Technical Details of ARTISTA® and RIVULETTA®

Two structured glasses, one high standard

ARTISTA®

SCHOTT ARTISTA® extra-clear decorative glass can be processed in the same way as conventional glass – either as safety, laminated or insulation glass. This opens up a variety of additional functions, ranging from thermal to sound insulation.

ARTISTA® offers a number of application possibilities for both interior and exterior use:

- As a full pane

- In stained glass

- As a fused glass

| Nominal thickness | Tolerance | Dimensions* |

|---|---|---|

| 2.75 mm | ± 0.25 mm | 1,000 x 1,500 mm |

| 1,600 x 1,500 mm | ||

| 2,100 x 1,500 mm | ||

| 4.0 mm | ± 0.25 mm | 1,800 x 1,500 mm |

| 2,100 x 1,500 mm | ||

| 2,400 x 1,500 mm | ||

|

2,700 x 1,500 mm |

||

| 6.0 mm | ± 0.50 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm |

||

| 2,700 x 1,500 mm | ||

| 8.0 mm | ± 0.50 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm | ||

| 2,700 x 1,500 mm | ||

| 10.0 mm | ± 0.50 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm |

* Other dimensions upon request

RIVULETTA®

Colorless and clear, RIVULETTA® has an elegant, timeless design. The structured glass is produced by the Fourcault process, first used by the glass industry in 1914. This was the first fully mechanized process for the continual manufacture of sheet glass and involves drawing molten glass through the Fourcault nozzle. This produces the distinctive appearance of machine-drawn glass with a certain thickness tolerance and wavy surface.

| Thickness | Tolerance | Dimensions* |

|---|---|---|

| 4.0 mm | ± 0.25 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm | ||

| 2,700 x 1,500 mm | ||

| 6.0 mm | ± 0.50 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm | ||

| 2,700 x 1,500 mm | ||

| 8.0 mm | ± 0.50 mm | 2,100 x 1,500 mm |

| 2,400 x 1,500 mm | ||

| 2,700 x 1,500 mm |

* Other dimensions upon request

ETA

Glass produced by SCHOTT’s special Fourcault drawn-glass process isn’t covered by the usual glass standards. Therefore, products using this process are also not subject to automatic regulation. ETA (European Technical Assessment) now confirms that SCHOTT Fourcault glass meets the requirements of the standards EN 12150-2, EN 14179-2, EN 14449 and EN 1279-5.

ETA represents an independent, Europe-wide valid certificate of performance for SCHOTT Fourcault glass as both a base glass and a processed product (toughened safety glass, laminated safety glass, laminated glass and insulating glass units). Extensive material testing at an accredited testing institute confirm the certified product properties.

ETA or abZ?

As part of European harmonization, the customary abZ (Germany’s national technical approval) is used only nationally when no European harmonized specifications are available. The ETA (European Technical Assessment) replaces the abZ for member states of the European Union.

The point of contact for both certifications is the Deutsches Institut für Bautechnik (DIBt – German Institute for Construction Technology).

Customer benefits

Customers can be assured that SCHOTT Fourcault glass can be processed into standard construction products, such as toughened safety glass, laminated safety glass, laminated glass and insulating glass units, in accordance with standards and can be designated as such.

That means no more time-consuming documentation and approval procedures, and processing options can be clearly communicated to customers using familiar terminology.

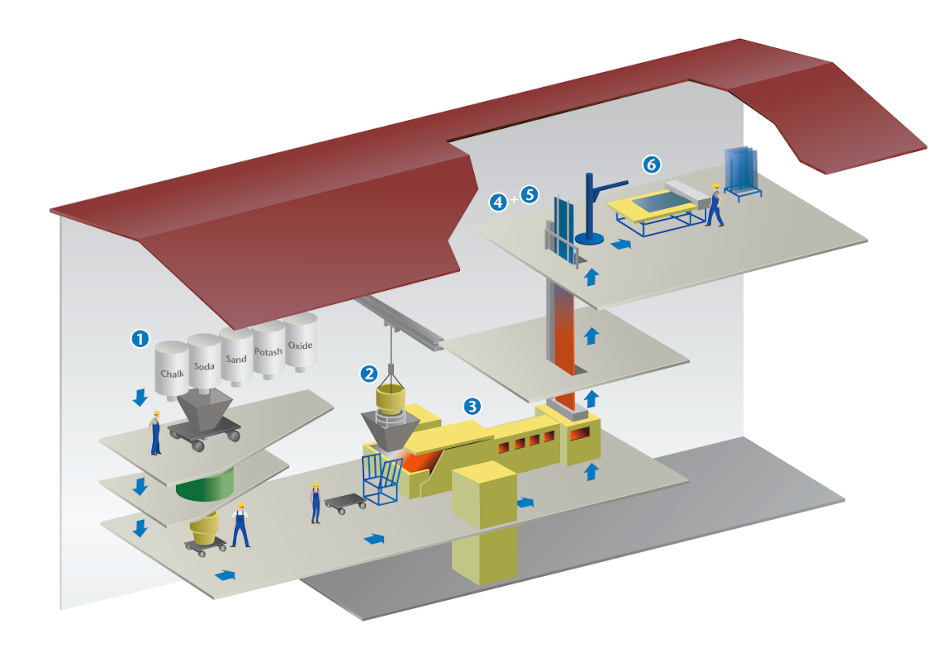

Production process

ARTISTA® and RIVULETTA® are produced by the Fourcault process, the first fully mechanised process for the continual manufacture of sheet glass. In this process, molten glass is drawn through a Fourcault nozzle that produces the distinctive appearance of machine-drawn glass, with a certain thickness tolerance and wavy surface.

The Fourcault process involves six different stages:

- Preparation of batch

- Fill in of batch

- Glass melting

- Up-draw process

- Cooling down

- Edge cutting