NEXTERION® coated glass substrates

With NEXTERION®, SCHOTT MINIFAB offers functional coating chemistries for DNA and protein microarrays and a wide range of other applications to meet your exact needs. Find out more about the coating that fits your challenge.

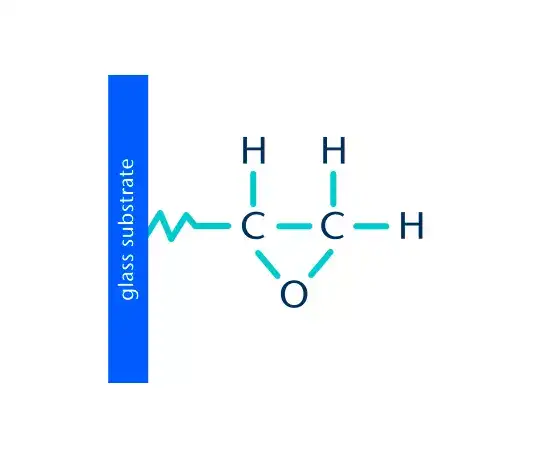

Epoxysilane coating (E)

Product information

These substrates have a multi-purpose epoxysilane layer that will covalently bind most types of bio-molecules including amino- and non-modified DNA, RNA, and proteins.

The defect-free surface features a uniform epoxysilane layer that provides a high covalent coupling efficiency together with a very low background. The robust and stable surface chemistry easily allows long print runs. This type of substrate is easy to use and protocols for many applications are published in literature.

Produced in ISO class 5 clean room conditions using a standardized process and running a stringent quality control system, epoxysilane coated substrates are available in standard and custom formats.

Probe types

- Amino-modified oligonucleotides (necessary for < 20 mers)

- Unmodified oligonucleotides

- PCR products

- ZIP code oligonucleotides

- BACs, PACs, YACs, plasmids

- L-DNA, cDBA, RNA

- Serum samples

- Proteins, Antibodies, Peptides, Glucans

Shelf life

Twelve months for sealed packages at room temperature.

Immobilization method

Covalent binding via amino-, thiol- and hydroxyl-reactive chemistry.

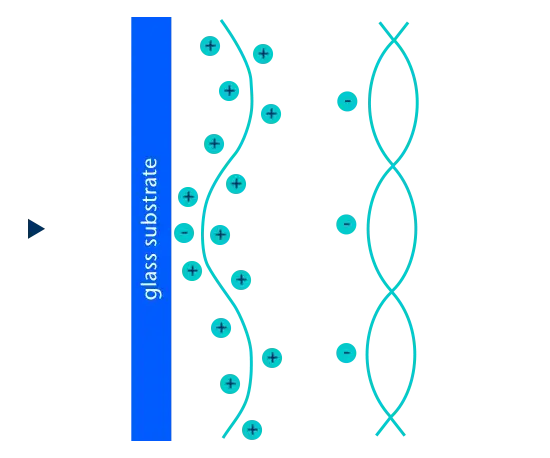

3-D Hydrogel coating (H)

Product information

This type of coating has proven to be a very attractive alternative to the commonly used nitrocellulose-coated slides, especially when low background noise or slide transparency are important. It ensures an extremely low non-specific binding and helps preserving the native three-dimensional structure of complex bio-molecules, thus maintaining conformation and functionality. As a result, it attains excellent signal-to-background ratios.

Produced in ISO class 5 clean room conditions using a proprietary thin-film deposition process and running a stringent quality control system, the 3-D hydrogel coating is offered in standard and custom formats.

Probe types

- Amino-linked glucans

- Antibodies and antibody fragments

- Functional proteins such as enzymes or receptors

- Small protein fragments such as peptides

- Amino-modified oligonucleotides 16 to 70 mers

Shelf life

Twelve months sealed packages when stored at - 20° C.

