Circling back to the future

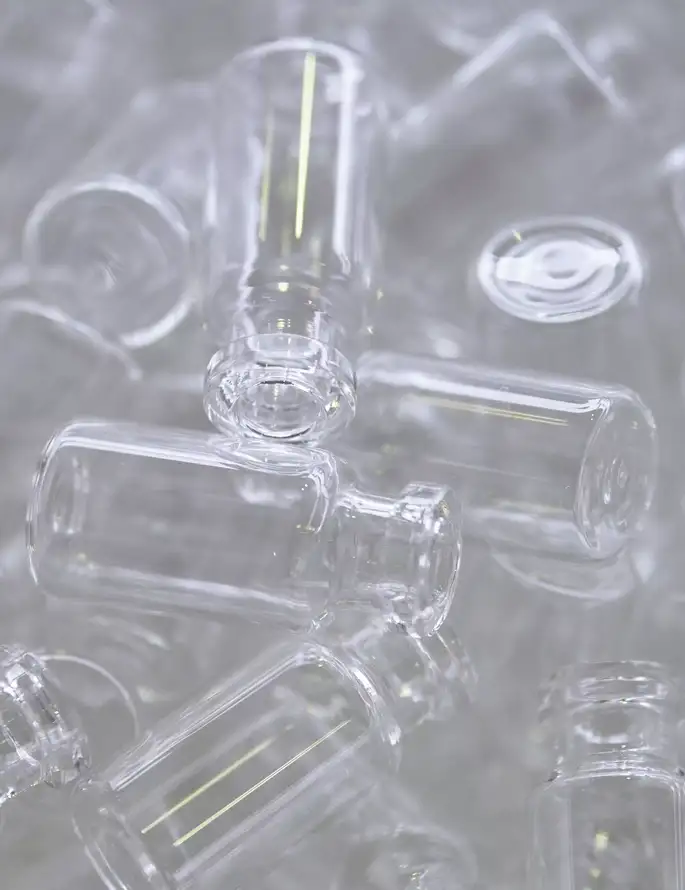

With its ambitious sustainability goals, SCHOTT is making a circular economy an important priority. Its Tubing division and a healthcare company have teamed up to return unused glass vials into production for the first time.

With a focus on sustainability, SCHOTT and Sanofi have partnered to showcase the potential of a circular economy in specialty glass production.

- Challenges were faced in reversing the supply chain and ensuring glass purity during the pilot project.

- The successful material loop closure with a pharma customer advances SCHOTT's sustainability goals.

- The collaboration reveals the potential of circular economy solutions in the pharmaceutical industry and beyond.

At first glance, it might sound simple: A healthcare company has unused medicine vials left over. Instead of throwing them out, it sends the glass containers back to the glass manufacturer, who melts them down and uses them as raw material. This is precisely what is happening between healthcare company Sanofi and specialty glass manufacturer SCHOTT. "Implementing this collaboration was anything but easy or trivial," says Marius Amschler. He is SCHOTT’s product manager for pharmaceutical glass tubing and a sustainability expert, and he led the pilot project which saw SCHOTT successfully close its material loop with a pharma customer for the first time. "We had to turn the entire supply chain upside down and turn our usual processes on their head." Suddenly, the customer was the supplier, and the producer was the customer. There wasn’t even a suitable solution in the ordering software, for example, to name just one of many smaller and larger challenges that the team had to face.

From the end of the supply chain back to the beginning

On-site visit to the healthcare company Sanofi: It is still early this cold February morning. A light mist shrouds the landscape. The day only seems to be slowly awakening. But the Industriepark Höchst near Frankfurt has been a hive of activity for hours. Around 22,000 people work here on 1,140 acres, the same size as a small town.

About Sanofi

Sanofi is one of the world’s largest healthcare companies, with its headquarters in Paris and 59 production sites worldwide. The company employs over 90,000 people and has an annual turnover of around 43 billion euros. Its German subsidiary Sanofi-Aventis Deutschland GmbH employs 7,750 people and is headquartered in the Industriepark Höchst. Sanofi researches the causes of diseases, looks for starting points for drug treatment, develops drugs, produces active ingredients, and supplies these and finished drugs worldwide. Like SCHOTT, Sanofi has set ambitious sustainability targets: among other things, the Group aims to become carbon neutral by 2030 and climate neutral by 2045. To minimize its environmental footprint, Sanofi is constantly looking for circular economy solutions: for example, 50% of polystyrene trays used in pen production are already being recycled.

In his neon yellow winter jacket with the SCHOTT logo on his chest, Marius marches across the grounds of one of the largest industrial parks in Germany. Arriving at Sanofi's main building, he meets Marco Müller, Sanofi’s Environmental Manager who initiated the project. The two have gotten to know each other well. They have spent many hours communicating over the past 12 months - by email, phone, and in person on-site. "We have been looking for solutions for a long time to avoid having to dispose of the high-quality pharmaceutical glass used to make the vials or syringes that we fill with medicines so that we do not have to dispose of them, but can return them to the cycle - for example, in the case of production rejects," says Marco about Sanofi's sustainability efforts. However, this is not easy, especially with glass which has already been in contact with medical products. "For some time now, we have been thinking about what a possible project could look like. When it became clear that there were still a few pallets of unfilled vaccine vials in our high-bay warehouse that we could no longer use, it was just what we needed for a first experiment that we had been preparing with SCHOTT for some time," explains Marco. After a few discussions with Amschler from SCHOTT, the pilot project was born.

