful debris during the laser shots. SCHOTT’s proprietary microfloat production process provides a material with excellent surface quality and BOROFLOAT®’s outstanding abrasion- and scratch-resistant qualities, ensure that the glass performs even in the most demanding industrial environments.

Manufacturability: The Bottom Line

There is no doubt that highly technical expertise in material science and engineering was critical to developing the laser glass that helped the NIF achieve ignition. But without an equally proficient expertise in glass manufacturing and production, that specialty glass would only go so far.

At its Duryea, Pennsylvania facility, SCHOTT optics experts pioneered a continuous melting process to create larger slabs of glass that could be cut into smaller pieces. Where previous processes only yielded one substrate per day, this new melting process resulted in a higher yield, thus enabling the NIF to increase the frequency of experiments.

Bill James

Vice President Research & Development SCHOTT North America