Immobilization method

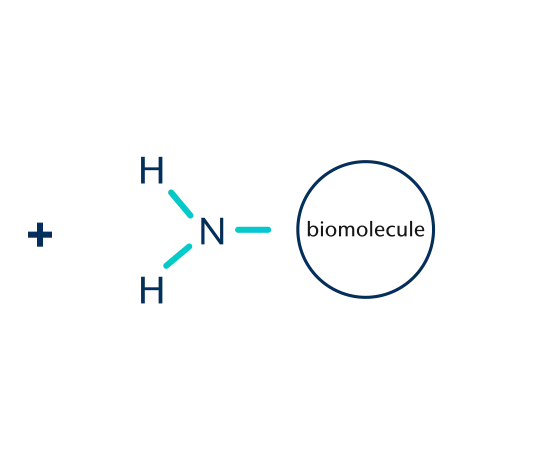

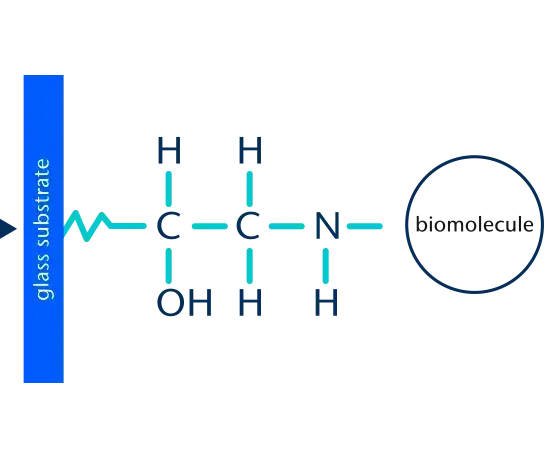

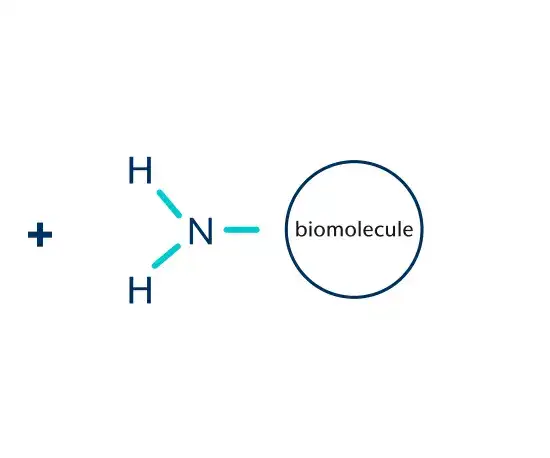

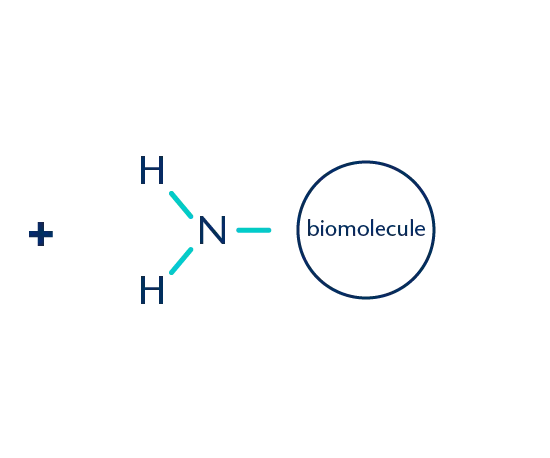

Covalent binding via amine reactive chemistry.Aminosilane coating (A+)

Product information

The coating is based on very short chains of aminosilanes that demonstrate high signal intensities and exceptionally low background noise signals in comparison to other commercially available aminosilane coated substrates. Produced in ISO class 5 clean room conditions using a standardized process and running a stringent quality control system, aminosilane coated substrates are available in standard and custom formats.

