Reliable connections for electric compressors in EV car air conditioners

The trend toward electromobility means that air conditioning compressors are increasingly being operated electrically. The operating voltages and therefore the requirements for the power supply terminals differ considerably. SCHOTT has developed optimum electric compressor feedthroughs for both high voltage and 48 V. Copper conductors for high current and additional insulation by means of a special synthetic elastomer for high-voltage applications are unique.

Air conditioning is now a standard feature of cars. Even in Europe, with its very different climate zones, the proportion of vehicles coming off the production lines with air-conditioning is around 92 percent, while in the USA it is virtually 100 percent. Experts expect high growth rates in India, for example.

Supporting the optimal driving experience

Comfort is not the only role filled by vehicle air conditioning. Studies have shown that road safety is at great risk if drivers suffer from temperatures beyond the 30-degree mark. Aircon systems also protect the driver and passengers from certain air pollutants because substances such as dust are removed together with humidity.

Electromobility presents new challenges for air conditioning. One reason is that in certain situations the lithium-ion batteries used to power the vehicles also have to be cooled because high temperatures reduce the lifetime of these batteries. They operate at their maximum efficiency between 15 and 35 degrees Celsius. Above this temperature the aging process speeds up. Several technological approaches are used to reduce the operating temperature. This is known as battery conditioning, and the most common way to achieve this is to use the aircon system itself as it is already installed in the vehicle. The usual cooling source is a compressor.

High voltage and 48 V

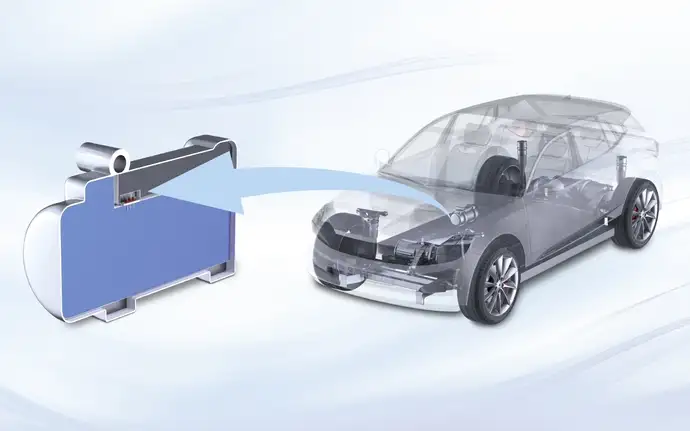

In an all-electric vehicle, the compressor must also be operated electrically. The same applies, of course, to hybrid vehicles so they can travel long distances under electric power. Otherwise, air conditioning of the passenger cell and conditioning of the drive battery would no longer be guaranteed in this operating mode. Currently (2020), seven percent of new vehicles delivered worldwide are equipped with an electric compressor. The majority feature a high-voltage supply. 48 V systems are still rare, but are gaining in importance. In both cases, the drive motor is integrated in the compressor. In contrast, in conventional vehicles the internal combustion engine drives the compressor via a belt. In the case of an electric compressor, energy has to be fed directly into the housing. This is achieved using appropriate feedthroughs. They are critical components for which SCHOTT is the leading supplier.

Demands on insulation

In high-voltage systems, the operating voltage available from the drive battery is always above 200 V, often above 500 V. Some OEMs even use around 800 V. These high voltages place very high demands on the electrical insulation. The feedthrough terminals are a particular challenge for the automotive industry and its suppliers. For a long time, high voltage was not rooted in the DNA of this industry. “SCHOTT can, however, point to more than 80 years of experience in sealing metal to glass,” says R&D manager Akira Fujioka. “We have been producing such components for stationary air conditioners and refrigerators for over 60 years,” he adds.

The conditions in road vehicles are extreme. Meeting the industry’s usual requirements in terms of environmental factors, vibrations and severe temperature fluctuations is a tough challenge. In addition, there are the conditions in the compressor itself. The terminal must withstand the various refrigerants such as R134a, R1234yf and R744 (CO₂). At an operating pressure of up to 200 bar (20 megapascals), carbon dioxide makes the greatest demand. The insulation also has to withstand the high voltage. Creepage distances are particularly critical. SCHOTT uses several high-quality materials to optimize the design, including glass. This acts as an electrical insulator and separates the metal contact pins from the support plate. Glass is a core competence of SCHOTT. For 140 years, the company has been known for special high-quality glass types. The company also has a high level of expertise in connecting glass to metal.

Synthetic elastomer for extra protection

There is another material that makes electric compressor terminals from SCHOTT unique, namely an elastomer. While glass is responsible for the actual mechanical connection, the parts made of synthetic rubber prevent condensation which would otherwise shorten the creepage path and encourage sparkover. The elastomer can of course withstand the different lubricating oils for compressors such as PAG and POE. SCHOTT uses different sealing materials on the inside and outside. “After conducting an extensive series of tests our engineers have found the ideal combination,” says Akira Fujioka. The elastic components make the connections more reliable and durable. The highest quality standards also apply to the carrier plates. They must be very flat and smooth so that they too sit tight against the compressor housing.

Electric and hybrid electric vehicles are equipped with battery-powered compressors.

The challenge of high currents

Compressors for 48 V impose different requirements from those of models designed for higher voltages. For new vehicle developments and alternative electrical concepts in particular, power supply from a 48 V system already plays an important role in vehicle electrification. Cars are now being developed that can cover distances up to 30 kilometers with this low voltage. However, the electrical connection for the compressor and therefore the feedthroughs are critical here too, but this time for different reasons than for a high-voltage connection. The demands on the insulation and on the creepage distances are not as serious as those for the transmission of high currents. Aircon compressors require more than two kilowatts of power. At 48 V, that corresponds to between 100 and 150 amps. This requires a correspondingly large cross-section for the power supply terminals.

Copper is the better conductor

SCHOTT has a unique product in its portfolio for this requirement. The conductors are made entirely of copper, which has excellent conductivity. Standard feedthroughs for compressors use stainless steel conductors. The reason is that the coefficient of expansion of this material and its hardness are comparable to those of glass. However, it has a lower electrical conductivity than copper, but copper expands less favorably. This is where SCHOTT’s patented innovation comes in. It compensates for the differences in the expansion of copper conductors and glass insulators. The better conductivity of copper allows the cross-sections to be smaller and the connections to be more compact.

SCHOTT already supplies its electrical feedthroughs to some of the largest manufacturers of electric compressors. The company’s portfolio includes both standardized and customized components.

Rubber and ceramic design e-Compressor