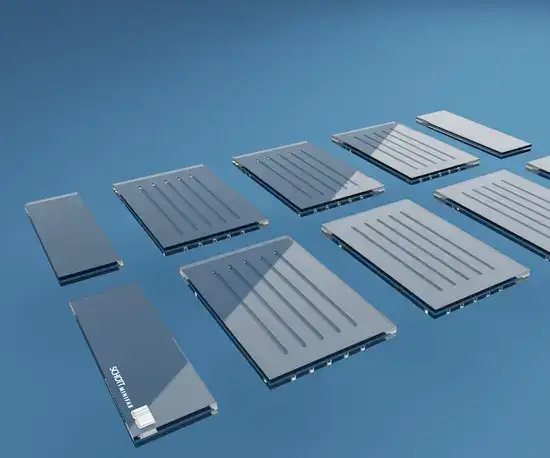

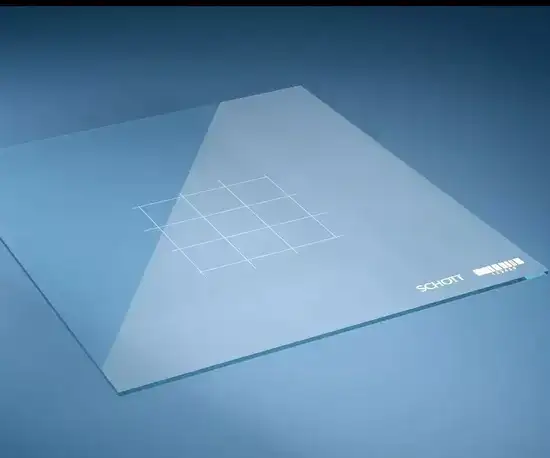

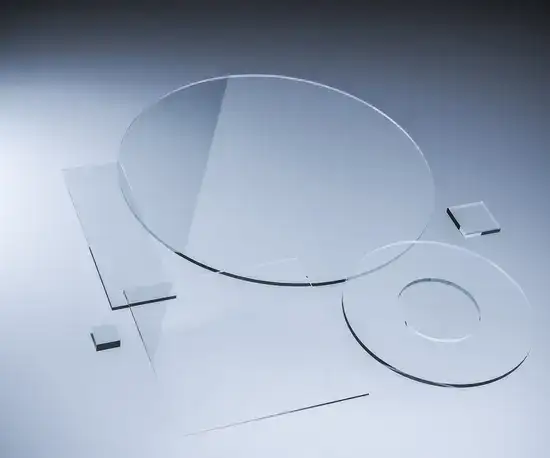

NEXTERION® glass substrates

To cater to the demand for customized products, we specialize in the development of distinctive formats, materials, coatings, structuring and bonding solutions. Leveraging our stringent quality standards and efficient volume production methods, we empower our customers to achieve consistently reproducible results, addressing the evolving challenges of diagnostic and life science endeavors.

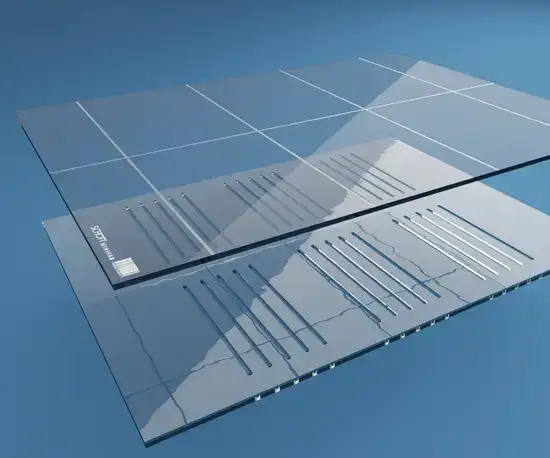

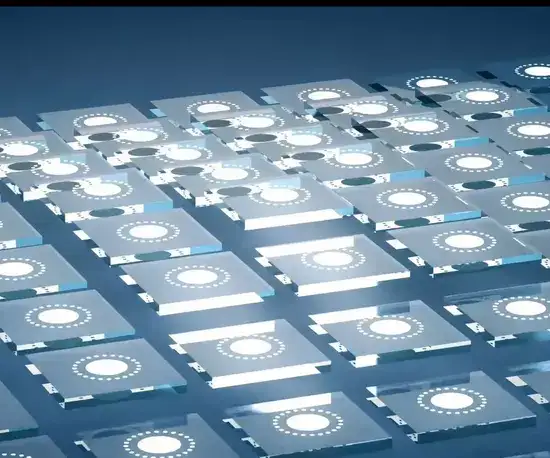

NEXTERION® bonded glass substrates

CHARACTERISTICS

-

Tape Bonding

For all NEXTERION® taped-bonded products the channels are formed via adhesive tape. The channel depth is defined by tape thickness. The bonding process takes place at room temperature. This allows an optional functional coating on either top or bottom plate. -

Fusion bonding

All NEXTERION® fusion-bonded products are fully glass-based systems either in two or in three layer-designs. The layers are aligned and directly bonded via pressure contacting. The fusion bonding occurs at high temperatures (~ 500 - 600 °C). SCHOTT MINIFAB offers fully glass-based systems either in two or three layer-design. The layers are aligned either via wet (water) or via direct pressure contacting.

YOUR ADVANTAGES

Manufacturing takes place in ISO class 5 environment, all relevant processes are in place for diagnostic company needs. In the following an overview of the available bonding methods including design options.

