Technical Details of CERAN®

Cooking with CERAN® confidence

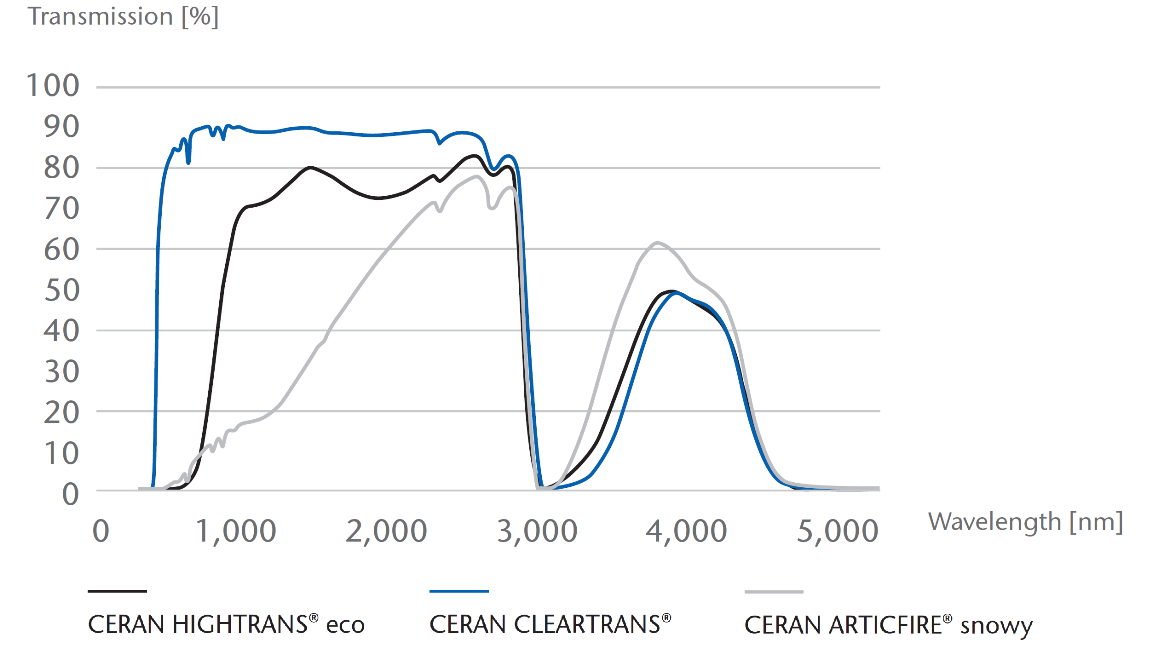

Optical characteristics

Typical transmission graph of different ceramization states with sample thickness of approximately 4 mm. This graph is based on data from individual measurements. Deviations may result from the manufacturing process.

All technical data presented must be understood as typical averages values. Detailed information on the different material types is documented in separate data sheets or will be provided on the customer’s special request. Values, for which no generally accepted measuring method exist, such as by technical standard, are specified and explained.

Mechanical characteristics*

Density: ρ ≈ 2.6 g/cm³

Modulus of elasticy (ASTM C-1259): E ≈ 95 x 10³ MPa

Poisson’s ratio (ASTM C-1259): μ ≈ 0.25

Knoop hardness (ISO 9385): HK 0.1/20 ≈ 600

Bending strength: σ̅ bB ≥ 110 MPa

* These values are for CERAN HIGHTRANS® eco at room temperature.

All technical data presented must be understood as typical averages values. Detailed information on the different material types is documented in separate data sheets or will be provided on the customer’s special request. Values, for which no generally accepted measuring method exist, such as by technical standard, are specified and explained.

Thermal characteristics*

Thermal conductivity (DIN 51936, ASTM 1461-01): λ (100°) ≈ 1.6 W / (m×K).

Thermal shock resistance: Requirements according to EN 60335-2-6 and UL 858 are fulfilled.

* These values and standards are for CERAN HIGHTRANS® eco.

All technical data presented must be understood as typical averages values. Detailed information on the different material types is documented in separate data sheets or will be provided on the customer’s special request. Values, for which no generally accepted measuring method exist, such as by technical standard, are specified and explained.