The purity of the glass is essential

"We immediately recognized the request from Sanofi as a huge opportunity. After all, SCHOTT has set itself very ambitious sustainability goals among specialty glass manufacturers worldwide. Circular economy and recycling are enormously important building blocks for achieving these goals," Marius explains. It goes without saying that internal production waste from tubing production has always been returned to the glass melt. "And now we have the opportunity to work with a healthcare company and explore new paths," explains the Product Manager, who is based at SCHOTT’s main tubing production in Mitterteich, Bavaria.

Quality is also crucial for these new methods: the purity of the glass is extremely important in this process. "We can't just feed any glass into our melting process," explains Marius. He must be able to clearly verify that it is only FIOLAX® clear glass. That's because not all glass is the same. Just like when you bake a cake, every company has its own recipe. And in the pharmaceutical industry in particular, we have to guarantee absolute quality and purity." However, the vial packaging also presented challenges, both logistically and financially.

Short distances: a recipe for success

Change of location: Marius and Marco have taken a short walk from Sanofi to Infraserv Höchst's waste disposal facility. "Finding a partner so close by to unpack the pallets for us was a key factor in the project’s success," reports Marius. The key person here was Anke Reining, Head of Recycling and Waste Management at Infraserv Höchst. "We work with Sanofi in many areas, including glass recycling," she says over the clinking of the bottles. Meeting SCHOTT's quality standards is not a problem for her. After countless emptied trays, the wire box is finally filled up and emptied into an orange 40-m³ container with the help of a forklift truck. Once the container is full, a truck with the vials sets off on the 30-minute journey to SCHOTT's headquarters in Mainz, where the company produces glass tubing, among other products.

Why circular economy?

Since the Industrial Revolution, the linear economy, also known as the disposable economy, has prevailed worldwide. Resources and raw materials are extracted, processed, and used for a specific purpose. At the end of their service life, the products are disposed of in landfills or recycled thermally. According to a study by management consultancy Roland Berger, 91% of our economy still has a linear structure. The circular economy is the opposite of this. It aims to minimize the use of resources, waste production, emissions, and energy waste by slowing down, reducing, and closing energy and material cycles. This concept was first implemented in 1990 with the green dot for packaging and became popular in society.

Reusing and recycling products brings many advantages.

- Slowing down the use of natural resources

- Reducing landscape and habitat destruction and the loss of biodiversity

- Reducing greenhouse gas emissions and energy consumption

- Strengthening competitiveness: efficient reuse of products and promotion of recycling processes create new fields of innovation

- Increasing resilience to supply chain problems and high energy prices

- Cost savings, because the production of primary materials from recycled raw materials can be cheaper than from primary production

"This second local proximity is another success factor. It was the only way we could make the project economically viable," explains Marius. "Because, to put it bluntly, cullets don't bring big money or savings," he says with a wink. The team had to monitor the handling and transportation costs closely. Today, disposal is often cheaper than recycling and is therefore still the first choice for many companies. "This shows which company takes sustainability seriously," says Marius. “You sometimes have to pay for it, especially at the beginning of a pilot phase. Not necessarily just financially but also in terms of people. Many colleagues were involved in this project. Their commitment was truly amazing. And not just internally at SCHOTT, but also at Sanofi and Infraserv," he adds. He is thrilled to be doing pioneering circular economy work with a healthcare company. "And in our case, we even found so many good solutions in the end that none of the parties involved were at a financial disadvantage," he says. "If you find the right levers, circular economy can be ecologically and economically sustainable. This poilot project emphasizes, it can work."

A step in the right direction

Another change of location: Dr. Tobias Rothenfluh is standing in SCHOTT's cullet warehouse, waiting for the truck from Höchst. Behind him, a meter-high mountain of vials from Fiolax® clear glass tubing is already piling up. Tobias is responsible for batch supply at the Mainz site. He collects raw materials for glass melting - which always includes a certain amount of cullet. "This has two advantages," explains Tobias. "Firstly, the cullet is reused to save raw materials. Secondly, they are easier to melt, meaning we need a little less energy in glass production." With temperatures of up to 1,700 degrees, which need to be maintained in the melting tanks around the clock, this is not an insignificant factor.

A van with a twelve-meter-long container turns the corner. Maneuvering backward between the walls of the cullet warehouse, the driver tips his load and lets the bottles trickle out of the container - a noisy procedure. To the left and right of the Fiolax® clear cullet store, other types of cullet in different colors are piled up in additional troughs: up to 20 different types at peak times. They are always stored by type and only returned to the appropriate furnace for the respective glass product. "The cullet here comes from our direct production rejects, e.g., if the geometry of the glass does not fit or the inspection machines reject the tube due to dimensional or visual defects," explains Rothenfluh. "The fact that we have now recovered cullet or vials from the market is unique. And it’s a step in the right direction," he says.

Marco Müller and Marius Amschler are also convinced of this. " We agree that the collaboration must continue, even though the pilot project has ended," says the SCHOTT Product Manager. "Using a relatively simple example, we have worked through how we can turn the supply chain around, which processes we need to establish at Sanofi for this, and which quality and cost aspects we need to pay attention to," says Sanofi Environmental Manager Marco. The same thing has happened on the SCHOTT side, emphasizes Marius. "Now we can take the next step and focus on glass rejects that have already been in contact with medicines," he says. Like many healthcare companies, Sanofi is already working intensively on this issue. Because one thing is certain: this is by no means the end of the story.

On the way to a more sustainable future, the experts will move closer piece by piece - or sliver by sliver. SCHOTT and Sanofi are currently planning further joint projects for the healthcare industry, which will soon be implemented. At the same time, the Mainz-based materials expert is preparing to launch pilot projects involving glass-ceramics and other types of glass.