Probe types

- BACs, PACs, YACs

- Oligonucleotides ≥ 40 mers

- cDNA

- PCR products

Shelf life

Nine months for sealed packages at room temperature

Immobilization method

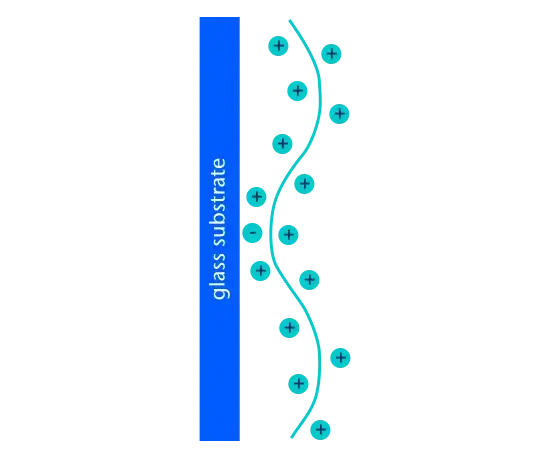

Ionic interaction followed by cross-linking via an additional UV or baking st

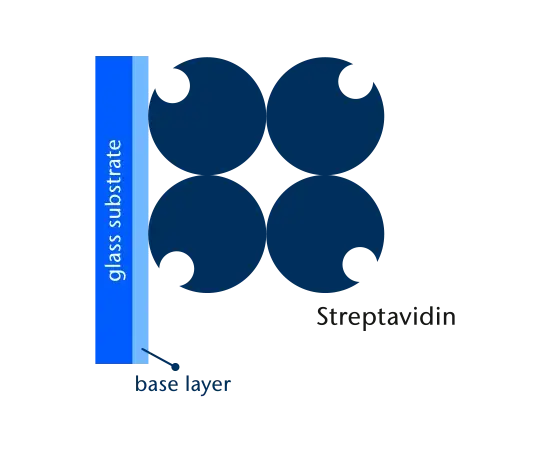

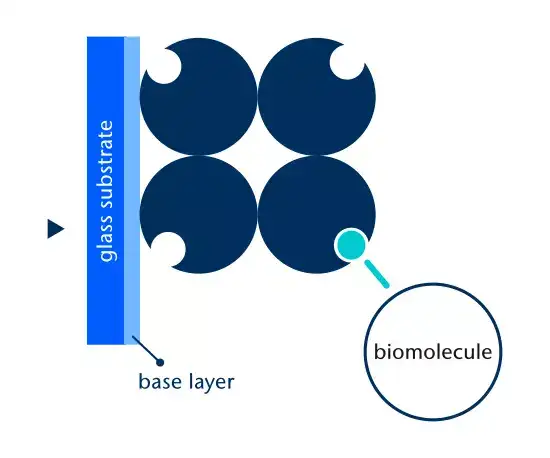

Streptavidin coating (HS)

Product information

The proprietary thin-film deposition coating process produces a very high density, as well as an extremely uniform coating of streptavidin molecules. The resulting surface has a very high binding capacity combined with a low signal variance across a single slide as well as different slides and batches.

Produced in ISO class 5 clean room conditions using a standardized process and running a stringent quality control system, streptavidin coated substrates are available in standard and custom formats

Shelf life

Six months for sealed packages when stored at – 20° C.

To protect the activity of the streptavidin layer, a protective coating is added on top of the reactive coating prior to packaging. This layer must be removed prior to use by a washing step. The streptavidin layer on Slide HS is very sensitive to elevated temperatures. It is therefore necessary to ship the product in a frozen state with dry ice. The product must immediately be put into a freezer upon arrival. Repeated freeze and thaw cycles should be avoided.

