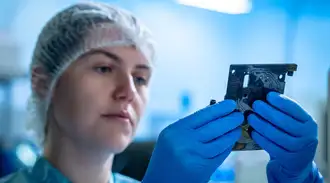

SCHOTT MINIFAB's pilot line

Accelerate your journey to manufacturing

The SCHOTT MINIFAB pilot line is a universal manufacturing platform designed to accelerate your path from idea to market. Instead of building bespoke pilot setups for every project, we’ve consolidated our core capabilities into a single, flexible infrastructure. That means the vast majority of the production environment is already in place, and only bespoke processes need to be added to bring your product to life.By using the same qualified technologies, processes, and quality systems that govern full-scale production, we reduce setup time, lower cost, and simplify scale-up. From first prototypes through process validation, early clinical trials, and into commercial launch, the pilot line adapts to your needs – providing flexibility in the early stages and a seamless transition as volumes grow.

The result is faster development, fewer risks, and a direct path to volume supply.

Supporting you at every stage of your product journey

With our universal pilot line, we can adapt quickly to your needs while maintaining the efficiency of standardized work. This means you benefit from both agility – to iterate and respond rapidly – and scale – to deliver at compelling prices. From early concepts through trials and into commercial launch, our platform provides the flexibility to evolve with your product and the stability to ensure every step is manufacturable.Developing your product

Development is the first step to realize a new product. It starts with an idea, followed by identifying user need and requirements before design testing.You're in development when you're no longer just proving an idea – you're refining how to make it real. If you've defined, or are close to defining your user requirements and device design specifications, our pilot line provides the ideal platform to explore and realize them.

We work with you to translate those requirements into a concept compatible with repeatable manufacturing processes. Through structured experimentation of design iterations, we help identify which fabrication methods best achieve your performance targets – all within a controlled, recipe-based production environment.

The outcome from development is a product design prototype that can be built on our pilot line. Every build is tracked, characterized, and consistent, giving you confidence in both the process and the pathway to scale.

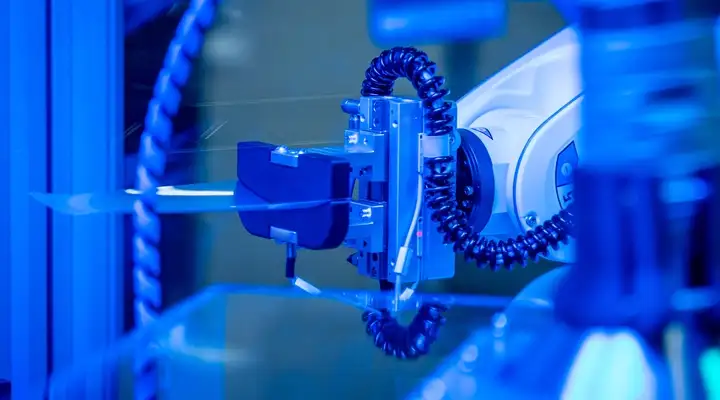

Manufacturing your product

When you’re ready to launch our pilot line delivers high-quality, compliant manufacturing at scale with no factory build-out required.Specifications are locked, process flows are defined, and cost-of-goods targets are clear. Your device is manufactured using qualified processes with validated scrap rates, cycle times, and traceability built in.

Because the same pilot line infrastructure is used throughout development, the transfer to manufacturing is seamless. Improvements are made along the way, but the line grows with you – from early builds, through trials, into commercial launch, and ultimately toward scale-up.

Most products can remain on the pilot line through clinicial trials, commercial launch and the first 3-5 years on market. Dedicated production lines are only required once you position in the market is established and volumes exceed available capacity. This approach accelerates your path to market while reducing risk and capital investment.

Access flexible capacity that moves with your demand

Find out how you can accelerate your product development journey

Would you like more information about our team, technologies or capabilities? We would be delighted to hear from you.