Product Variants of Battery Lids and Connectors

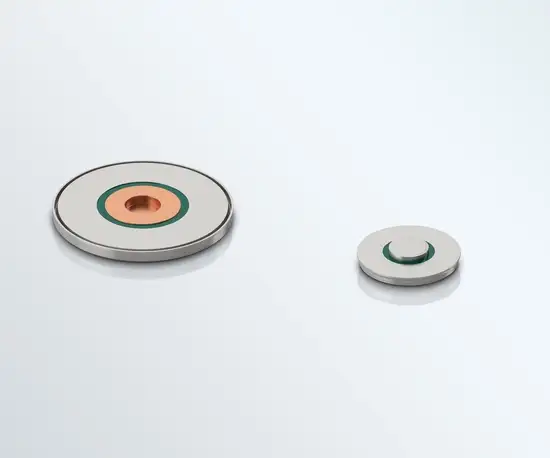

Lithium Primary Battery Covers

- Availability of standard sizes from AA, to C and D Cells.

- Customized designs (cylindrical and prismatic).

- High temperature resistance, ranging from -65°C to more than +150°C.

- Proprietary electrolyte-resistant glass specially developed for lithium primary chemistries, including lithium thionyl chloride (Li-SOCL2), Lithium Manganese Dioxide (LiMO2), Lithium Sulfur Dioxide (LiSO2), and more.

- Hermetic sealing reliably prevents humidity intrusion into the cell housing and electrolyte leakage.

SCHOTT battery covers are trusted by the battery industry worldwide with a proven lifetime of up to 25 years or more.

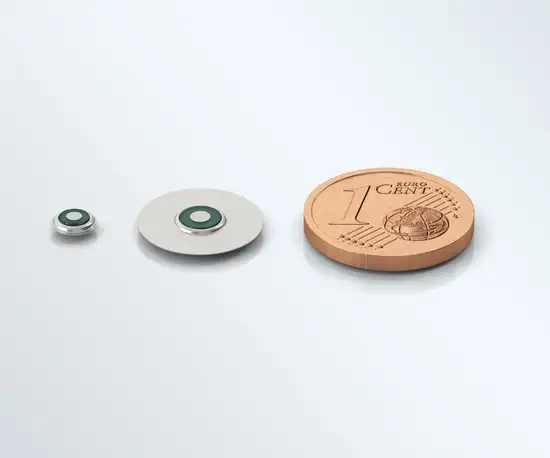

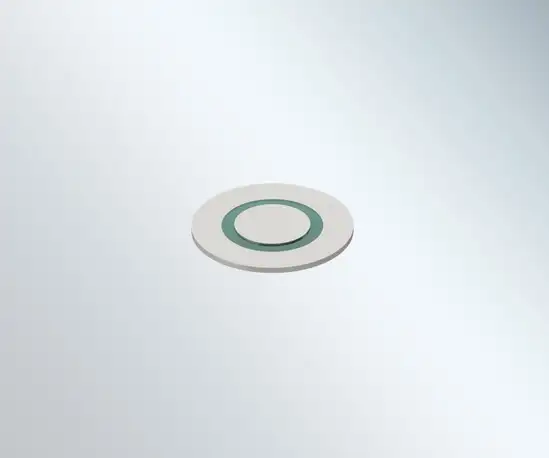

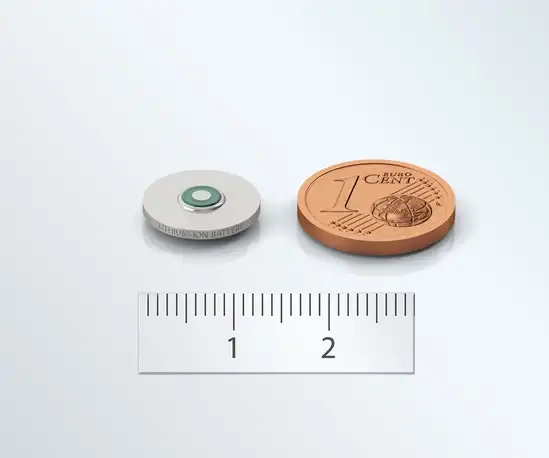

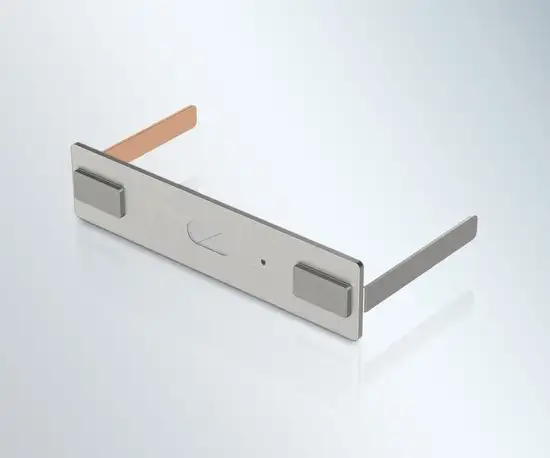

SCHOTT MiniCaps®

- Extremely flat lid design – thinner & mechanically more robust than today’s standard