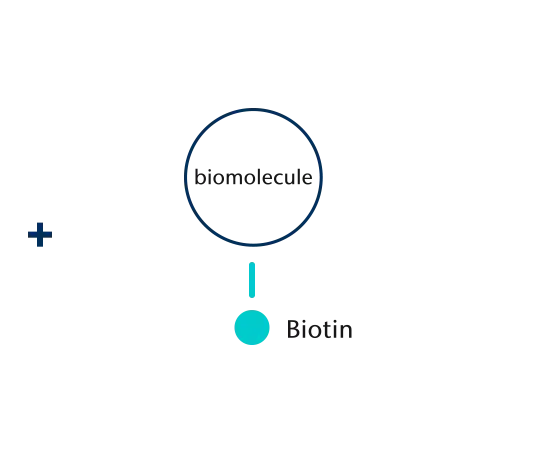

Probe types

-

All molecules that can be biotinylated

Immobilization method

Binding via biotin

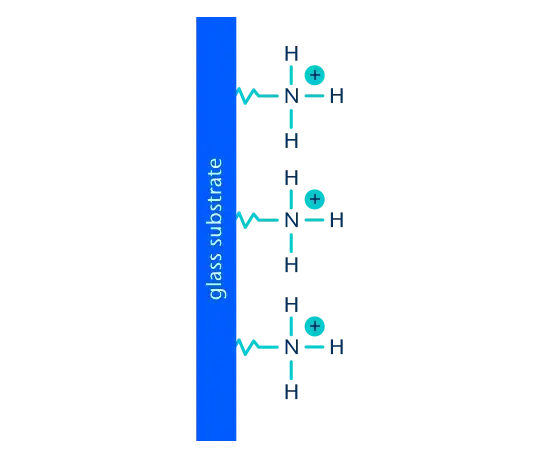

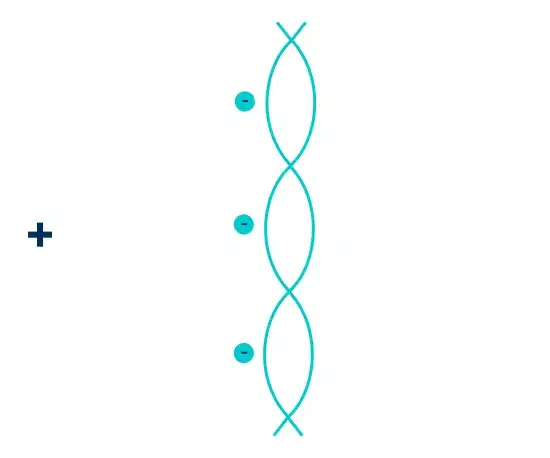

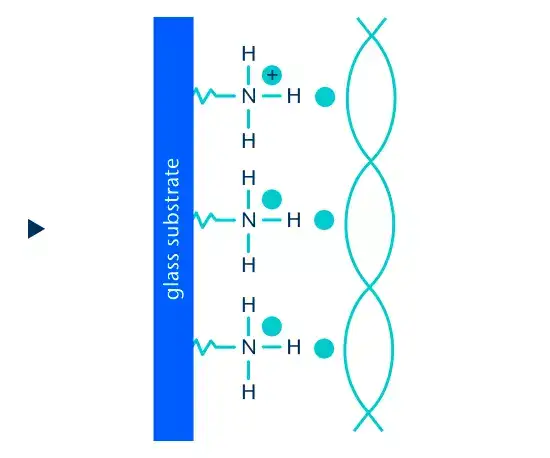

Poly-L-Lysine coating (PLL)

Product information

This coating is based on long chains of positively charged L-lysin polymers. Produced in ISO class 5 clean room conditions using a standardized process following a stringent quality control system, NEXTERION® poly-L-lysine coated substrates are available in both standard and custom formats.Probe types

- BACs, PACs, YACs

- Oligonucleotides ≥ 40 mers

- cDNA

- PCR products

Shelf life

Six months for sealed packages at room temperature.

