Ultimate plant growth through indoor farming LEDs

Key requirements for LED modules and cover glass in indoor farming

The heart of every indoor farm is its LED lighting system. These fixtures must deliver a precisely defined light spectrum from 350–1.000 nm to optimize photosynthesis, all the metabolic processes and temperatures that drive plant growth. At the same time, not a single photon can be wasted—any absorption or reflection directly impacts growth rate and energy consumption.

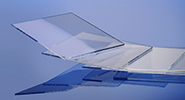

In practice, LED modules face dust, humidity, and frequent wash-down cycles. The LED cover glass is the front pane of your lighting module in vertical and container farms. It shields the LED chips from moisture, cleaning agents, and mechanical wear—without scattering or absorbing light. Only flawless cover glass lets 100 % of your source output through, ensuring perfectly even illumination across every canopy layer.

Maximize plant growth with indoor farming LEDs

Characteristics of the ideal LED Cover

An LED cover glass must meet five core requirements:

- Optical purity

Uniform transmission from 350–1.000 nm to support photosynthesis and secondary plant processes. - Protective function

Resistance to moisture, vapor, and cleaning chemicals without any optical aging. - Mechanical robustness

High scratch, impact, and flexural strength to withstand the rigors of rack- and container-based farms. - Coating compatibility

Long-lasting adhesion of AR, easy-clean, or hydrophobic coatings—even after a thousand cleaning cycles. - Thermal management

Efficient heat conduction and low thermal expansion so seals remain intact and LEDs are protected from hot-spots.

B 270® - the ideal glass solution for indoor farming LED covers

B 270® technical highlights

Transmission curve

At 2 mm thickness, SCHOTT B 270® delivers up to 92 % transmission in the plant-critical 350–1.000 nm spectrum. That makes it the ideal cover glass for LED modules in indoor farms—minimizing photon losses and ensuring that virtually the entire Photosynthetic Photon Flux (PPF) generated by your LEDs reaches the canopy unimpeded, for faster growth and higher yields.Comparision to other glass types

| Factor | Float soda-lime glass | Polycarbonate (PC) | SCHOTT B 270® |

|---|---|---|---|

| nUV transmission (350–450 nm) | Up to 10 % absorption | Up to 15 % absorption | Up to 2 % absorption |

| PAR transmission (400–700 nm) | 88–90 % | 85–88 % | 90–92 % |

| Optical homogeneity | High | Medium | Very high |

| Mechanical robustness | Medium | High | High |

| Thermal stability | High | Low | High |

| AR coating adhesion | Moderate (yellowing over time) | Limited | Excellent |

| Cleaning resistance | Yellowing over time | Good | Excellent |

| Seal stability | Expansion | High expansion | Minimal expansion |

| Available thicknesses | 1–6 mm | 1–8 mm | 0.5–10 mm (extensive) |

| Cost-to-performance ratio | ++ | ++ | ++++ |

Color rendering & colorimetry

Neutral lighting and consistent color fidelity are critical for indoor-farm LED cover glasses—whether for camera-based crop monitoring, phenotyping systems, or simple visual inspections by farm staff. The table below shows how SCHOTT B 270® compares to float glass and polycarbonate:

| Metric | SCHOTT B 270® | Float Glass | Polycarbonate (PC) |

|---|---|---|---|

| ΔE*ab (350–700 nm) | < 1.0 | 1.5 – 2.0 | > 3.0 |

| White-point temperature | 6 500 K | 6 300 K | 6 200 K |

| Color consistency across batches | Very high | Medium | Low |

Coating and surface compatibility (material & process advantages)

| Property | B 270® Advantage |

|---|---|

| Homogeneity | Highly uniform glass composition – ensures reproducible coating tests |

| Surface (Roughness) | Precision-polished to ≤ 1 nm – minimal polishing required before coatings |

| Coating temperature | 542 °C transformation temperature – compatible with demanding AR and hydrophobic processes |

| Cleaning resistance | ≥ 1 000 H₂O₂-cleaning cycles without performance loss |

Thickness portfolio

B 270® is available from 2-10 mm of standard thicknesses for purchase-ready via global distributor network. Other thicknesses on request. Standard sizes up to 1680 x 900 mm.