- Creates space for more electrolyte

- Lid and pins made of stainless steel

- High temperature resistance, from -40° C to over 125° C

- Electrolyte-resistant glass-to-metal sealing

- Customized lid diameters

- For coin cells and pin-type microbatteries

YOUR ADVANTAGES

With their extremely flat design, SCHOTT MiniCaps® create extra space for more electrolyte in the cells compared to conventional polymer-sealed lids. This allows battery cell manufacturers to design tiny and robust cells with extended battery runtimes.

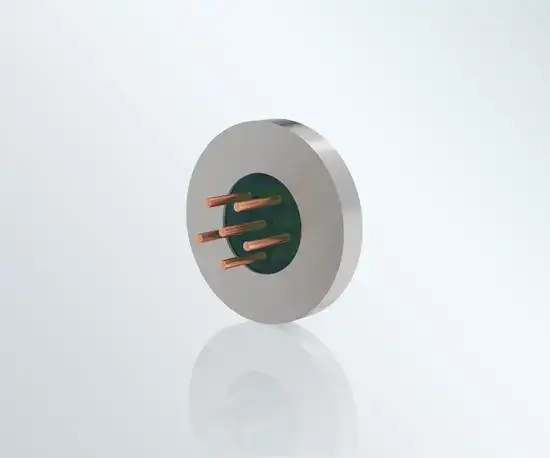

Lithium-Ion Battery Lids

- Simplified, rugged lid design.

- High-temperature resistance, ranging from -60°C to more than +150°C, depending on design.

- Proprietary, electrolyte-resistant glass-sealing, especially developed for a wide range of lithium ion battery chemistries.

- Non-aging, fully hermetic design prevents humidity intrusion into the cell housing.

- Lifetime of up to 25 years.

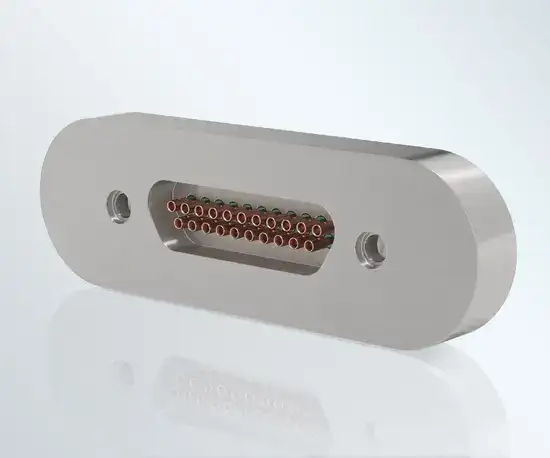

Battery Connectors

-

Made of metal and glass - non-aging, inorganic materials with proven resistance to standard cooling liquids and electrolytes (e.g. NMC, LFP)

-

Leak-tight over the lifetime of the battery module without corrosion, even for small pin pitches

-

Rugged design with high pressure resistance, based on compression sealing technology

-

High temperature resistance from -40°C to over +150°C

YOUR ADVANTAGES

Thanks to proprietary glass-to-aluminum (SCHOTT GTAS®) sealing technology and proven glass-to-metal seals (GTMS), SCHOTT® battery connectors not only provide a leak-tight connection, but also increase safety and reduce the risks of a thermal runaway. Moreover, these battery connectors are suitable for ultrafast charging.

Ultracapacitor Lids

- High-temperature resistance, ranging from -40°C to more than +125°C.

- Electrolyte-resistant, non-aging glass seals that eliminate electrolyte dry-out.

- Up to 20% reduction in electrolyte volume.

- Reduction of capacity losses over time by up to 60%.

- Improvement of internal resistance by over 50%.

Ultracapacitors are now applied for larger-scale usage such as electric vehicles that rely on these components as they have far greater charge storage areas than standard capacitors.

High-power and renewable-energy applications also utilize ultracapacitors. These applications have pushed the demand for powerful, lightweight components that require little or no maintenance, are able to operate in harsh environments across a wide range of operating temperatures, and have high-power density and high reliability. SCHOTTs hermetic covers enable new ultracapacitor designs that push the boundaries of innovation even further.

Carrissa T Ng

Sales Manager, Battery Solutions