Immobilization method

Ionic interactions

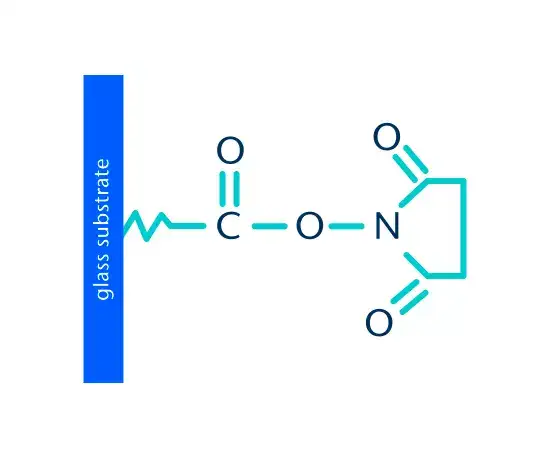

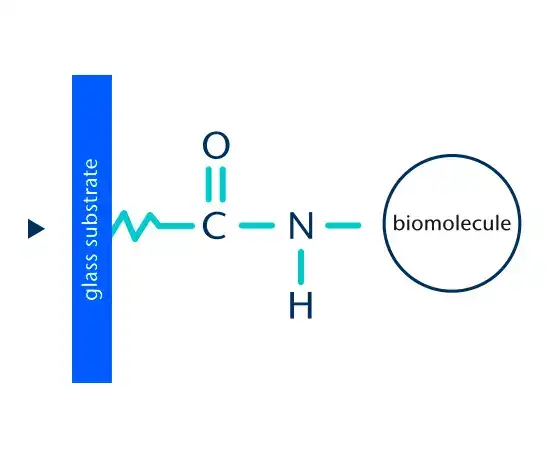

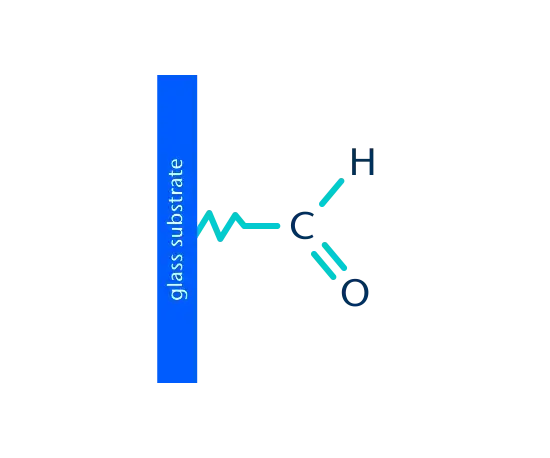

Aldehydesilane coating (AL)

Product information

The covalent bond formed at the terminus of the nucleic acid offers both: stability and maximal base pairing opportunity. The covalent binding diminishes sample loss during the course of experiments and permits stringent washing steps, which reduce background noise and allow greater sensitivity. Additional immobilization steps, such as baking or UV cross-linking, are not required for immobilization.

Produced in ISO class 5 clean room conditions using a standardized process and running a stringent quality control system, aldehydesilane coated substrates are available in standard and custom formats.

Probe types

- Amino-modified PCR products and BACs/YACs

- Amino-modified oligonucleotides

- Small protein fragments such as peptides

Shelf life

Nine months for sealed packages at room temperature

Immobilization method

Covalent binding via amine reactive chemistry.

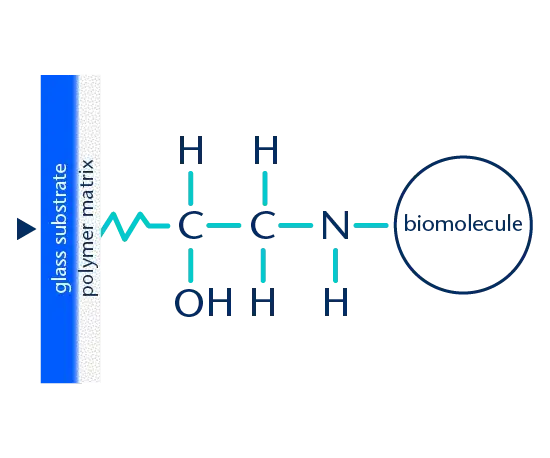

3-D Polymer coating (P)

Product information

SCHOTT specifically developed the 3-D Polymer coating as a dedicated substrate surface for printing low-density antibody microarrays. It produces excellent signal-to-background ratios, and exceptionally wide dynamic ranges compared to conventional “two-dimensional” coatings through a unique combination of low non-specific binding characteristics, and high probe loading capacity.

Produced in ISO class 5 clean room conditions using a pro-prietary thin-film deposition process and running a stringent quality control system, the 3-D Polymer coating is offered in standard and custom formats.

Probe types

-

Amino-linked glucans

-

Antibodies and antibody fragments

-

Functional proteins such as enzymes or receptors

-

Small protein fragments such as peptides

-

Amino-modified oligonucleotides 16 to 70 mers

Shelf life

Twelve months sealed packages when stored at - 20° C.

Immobilization method

Covalent binding via amine reactive chemistry.