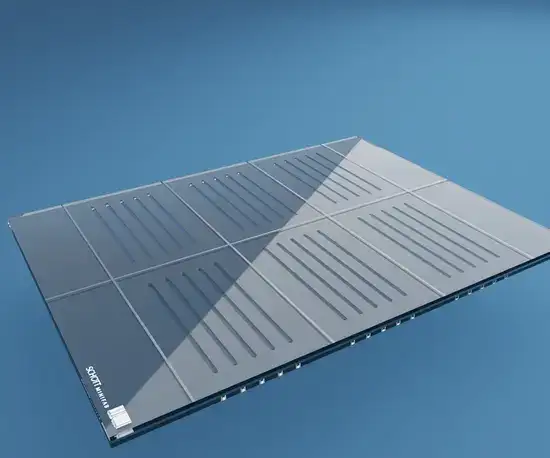

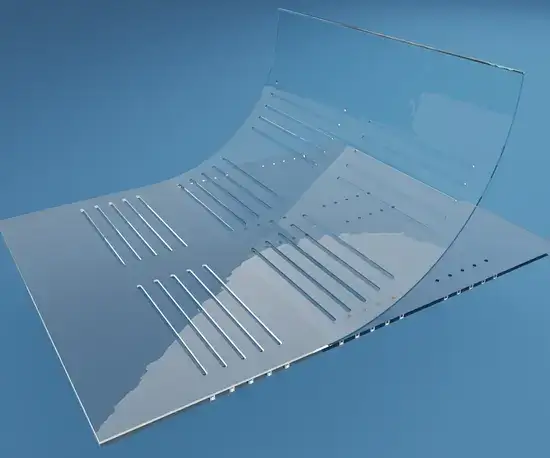

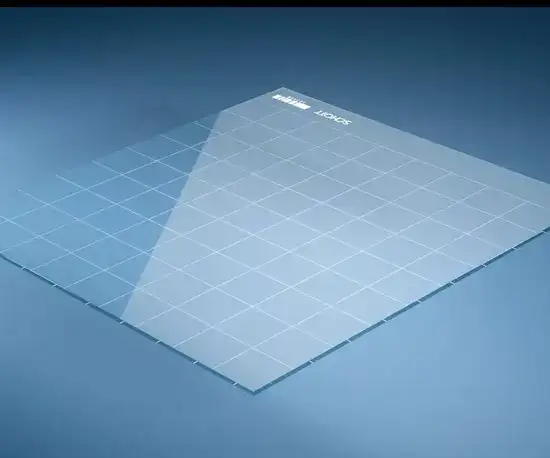

NEXTERION® structured glass substrates

CHARACTERISTICS

Laser ablated structures are deepenings in the surface of the glass with a depth of 10 µm up to 100 µm. Depending on the thickness (typical between 0.17 and 2.75 mm) of the material and the shipping format, the minimum chip size does vary.

YOUR ADVANTAGES

As longstanding manufacturer of technical glass, SCHOTT MINIFAB is able to maintain thorough control over all processing steps- starting with the initial glass production and ending up with the product delivery. All NEXTERION® products are manufactured according to the most stringent industry standards, guaranteeing that customers receive the highest quality and most reproducible products.

-

very homogenously coated

-

available with markings or barcodes at no extra processing time

-

available in a high batch quantity

-

very smooth edges for assembly

-

inexpensive

We can further customize NEXTERION® PreScora substrates with markings including logos, barcodes, fiducial marks and graphics that are robust enough to withstand challenging biomedical laboratory procedures. These markings can be added at any location on or within the glass surface.

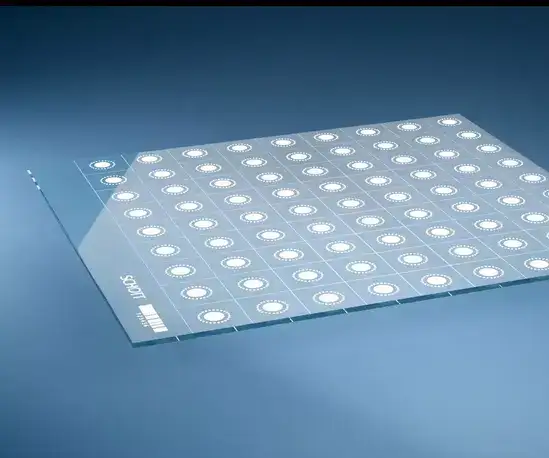

NEXTERION® coated glass substrates

CHARACTERISTICS

Our standard family of coatings include:

-

Aldehydesilane Coating

-

Aminosilane Coating

-

Epoxysilane Coating

-

3-D Hydrogel Coating

-

3-D Polymer Coating

-

Streptavidin Coating

-

Poly-L-Lysine Coating (PLL)

-

Customized Coating

With a wide range of available coating technologies, e.g. dip coating, chemical vapor deposition (CVD), sputter deposition, solvent-based reactor method, spin coating we are able to scale manufacturing. Also the development of customized coatings or apply coatings developed by our customers belong to our portfolio.

YOUR ADVANTAGES

-

High-quality borosilicate glass

-

Various dimensions and thicknesses

-

ISO class 5 clean room production

-

ISO 19001 and 13485 certified

NEXTERION® uncoated glass substrates

YOUR ADVANTAGES

BOROFLOAT® 33 and D 263® are produced with the purest raw materials and manufactured with stringent quality controls systems. The manufacturing process results in a pristine, fire-polished surface, making it the perfect material for diagnostics and life science research. The uncoated glass material types are cleaned in an ISO class 5 cleanroom and offered in standard and custom formats, to meet tolerances and technical specifications.

Want to know more? Let's talk

Whether you need more information, samples, a quote, or advice for a project, I would be delighted to talk to you.