FLEXINITY® mini

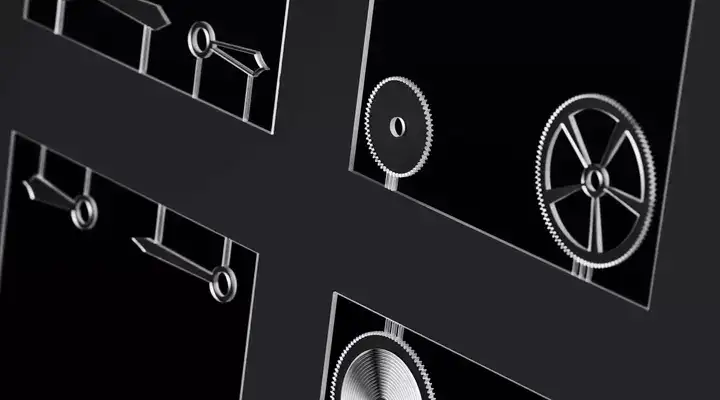

SCHOTT FLEXINITY® mini offers high versatility for small glass parts, delivering highly accurate and strong components down to a few millimeters, equipped with high quality edges and the option to be through structured. The glass parts can be delivered in-frame, making them easy to handle during system integration.A precise solution for thin glass components

SCHOTT FLEXINITY® mini is a brand new product that addresses the fundamental challenges of processing small and thin glass components for electronics and opto-electronics. It delivers all the outstanding features of SCHOTT FLEXINITY® in a tiny form, such as geometrical flexibility and outstanding precision, along with homogenous edge cosmetics and superior strength.

FLEXINITY® mini also offers the opportunity for µ-scale through structures and part-in-frame delivery that’s ready for preparation before system integration (washing, coating). Once your frames have been processed, the glass components are easy to detach, either automatically or by hand. With a freeform tolerance of +/-10µm at dimensions of a few millimeters, perfectly homogenous edge cosmetics, and the option to be structured in small parts, FLEXINITY® mini combines geometrical flexibility with the highest precision.

Small, precise, and easy to handle – but conventional singulation technologies are not the choice

Many industries, such as opto-electronics and semiconductor packaging, rely on small glass components with precise dimensions and high quality edge geometry. These components can be manufactured by a wide range of mechanical singulation (or separation) methods, which require wafer-dicing capabilities using straight and full-body high-speed wheel cutting.

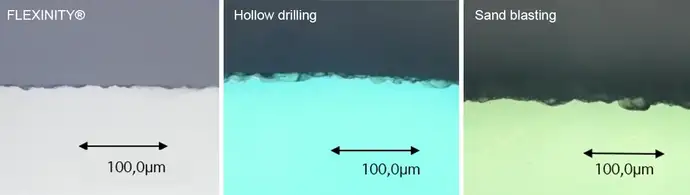

Traditional methods for small-size cutting of flat glass below 10 mm such as CNC cutting, sand blasting or hollow drilling have limitations concerning the final geometry of the glass parts, and run a high risk of uncontrolled randomly distributed edge imperfections.The ideal glass component not only needs to provide homogeneous edge geometry and consistent cosmetic precision, but be delivered in an easy-to-handle and robust format that enables effective preparation for final-system integration.

Key benefits

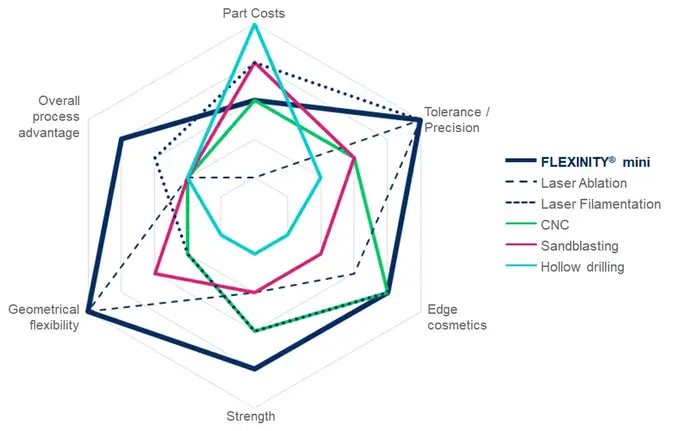

FLEXINITY® mini offers a number of key benefits when compared to products manufactured by alternative singularization processes. These benefits provide FLEXINITY® mini with a series of unique properties and features, which include:

- Small parts

- Accuracy and precision

- High quality edge cosmetics and geometry

- Freeform (almost unlimited)

- A mechanically stable frame that enables effective post processing (washing/coating)

- Part detachment on demand

Key advantages of SCHOTT FLEXINITY® mini

FLEXINITY® mini enables different applications

Application areas can be wide-spread, ranging from housing and packaging of opto-electronic devices using geometrically simple glass parts (see video) up to complex design elements for luxury goods. In the video you see that even small pseudo- 3D haptic elements can be realized.