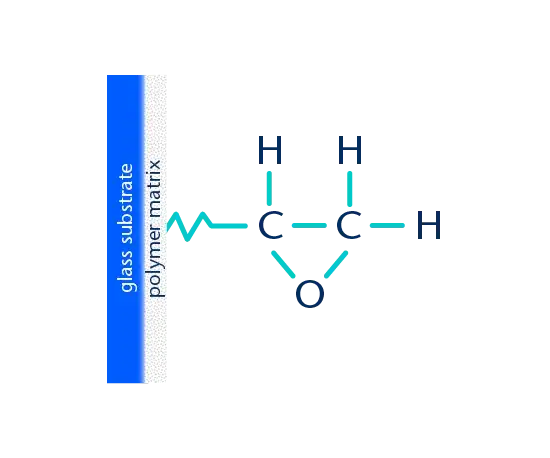

3-D Epoxy coating (E+)

Product information

NEXTERION® specialized polymer coatings have anti-fouling properties that prevent the non-specific adsorption of unwanted biomolecules to glass, metals, and plastics, polycarbonate (PC) and polymethyl methacrylate (PMMA) and improve selectivity compared to silan-based coating systems.

Probe types

- Unmodified oligonucleotides

- PCR products

- Antibodies and antibody fragments

- Amino-modified oligonucleotides

- Amino-linked glucans

- Functional proteins such as peptides or receptors

- Small protein fragments such as peptides

Shelf life

Stable at room temperature for up to 12 months.

Immobilization method

Binding via amino-, thiol-, hydroxyl-, and isocyanate reactive chemistry.

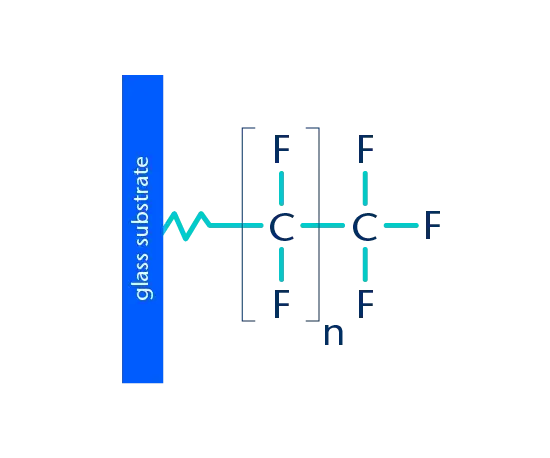

Hydrophobic coating (R&D Stage)

Product information

The coating offers a defect-free surface with a silane that yields a high contact angle (> 100° for water). A fluorinated silane is chosen without functionalities for coupling of biomolecules rendering the surface chemically inert. Produced in ISO class 7 clean room conditions using a standardized process and running a stringent quality control system, hydrophobic coating is available in standard and custom formats.

Probe types

none

Shelf life

Stable in the original sealed packaging at room temperature for up to 12 months.

Immobilization method

none

Thin-Film Nitrocellulose-Epoxy coating (NC) (R&D Stage)

The NEXTERION® NC coating is a thin and transparent nitrocellulose coating, containing reactive epoxide-groups for covalent binding of biomolecules.

Product information

With a thickness of less than 200 nm, the coating is characterized by its transparency and low autofluorescence and an excellent surface uniformity. It exhibits high sensitivity and signal-to-noise ratio and a large dynamic range especially at low probe concentration. The NC-E coating properties support small spot diameter and make the coating compatible with a variety of printing and detection methods. Produced in ISO class 5 clean room conditions using a standardized process and running a stringent quality control system, thin-film nitrocellulose-epoxy coated substrates are available in standard and custom formats.

Probe types

- Antibodies and antibody fragments

- Amino-modified oligonucleotides

- Amino-linked glucans

- Functional proteins such as peptides or receptors

Shelf life

Stable in the original sealed packaging at room temperature for up to 12 months.

Immobilization method

Binding via NC-mediated interactions and covalent binding via amine reactive chemistry (epoxy groups).

SCHOTT MINIFAB also offers microarray printing expertise.

Want to know more? Let's talk

Whether you need more information, samples, a quote, or advice for a project, I would be delighted to talk to you.